You might be surprised to find EV coverage on CarBuzz, especially if you thought we’d abandoned our love for V8 engines. Rest assured, that’s not the case. While we appreciate new technology and recognize EVs as part of the future of mobility, the CarBuzz team holds a deep admiration for V8 engines and their significance in the world of high-performance cars.

We’ve extensively covered the most powerful V8s from American manufacturers, as well as impressive V8s from Japanese, German, and even South Korean automakers. However, we’ve yet to delve into the most potent V8 engine originating from Great Britain. Prepare to be amazed by a technological masterpiece: a V8 producing a staggering 916 horsepower, set to debut in the highly anticipated Mclaren W1.

McLaren W1 Key Specs

| Feature | Specification |

|---|---|

| Base MSRP | $2,100,000 |

| Base Trim Engine | 4.0-liter MHP-8 V8 & e-module |

| Transmission | 8-speed dual-clutch automatic |

| Horsepower | 1,258 hp |

| Torque | 988 lb-ft |

| Dry Weight | 3,084 lbs |

| 0-60 MPH | 2.7 seconds |

| Top Speed | 217 mph |

Before the McLaren W1 hits production, CarBuzz was granted an exclusive in-depth look at the revolutionary MHP-8 engine and hybrid powertrain. This groundbreaking technology is poised to make the McLaren W1 the fastest McLaren road car ever, setting new benchmarks for track performance. Here’s a detailed breakdown of what we discovered.

A Revolutionary V8 Engine for a New Era of Performance

McLaren has been a pioneer in adopting hybrid technology for performance enhancement. The P1 offered an early glimpse into this future, coinciding with the arrival of the Ferrari LaFerrari and Porsche 918 Spyder. Now, McLaren is continuing this innovative approach with the W1, combining a hybrid system with a 4.0-liter twin-turbo V8 to unleash an astounding 1,258 horsepower and 988 lb-ft of torque. Power is delivered exclusively to the rear wheels, resulting in breathtaking acceleration figures: 0-60 mph in 2.7 seconds, 0-124 mph in 5.8 seconds, and 0-186 mph in under 12.7 seconds. These are remarkable numbers for a rear-wheel-drive hypercar. However, reducing the McLaren W1, especially its brand-new V8 engine, to mere statistics would be a profound understatement of its engineering brilliance.

Related Article: How McLaren’s Most Power-Dense V8 Engine Ever Stacks Up Against Hypercar Royalty

The McLaren W1, successor to the P1, is powered by the most power-dense V8 engine McLaren has ever engineered. But how does this engine compare to those of other contemporary hypercars?

