Understanding the intricacies of a car engine is fundamental for anyone involved in auto repair, from seasoned mechanics to aspiring DIY enthusiasts. At cardiagxpert.com, we believe that a solid grasp of engine anatomy empowers you to diagnose issues effectively and perform maintenance with confidence. This guide breaks down the essential parts of a car engine, clearly labeled and explained for optimal comprehension.

Delving into the Internal Combustion Engine

The heart of most vehicles is the internal combustion engine. This designation arises because the combustion of fuel and air occurs within the engine itself. This controlled explosion generates the force that drives pistons, which in turn, initiates the movement of your car.

Historically, the concept of internal combustion predates the more commonly known external combustion engine, like steam engines. While early attempts were made with gunpowder-based engines, it was Jean Joseph Etienne Lenoir in 1860 who patented a more practical engine using natural gas. Further advancements by Nicolaus August Otto in 1864 led to the development of the four-stroke engine, the foundational design still prevalent in modern vehicles.

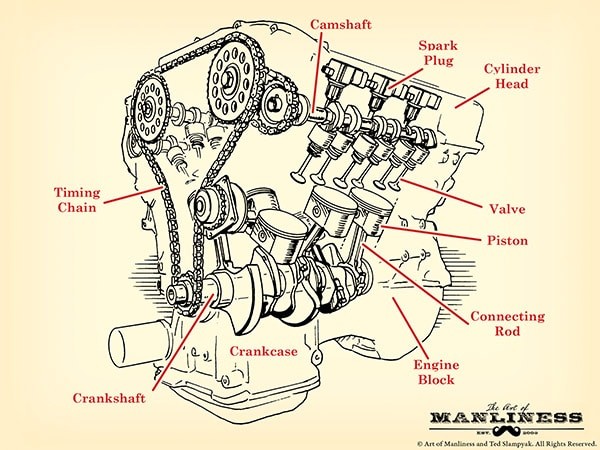

Exploring the Anatomy of a Car Engine: Labeled Components

To truly understand how an engine functions, familiarity with its components is crucial. Let’s dissect the engine and examine its key parts.

Engine Block (Cylinder Block)

The engine block, or cylinder block, serves as the structural backbone of the engine. Typically crafted from aluminum alloy or sometimes iron, it houses the cylinders – cylindrical cavities within which pistons move. The number of cylinders often dictates engine power. Beyond cylinders, the block incorporates internal passages for coolant and oil circulation, vital for engine temperature regulation and lubrication.

Decoding Engine Designations: V6, V8, and More

Engine configurations are often described by terms like “V6” or “V8,” which refer to the arrangement and quantity of cylinders. Inline engines position cylinders in a straight line. Flat engines arrange them horizontally in opposing banks. When engines exceed four cylinders, they are commonly configured in a “V” shape, dividing cylinders into two banks. A V6 engine has six cylinders in a V arrangement, while a V8 engine has eight.

Combustion Chamber

The combustion chamber is the critical space where power generation occurs. It’s where fuel, air, compression, and ignition converge to create the controlled explosion that drives the pistons. This chamber is formed by the cylinder walls, the piston top (acting as the floor), and the cylinder head (the ceiling).

Cylinder Head

The cylinder head is a metal component that seals the top of the cylinder block. It features indentations forming part of the combustion chamber. A head gasket ensures a tight seal between the cylinder head and block, preventing leaks. The cylinder head also serves as the mounting point for intake and exhaust valves, spark plugs, and fuel injectors.

Piston

Pistons are cylindrical components that reciprocate within the cylinders. Driven by combustion pressure, their downward motion is converted into rotational force. Each piston is connected to the crankshaft via a connecting rod (or con rod) and a piston pin.

Pistons are equipped with piston rings, located in grooves around their circumference. These rings, typically made of iron, include compression rings (upper rings for combustion chamber sealing) and oil rings (lower rings to prevent oil entry into the combustion chamber and regulate cylinder wall lubrication).

