The chassis is the foundational structure of any vehicle, often referred to as the backbone. It’s the critical base upon which all other essential car parts are mounted. Understanding the Parts Of A Car Chassis is crucial for anyone interested in automotive repair, engineering, or simply gaining a deeper knowledge of how cars are constructed.

This article will delve into the intricate world of car chassis, exploring its functions, the various parts that constitute it, and the different designs available. Whether you’re a seasoned mechanic or a curious car owner, this guide will provide a comprehensive overview of the vital parts of a car chassis.

What is a Car Chassis?

The car chassis is fundamentally the structural framework of a vehicle. Think of it as the skeleton that supports the body and all the mechanical components. It is the primary load-bearing element, acting as the attachment point for parts such as the engine, transmission, suspension, steering, and wheels. In essence, the chassis provides the necessary rigidity and stability for all parts of a car to work together harmoniously, ensuring safe and efficient vehicle operation.

Key Functions of an Automotive Chassis

The chassis plays a multifaceted role in a vehicle’s performance and safety. Understanding these functions highlights the importance of each part of a car chassis.

Even Weight Distribution

One of the primary functions is to distribute the vehicle’s weight evenly. The chassis is designed to spread the weight across the front and rear axles, ensuring balance and stable handling. This even distribution across all wheels is vital for maintaining equilibrium, especially during cornering and braking.

Crash Energy Absorption and Distribution

In the unfortunate event of a collision, the car chassis is engineered to absorb and distribute crash energy. Specific zones within the chassis are designed to crumple and deform in a controlled manner. This process absorbs impact forces and distributes them throughout the chassis structure, minimizing damage to the passenger cabin and reducing the risk of injury to occupants. The strategic design of parts of a car chassis is critical for effective crash energy management.

Foundation for Vehicle Components

The chassis serves as a rigid foundation for mounting all other car components. It provides secure attachment points for the steering system, suspension, braking system, wheels, engine, and transmission. Essentially, every major system within a vehicle relies on the chassis for support and correct positioning. The precise integration of these parts of a car chassis is essential for the overall functionality of the vehicle.

Structural Integrity and Balance

Beyond supporting individual components, the chassis is crucial for maintaining the overall structural integrity and balance of the vehicle. It supports the weight of the engine, drivetrain, and body while providing a stable platform for the suspension, brakes, and steering systems to operate effectively. Furthermore, the chassis contributes to dampening vibrations, noise, and harshness, leading to a smoother and more comfortable ride. Some chassis designs are even optimized for enhanced handling, particularly in off-road vehicles.

Essential Parts of a Car Chassis: An In-depth Look

While the specific design can vary, most car chassis share a set of common parts. Let’s explore these components in detail:

Frame Rails

Frame rails are the backbone of the chassis structure. These longitudinal beams, typically made of steel or aluminum, run along the length of the vehicle. They are the primary load-bearing members, providing the chassis with its strength and rigidity. Frame rails are fundamental parts of a car chassis, supporting the vehicle’s weight and resisting bending and twisting forces.

Cross Members

Cross members are structural beams that run horizontally, connecting the frame rails. They add significant rigidity and stability to the chassis, preventing the frame rails from twisting or collapsing. Cross members also serve as mounting points for various components like the engine, transmission mounts, and suspension elements. These essential parts of a car chassis enhance overall structural integrity.

Suspension System

The suspension system is a critical set of parts of a car chassis that connects the wheels and axles to the chassis frame. It includes components like springs, shock absorbers, linkages, and control arms. The suspension system’s primary function is to maintain contact between the tires and the road surface, ensuring stable handling and a comfortable ride. It absorbs shocks and vibrations from uneven road surfaces, preventing them from being transmitted directly to the chassis and the vehicle occupants.

Braking System

The braking system, although mounted to the chassis, is an independent yet crucial system. It works in conjunction with the wheels and suspension to slow down or stop the vehicle. Key parts of a car chassis related to braking include mounting points for brake calipers, rotors (or drums), and brake lines. The braking system uses friction to convert kinetic energy into heat, effectively slowing the vehicle.

Steering System

Similar to the braking system, the steering system is attached to the chassis and works with the suspension and wheels to control the vehicle’s direction. Parts of a car chassis relevant to steering include mounting points for the steering rack or gearbox, steering linkages, and the steering column. The steering system allows the driver to direct the wheels and maneuver the vehicle.

Wheels and Tires

Wheels and tires are the only parts of a car chassis that make direct contact with the road. They are essential for providing traction, stability, and shock absorption. While not structurally part of the chassis frame itself, their connection and performance are intrinsically linked to the chassis design and suspension system.

Transmission System

The transmission system is directly linked to the chassis through transmission mounts. It works in tandem with the engine and driveline to deliver power to the wheels efficiently. Parts of a car chassis interact with the transmission by providing secure mounting points and contributing to vibration dampening. The transmission system includes the gearbox and related components responsible for gear shifting and power delivery.

