Checking Engine Speed Sensors with VCDS: A Comprehensive Guide

Have you ever experienced a sudden drop in engine power or a rough idle? It might be a sign of a faulty engine speed sensor. These sensors play a crucial role in determining the engine’s rotational speed and transmitting this information to the engine control unit (ECU). If the ECU receives inaccurate readings from the speed sensor, it can lead to various engine problems. In this article, we’ll delve into the process of checking engine speed sensors using VCDS, a powerful diagnostic tool for European vehicles.

Understanding Engine Speed Sensors and VCDS

What are Engine Speed Sensors?

Engine speed sensors, often referred to as crankshaft position sensors or camshaft position sensors, are critical components in a car’s engine management system. They function like an engine’s heartbeat, providing the ECU with real-time data about the engine’s revolutions per minute (RPM). This information is vital for various functions, including:

- Ignition timing: The ECU uses the speed sensor readings to determine the optimal timing for spark plugs to ignite the air-fuel mixture.

- Fuel injection: The ECU regulates the amount of fuel injected into the engine based on the engine speed.

- Transmission control: For automatic transmissions, the ECU utilizes the speed sensor data to control gear shifts.

What is VCDS?

VCDS (Vehicle Diagnostic System) is a powerful diagnostic tool commonly used by automotive technicians to diagnose and repair Volkswagen, Audi, Seat, and Skoda vehicles. It allows access to various control modules within the vehicle, enabling detailed analysis of faults, live data readings, and coding modifications. VCDS is often favored by enthusiasts and DIY mechanics due to its user-friendly interface and affordability.

Checking Engine Speed Sensors with VCDS: A Step-by-Step Guide

1. Connect to the Vehicle:

Connect your VCDS cable to the OBD-II port located under the driver’s dashboard. Once connected, start the vehicle and launch the VCDS software on your computer.

2. Select the Control Module:

Within the VCDS software, navigate to the “Select Control Module” option. Choose the engine control unit (ECU) or the relevant module containing the engine speed sensor data.

3. Access Measuring Blocks:

Within the selected control module, navigate to the “Measuring Blocks” option. You’ll find a list of different parameters available for live data readings.

4. Locate the Engine Speed Sensor Readings:

Look for the parameters related to engine speed sensors, typically labeled as “Engine Speed” or “RPM.” You might encounter variations in parameter names depending on the specific vehicle model.

5. Analyze Live Data:

Start the engine and observe the live data readings displayed for the engine speed sensor. The readings should fluctuate smoothly as the engine RPM changes. A stable reading is crucial, and any sudden spikes or erratic behavior could indicate a faulty sensor.

Here’s what to look for:

- Inconsistencies: If the readings are not synchronized with the engine’s actual RPM, it suggests a problem with the speed sensor.

- No readings: If the VCDS software fails to read any data from the speed sensor, this also signifies a possible sensor malfunction.

- Erratic Readings: Sporadic jumps or dips in readings can indicate a faulty sensor or a wiring issue.

6. Verify the Sensor:

Once you’ve identified potential issues with the engine speed sensor readings, it’s crucial to visually inspect the sensor itself. Check for loose connections, damage to the sensor housing, or corrosion on the wiring. If you find any of these issues, it’s likely that the sensor is faulty.

Troubleshooting and Repair

If you’ve confirmed a faulty engine speed sensor, the next step is to replace it. Replacing the sensor is usually a relatively straightforward process involving disconnecting the sensor from its connector, removing the old sensor, installing the new one, and reconnecting it to the wiring.

Always refer to your vehicle’s repair manual for specific instructions on replacing the engine speed sensor for your particular model.

Safety Tip:

Before working on any electrical components, always disconnect the vehicle’s battery to prevent electrical shock.

Common Questions and Concerns

Q: What are some common symptoms of a faulty engine speed sensor?

A: Besides the issues mentioned earlier, other common symptoms include:

- Difficulty starting the engine

- Engine misfiring

- Stalling at idle

- Hesitation during acceleration

- Engine warning light illuminating on the dashboard

Q: How can I be sure it’s the speed sensor and not another component?

A: A thorough diagnostic check using a tool like VCDS can help pinpoint the issue. You can also consult a qualified mechanic for a more comprehensive diagnosis.

Q: Can I replace the speed sensor myself?