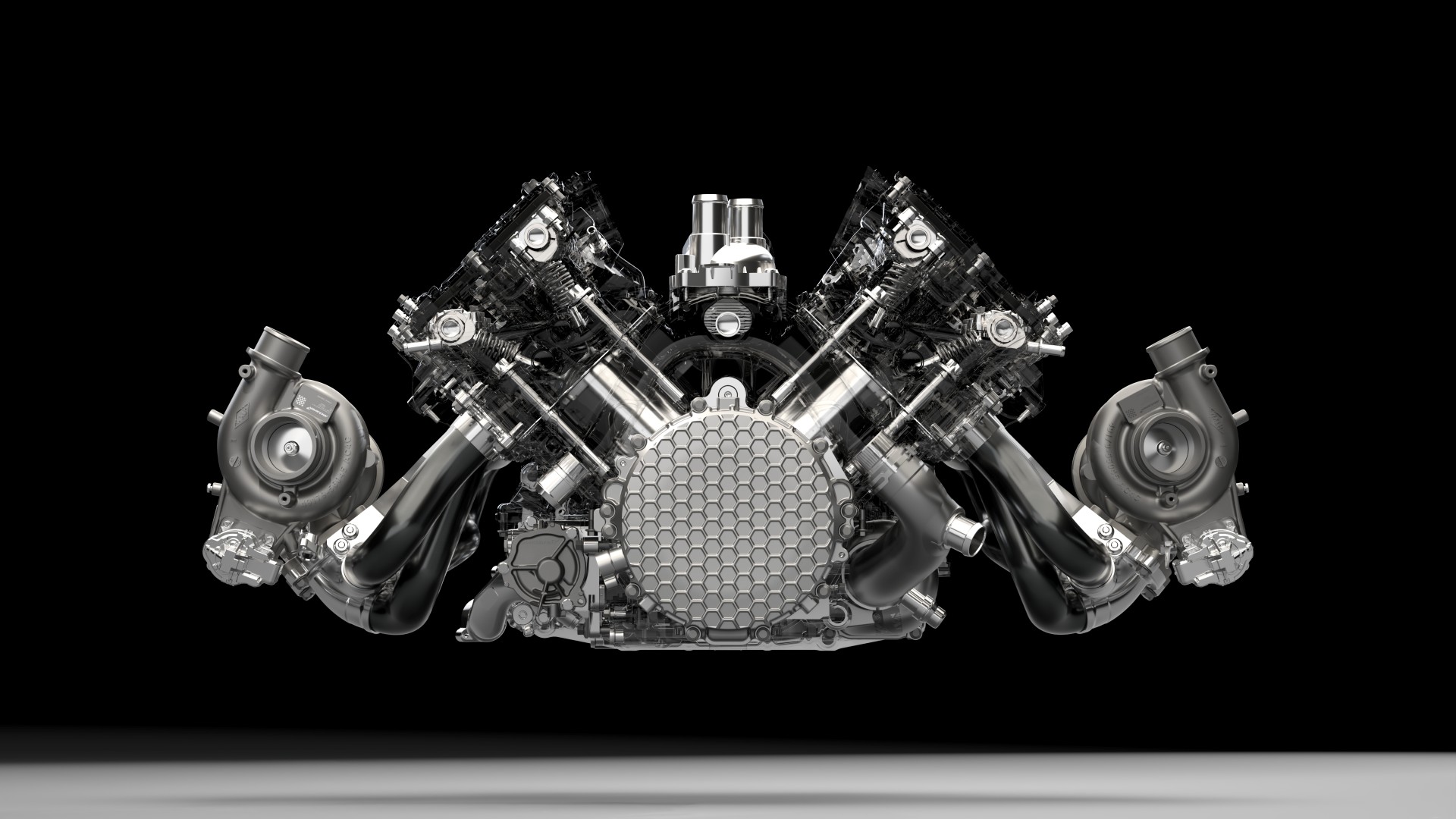

The MHP-8 V8 engine, the heart of the McLaren W1, shares a basic architecture, displacement, and twin-turbo configuration with the M840T V8 found in other McLaren models, including the award-winning 750S. However, the similarities largely end there. This is a completely new design, an engine conceived from the ground up. McLaren initiated the design process in 2020, carefully evaluating the optimal powertrain for the P1 successor. While a V6 might have aligned with McLaren’s Formula 1 heritage, and a V10 could have offered unique exclusivity, McLaren ultimately concluded, based on extensive data analysis, that a twin-turbo V8 provided the ideal balance of power and weight. This configuration also ensured exceptional drivability and, crucially, preserved the emotional engagement expected from a McLaren hypercar.

“We explored every conceivable configuration – cylinder count, capacity – but when we distilled it down to the required performance level, the high-revving nature we desired, and the packaging constraints to maintain a set wheelbase and manage weight distribution, we quickly converged back to this V8 as the optimal solution for a vehicle like the McLaren W1.”

- Richard Jackson, McLaren Chief Engineer, Propulsion

Compact V8 Engine with Advanced 3D-Printed Components

The new V8 engine in the McLaren W1 is not only more powerful and higher-revving but also more compact than any previous McLaren V8. This achievement is due to the incorporation of cutting-edge technologies that enhance compactness and robustness. While the fundamental layout – a 90-degree flat-plane crank V8 with twin turbos – is conventional, this is not a ‘hot-vee’ design. Instead, the turbos are positioned outside the cylinder banks, resulting in a shorter powertrain height. Beyond height reduction, the engine’s length is also reduced by 30mm (approximately 1.2 inches). McLaren achieved this compactness by minimizing bore spacing and employing 3D printing (additive manufacturing) for water jacket cores, replacing traditional sandcasting. This innovative approach optimizes material usage, reducing it where unnecessary and maximizing it for structural reinforcement.