Crankshaft

The crankshaft is the rotating shaft that transforms the linear motion of the pistons into the rotary motion necessary to power the vehicle’s drivetrain. Positioned lengthwise within the engine block, it connects to the camshaft via belts or chains at the front and the drivetrain at the rear. Oil seals at each end prevent oil leakage.

The crankshaft resides within the crankcase, located beneath the cylinder block, which protects it and connecting rods. The lower portion of the crankcase is the oil pan, storing engine oil. An oil pump within the pan circulates oil through a filter and then to critical engine parts like crankshaft bearings, connecting rod bearings, and cylinder walls for lubrication. Balancing lobes on the crankshaft counteract vibrations, and main bearings provide smooth rotation within the engine block.

Camshaft

The camshaft is often considered the engine’s “brain,” synchronizing valve operation with piston movement via a timing belt or chain. Egg-shaped lobes along its length dictate the precise timing of valve opening and closing.

Camshaft configurations vary. Inline engines typically use a single camshaft, while V-engines may have two (one per cylinder bank) or even four (two per bank for enhanced valve control).

Timing System

The timing system, comprised of a timing belt or chain, maintains the crucial synchronization between the crankshaft and camshaft. This ensures valves open and close at the correct moments relative to piston position. Loss of synchronization, due to a skipped timing chain for instance, will disrupt engine operation.

Valvetrain

The valvetrain is the mechanical system controlling valve operation, mounted on the cylinder head. It includes valves, rocker arms, pushrods (in some designs), and lifters.

Valves

Engine valves are categorized as intake valves (allowing air-fuel mixture into the combustion chamber) and exhaust valves (allowing combustion gases to exit). Most engines utilize one intake and one exhaust valve per cylinder. High-performance engines and some standard models, like Hondas, employ multi-valve configurations (e.g., four valves per cylinder – two intake, two exhaust) for improved engine “breathing” and performance.

Rocker Arms

Rocker arms are levers that interact with the camshaft lobes. As a lobe rotates and lifts one end of the rocker arm, the opposite end presses down on the valve stem, opening the valve.

Pushrods/Lifters

In overhead valve engines, where the camshaft is positioned further from the valves, pushrods or lifters transmit motion from the camshaft lobes to the rocker arms. Overhead camshaft engines may have direct rocker arm actuation, eliminating pushrods.

Fuel Injectors

Modern engines utilize fuel injectors to deliver fuel to the combustion chamber. Replacing older carburetors, fuel injection systems offer greater precision and efficiency. Common types include:

- Direct Fuel Injection: Injectors spray fuel directly into each cylinder.

- Ported Fuel Injection: Fuel is sprayed into the intake manifold, just outside the intake valve.

- Throttle Body Fuel Injection: A single injector delivers fuel to a throttle body, where it mixes with air before distribution to cylinders.

Spark Plug

Positioned above each cylinder, the spark plug initiates combustion by generating a spark that ignites the compressed air-fuel mixture.

The Four-Stroke Cycle: Powering Your Vehicle

The coordinated interaction of these engine parts culminates in the four-stroke cycle, the sequence of events that generates power:

- Intake Stroke: The piston moves down, drawing an air-fuel mixture into the cylinder through the open intake valve.

- Compression Stroke: The piston moves up, compressing the air-fuel mixture as both intake and exhaust valves close.

- Combustion/Power Stroke: The spark plug ignites the compressed mixture, creating an explosion that forces the piston down, generating power.

- Exhaust Stroke: The piston moves up again, pushing exhaust gases out of the cylinder through the open exhaust valve.

This cycle repeats continuously in each cylinder, thousands of times per minute, propelling your vehicle.

Understanding the labeled parts of a car engine and their function is a crucial step towards automotive expertise. At cardiagxpert.com, we are dedicated to providing you with the knowledge and resources to confidently navigate the world of auto diagnostics and repair. Explore our site for more in-depth guides and tools to enhance your automotive understanding.