Clutch

In vehicles with manual transmissions, the clutch is a vital component. It connects and disconnects the engine from the transmission, allowing for smooth gear changes and preventing engine stalling during shifting. The clutch assembly is typically mounted in close proximity to the chassis and is considered one of the important parts of a car chassis system when considering powertrain integration.

Rear Axle

The rear axle is a critical part of a car chassis, particularly in rear-wheel-drive and four-wheel-drive vehicles. It transmits power from the drivetrain to the rear wheels, generating the torque needed to propel the vehicle. The rear axle also supports the rear wheels and suspension components, enabling vehicle movement and directional control.

Universal Joint

The universal joint is a flexible coupling connector situated between the transmission and the driveshaft, often near the front axle in some configurations. It’s a crucial part of a car chassis system in vehicles with driveshafts. It allows the driveshaft to rotate at different angles while transmitting power, accommodating suspension movement and chassis flex.

Types of Car Chassis

Car chassis designs have evolved over time, resulting in several distinct types, each with its own advantages and disadvantages. The choice of chassis type often influences the configuration and arrangement of parts of a car chassis.

Ladder Frame Chassis

The ladder frame chassis is a traditional design characterized by two parallel frame rails connected by cross members, resembling a ladder. This robust design provides a strong and rigid foundation, making it suitable for heavy-duty vehicles like trucks and SUVs. The simple construction of ladder frame chassis makes them relatively easy to manufacture and assemble.

Pros

- Simple and easy to manufacture

- High structural integrity

- Robust and suitable for heavy loads

Cons

- Heavy, not ideal for lightweight vehicles

- Lower torsional rigidity compared to other designs

Monocoque Chassis

The monocoque chassis, also known as unibody construction, integrates the body and chassis into a single unit. This design is prevalent in modern passenger cars, including sedans, hatchbacks, and SUVs. Monocoque chassis offer excellent strength, rigidity, and improved crash safety due to their ability to distribute impact forces effectively.

Pros

- High torsional rigidity

- Enhanced safety and crash resistance

- Lighter than ladder frame chassis

Cons

- More complex and expensive to manufacture

- Repairs can be more challenging

Backbone Chassis

The backbone chassis features a strong central tube, often cylindrical, that connects the front and rear axles. This “backbone” provides the primary structural support, offering high torsional stiffness. Backbone chassis are often found in off-road vehicles due to their robustness and ability to handle torsional forces.

Pros

- Excellent torsional rigidity

- Strong and rigid foundation

- Suitable for off-road vehicles

Cons

- Higher manufacturing costs

- Driveshaft issues can affect the entire chassis integrity

Tubular Chassis

Tubular chassis, also known as space frame chassis, utilize a network of interconnected tubes to create a three-dimensional structure. This design offers an exceptional strength-to-weight ratio, making it popular in high-performance and racing cars. Tubular chassis allow for design flexibility and customization, but are more complex to fabricate.

Pros

- Excellent strength-to-weight ratio

- High crash resistance

- Design flexibility and customization

Cons

- Complex and challenging to manufacture

Materials Used in Car Chassis Parts

The selection of materials for parts of a car chassis is crucial, balancing factors like strength, weight, cost, and corrosion resistance.

Steel

Steel has traditionally been the dominant material due to its high strength, durability, and cost-effectiveness. It’s readily machinable and provides excellent structural integrity. However, steel is heavier and more susceptible to corrosion compared to some alternatives. Different grades of steel, including high-strength steel and alloy steels, are used in various parts of a car chassis to optimize performance and weight.

Aluminum

Aluminum is increasingly used in chassis construction due to its lightweight nature and good strength-to-weight ratio. Aluminum alloys offer improved corrosion resistance and contribute to better fuel efficiency and handling. While more expensive than steel, aluminum is favored in performance vehicles and EVs where weight reduction is paramount. Aluminum is used in frame rails, cross members, and other structural parts of a car chassis.

Magnesium Alloys

Magnesium alloys are even lighter than aluminum, making them attractive for high-performance and racing applications. However, magnesium alloys can be less corrosion-resistant and more expensive. They are often alloyed with aluminum (like AZ91D) to improve properties. Limited parts of a car chassis are made from magnesium alloys due to cost and corrosion concerns.

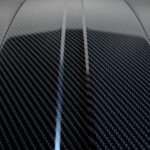

Composites

Composite materials, such as carbon fiber and fiberglass, are gaining traction in automotive chassis manufacturing. Composites offer exceptional strength, stiffness, and lightweight properties. They are also corrosion-resistant and can be molded into complex shapes. However, composites are currently more expensive and challenging to manufacture at high volumes, primarily used in high-end and racing vehicles for specific parts of a car chassis or even entire monocoque structures.

Manufacturing Processes for Chassis Parts

Creating the various parts of a car chassis involves a range of manufacturing processes, each suited for specific components and materials.

CNC Machining

CNC (Computer Numerical Control) machining is a precise subtractive manufacturing process. It utilizes computer-controlled cutting tools to remove material from a solid block to create the desired shape. CNC machining is ideal for producing complex and intricate parts of a car chassis with high accuracy, such as suspension components, steering parts, and mounting brackets. It works well with various materials, including aluminum, steel, and composites.