A: Replacing the speed sensor is generally considered a DIY-friendly task, but it requires some basic mechanical knowledge and access to the correct tools and parts. If you’re unsure, it’s always best to seek professional assistance.

Conclusion

Checking Engine Speed Sensors With Vcds is a valuable diagnostic technique that can help you identify potential issues with your vehicle’s engine management system. By understanding the importance of these sensors and using VCDS effectively, you can proactively address problems before they escalate into more serious issues.

Remember, diagnosing and repairing automotive problems can be complex. If you’re unsure about any aspect of the process, it’s always a good idea to consult a qualified mechanic for professional assistance.

For more information on using VCDS or for any assistance with car diagnostics, feel free to contact us via WhatsApp at +84767531508.

What other questions do you have about checking engine speed sensors with VCDS? Share your thoughts in the comments below!

Engine Speed Sensor

Engine Speed Sensor

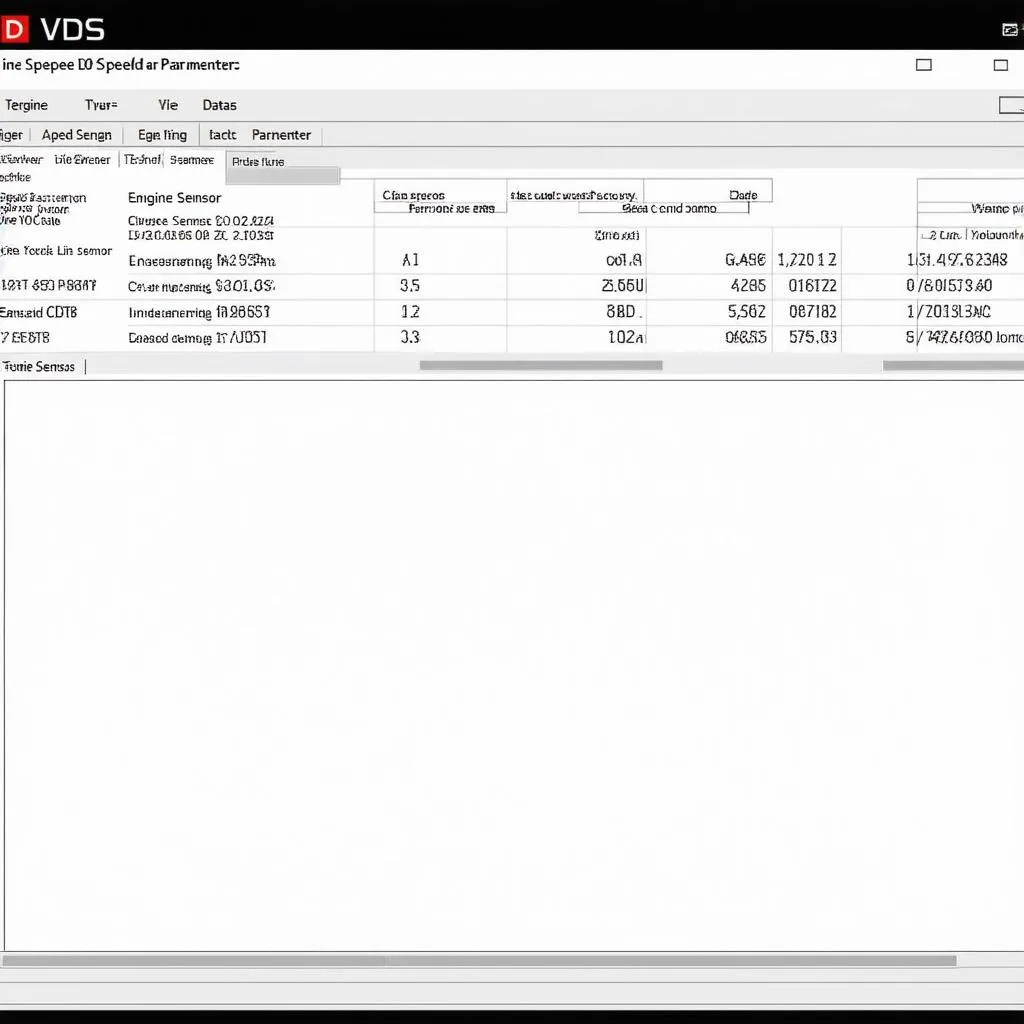

VCDS Software

VCDS Software

VCDS Cable

VCDS Cable