“Utilizing 3D-printed cores in the water jacket allows us to direct coolant precisely behind the most thermally stressed areas of the cylinder head, far more effectively than conventional sand casting. This enhanced cooling extends the engine’s knock limit.”

- Richard Jackson, McLaren Chief Engineer, Propulsion

| McLaren MHP-8 Engine Specifications |

|---|

| Configuration |

| Displacement |

| Bore |

| Stroke |

| Power (Combustion Engine) |

| Power (Electric Motor) |

| Combined Power |

| Torque (Combustion Engine) |

| Torque (Electric Motor) |

| Combined Torque |

| Specific Output |

The MHP-8 engine represents a significant advancement over the M840T in virtually every metric. Despite its increased power output, it is also lighter. The engine itself weighs 22 lbs less than the M840T, thanks to weight-saving measures such as hollow camshafts, a glass-fiber-reinforced plastic air intake manifold integrated within the engine’s vee, and the elimination of the starter motor and alternator, functions now handled by the hybrid system.

“Because this engine is designed for hybrid applications, we eliminate the need for a starter motor and alternator, resulting in substantial weight savings. However, our focus isn’t solely on lightness; robustness is equally critical. Extensive CAE optimization for strength is complemented by thousands of hours of dyno testing to ensure product durability. This is an entirely new powertrain, not just a new engine.”

- Richard Jackson, McLaren Chief Engineer, Propulsion

Advanced Fuel Injection System: Port and Direct Injection Synergy

Fuel delivery in the MHP-8 engine has undergone substantial refinement, with McLaren opting for a combination of gasoline direct injection (GDI) and port fuel injection (PFI). While computational fluid dynamics (CFD) is commonly used for aerodynamic enhancements, McLaren employed it to optimize fuel spray patterns within the combustion chamber. This optimization leads to superior fuel atomization, promoting cleaner combustion and maximizing power extraction from each drop of fuel. The fuel injection systems operate at extremely high pressures, with the GDI system reaching 5,000 psi.

By precisely managing the air-fuel ratio and its distribution relative to the spark plug, McLaren has improved emissions and significantly accelerated the warm-up time of catalytic converters during cold starts. “We heavily emphasized cold start emissions by creating the ideal air-fuel mixture very close to the spark plug during cold starts,” Richard Jackson explains. This approach “yields very stable combustion, allowing us to retard combustion, which directs more heat into the exhaust, enabling much faster and more effective catalyst heating compared to previous engines.”

Furthermore, fuel is not injected into the combustion chamber in a single burst. McLaren utilizes triple injection – three fuel spurts per stroke – to optimize fuel distribution and minimize fuel accumulation on combustion chamber walls.

The PFI system is reserved for engine operation under extremely high loads. “We’ve employed PFI in a way that differs from typical OEM applications,” Jackson explains, noting that McLaren uses it “only at very high speed, high load operation to provide extra performance.” By limiting PFI to high-load scenarios, McLaren optimizes the GDI system for efficiency, adding supplemental fuel only when the engine demands it most. With a redline of 9,200 rpm – exceeding that of the Porsche 918 Spyder – the MHP-8 engine will frequently require maximum fuel delivery within extremely short timeframes.

“In a high-revving engine like this, you have approximately 15 milliseconds to draw air into the cylinder, inject and mix fuel, ignite it, generate power, and expel exhaust gases. Effectively, we’re completing this cycle ten times faster than the blink of an eye.”

Twin-Scroll Turbos for Optimized Response

In any forced induction engine, the turbocharger system critically influences engine performance. Rather than adopting electrified turbocharging, as seen in Porsche and other manufacturers, McLaren opted for a more conventional turbocharger setup, utilizing twin-scroll turbos to efficiently manage airflow in the McLaren W1.

“We chose a twin-scroll turbo design, which significantly improves transient response by separating exhaust pulses,” Jackson states. “Our focus wasn’t solely on peak power. Achieving peak power with a large turbo is relatively straightforward, but it often compromises transient response. We challenged our turbo supplier to maximize boost at low flow and low engine speeds, alongside achieving peak performance. The resulting torque curve speaks volumes.”