Sheet Metal Fabrication

Sheet metal fabrication encompasses processes like cutting, bending, stamping, and welding metal sheets to create various chassis components. This versatile method is used to produce parts like cross members, frame reinforcements, and body panels that integrate with the chassis. Sheet metal fabrication is efficient and cost-effective for producing many parts of a car chassis from steel and aluminum.

Die Casting

Die casting is a process where molten metal is injected under high pressure into a mold cavity. It’s suitable for mass production of complex-shaped metal parts with good dimensional accuracy. Die casting is often used to manufacture engine cradles, suspension links, and other structural parts of a car chassis, particularly from aluminum alloys. While tooling costs are high, die casting is economical for large production volumes.

Finishing Options for Chassis Parts

Surface finishing is crucial for protecting parts of a car chassis from corrosion, enhancing durability, and improving aesthetics, even though the chassis is not typically visible.

Anodizing

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of metals, particularly aluminum. Anodized coatings enhance corrosion resistance, wear resistance, and provide a decorative finish. Anodizing is commonly used for aluminum chassis components to improve their durability and appearance.

Painting

Painting is a widely used finishing method for steel chassis components. Applying paint coatings provides a barrier against moisture and corrosive elements, preventing rust and extending the lifespan of the chassis. Paints can also include additives for enhanced corrosion protection and durability.

Galvanizing

Galvanizing involves coating steel parts of a car chassis with a layer of zinc. This process provides excellent corrosion protection, as zinc acts as a sacrificial anode, preventing rust even if the coating is scratched. Galvanizing is commonly used for frame rails and other structural steel components exposed to harsh environments.

Polishing

Polishing is a surface finishing process that uses abrasives to create a smooth and glossy finish. While primarily for aesthetics, polishing can also remove minor imperfections and improve corrosion resistance by eliminating crevices where corrosives can accumulate. Polishing might be used for visible parts of a car chassis in custom or high-performance vehicles.

Future Design Trends for Automotive Chassis Systems

Automotive chassis design is continuously evolving, driven by demands for improved performance, safety, and sustainability. Future trends will likely impact the design and materials used for parts of a car chassis.

Weight Reduction

Reducing vehicle weight is a major trend to improve fuel efficiency and performance, especially in electric vehicles. Future chassis designs will increasingly utilize lightweight materials like aluminum, composites, and high-strength steel alloys. Optimization of chassis structure and part design will also contribute to weight reduction.

Enhanced Safety Features

Safety remains a paramount concern. Future chassis designs will incorporate advanced safety features like improved crumple zones, optimized load paths for crash energy management, and integration with advanced driver-assistance systems (ADAS). The design of parts of a car chassis will be crucial in implementing these enhanced safety features.

Integration With Electric Powertrains

The rise of electric vehicles is driving significant changes in chassis design. EV chassis need to accommodate large battery packs, electric motors, and related electronics. Chassis platforms are being developed specifically for EVs, optimizing space utilization, weight distribution, and battery pack integration. The layout and mounting of parts of a car chassis are being redesigned to suit electric powertrains.

Modular Chassis Platforms

Modular chassis platforms are gaining popularity as a cost-effective and flexible approach to vehicle development. These platforms allow manufacturers to build various vehicle models on a single chassis architecture, reducing development time and costs. Modular designs facilitate the integration of different powertrains, including internal combustion engines, hybrids, and electric systems, by using interchangeable parts of a car chassis and modules.

WayKen: Your Expert Partner for Automotive Car Parts

Whether you need standard automotive components or specialized parts of a car chassis, WayKen is your trusted partner for high-quality automotive part manufacturing. We offer expertise in producing a wide range of parts, from simple brackets to complex chassis components. With advanced technology and a skilled team, WayKen ensures precision, reliability, and adherence to strict quality standards. From prototyping to mass production, we deliver automotive parts that meet your specific needs. Choose WayKen for exceptional quality and service in automotive component manufacturing.

Conclusion

The car chassis is far more than just a frame; it is the foundational structure that integrates and supports all critical vehicle systems. Understanding the functions and parts of a car chassis is essential for appreciating vehicle design, engineering, and repair. As automotive technology advances, chassis design will continue to evolve, driven by the pursuit of improved performance, safety, and sustainability.

FAQs

Are car frames the same as car chassis?

No, while often used interchangeably, the frame is a primary structural component of the chassis. The car chassis encompasses the frame and all the systems mounted upon it, including suspension, steering, and drivetrain components. The frame is a key part of a car chassis, but not the entirety of it.

Which car chassis is best for high-performance vehicles?

For high-performance vehicles, the monocoque and tubular chassis designs are generally preferred. Monocoque chassis offer a good balance of rigidity and weight, while tubular chassis provide the ultimate strength-to-weight ratio, making them ideal for racing and high-performance applications. The optimal choice depends on specific performance requirements and design considerations of the vehicle.