While the McLaren W1 represents cutting-edge technology, why not employ electric turbos? McLaren considered electric turbos, Jackson explains, “but ruled them out for several reasons.” The primary reasons were weight – electric turbochargers are heavier than traditional ones – and McLaren’s assessment of the trade-offs between electric turbos and an electric motor directly powering the drivetrain. They concluded that the latter offered a more advantageous solution. “Electric turbos are quite heavy, and when we evaluated the performance potential, this e-module can deliver approximately 350 horsepower instantaneously. We can achieve quicker performance gains with this approach, making it a more effective use of battery power.”

On the intake side, the intake manifold features remarkably short runners and low volume compared to conventional designs. This design further optimizes engine responsiveness, minimizing turbo lag by reducing air inertia within the manifold.

A Hybrid System Engineered for Performance

During the McLaren W1 presentation, various components, including the e-module and battery, were showcased. The battery, as previously mentioned, incorporates learnings from the Speedtail project and is nearly identical in design to the upgraded P1 battery pack McLaren offered P1 owners post-production. This lightweight battery (110 lbs) with a 1.384 kWh capacity is designed for rapid discharge and recharge, eliminating the need for plug-in charging. While the battery represents advanced technology, the e-module is arguably the standout feature.

The e-module integrates a radial flux motor and a motor control unit within a single compact housing weighing just 44 lbs. The motor itself weighs a mere 33 lbs and delivers 342 hp and 324 lb-ft of torque – performance comparable to an entire hot hatchback within a component a child could lift. This e-module is 50% lighter than the one used in the Speedtail, and the complete hybrid system is 88 lbs lighter than the P1’s system while generating 90% more power.

The radial flux e-motor also differs from the motor used in the Artura. The Artura employs an axial flux motor sandwiched between the engine and transmission. In contrast, the McLaren W1 uses an entirely different motor type mounted downstream of the clutch system, directly bolting to the new 8-speed dual-clutch automatic transmission and eliminating the need for a reverse gear. According to Jackson, “clutches are typically the torque-limiting factor in transmissions.” By positioning the e-motor after the clutches, the McLaren W1 can significantly increase total torque output without risking transmission damage.

Related Article: 10 Things Everybody Should Know About Dual-Clutch Transmissions

If you want to maximize your car’s dual-clutch transmission performance, here are key things you should know.

Even more ingeniously, the e-motor powers the even-numbered gears, establishing a parallel power delivery system. “The e-motor, mounted on the transmission’s side, engages through the even gears while the internal combustion engine can engage through any of the eight forward gears,” Jackson explains. In a DCT, two input shafts exist: one for odd gears and one for even gears. The e-motor connects to the even-gear input shaft, enabling it to operate through four ratios independently or to contribute additional torque alongside the V8 engine.

The Undisputed Fastest McLaren on Any Circuit

The McLaren W1’s powertrain is a marvel of engineering and packaging. Despite its technological complexity, McLaren prioritized driver engagement, meticulously refining the engine’s sound. Using anechoic chambers, acoustic cameras, and bespoke exhaust manifold tuning to optimize fourth-order sounds, McLaren has crafted an aural crescendo that entices drivers to explore the engine’s 9,200-rpm redline.

Of course, the McLaren W1’s appeal extends beyond its auditory experience; it is also incredibly fast. McLaren asserts that the W1 will be the fastest road-legal McLaren around any racetrack. In internal benchmark testing at the Nardo test track, this claim has already been substantiated. Marcus White, Head of Performance Attributes, reports that the McLaren W1 is three seconds faster around the Nardo track than the next quickest McLaren – equivalent to an 800-foot lead. In a straight-line acceleration test to 186 mph, the W1 reached that speed three car lengths ahead of its closest competitor.

Time will reveal if the McLaren W1 will live up to the legacy of its predecessors – the iconic McLaren F1 and the legendary P1. However, the glimpse we’ve had into its groundbreaking powertrain confirms it is a technological marvel deserving of immense respect. And it proudly holds the title of featuring Britain’s most powerful V8 engine ever in a road car. That distinction undoubtedly carries significant weight.