A car engine is the powerhouse of your vehicle. Much like the human heart, it’s a complex assembly responsible for generating the motion that gets you from point A to point B. Often referred to as an internal combustion engine (ICE), it operates through a sophisticated series of pistons and cylinders, converting fuel into the driving force that turns your wheels.

While many drivers think of the engine as a single unit, it’s actually a collection of numerous interconnected parts working in perfect synchronicity. You might recognize some Car Engine Parts Names, but understanding their individual roles and interactions within the engine is essential for any car owner.

This comprehensive guide will walk you through the essential car engine parts, explaining their functions and how they contribute to your vehicle’s overall performance. Whether you’re a seasoned mechanic or just starting to learn about cars, this guide will deepen your understanding of what’s under the hood.

Understanding the Heart of Your Car: What is a Car Engine?

The engine is undeniably the core component of your car. It’s a marvel of engineering designed to transform the heat energy from burning fuel into the mechanical energy that propels the wheels.

This transformation begins with a spark, initiating a controlled explosion of a precisely mixed vapor of fuel and compressed air within a sealed cylinder. This rapid burning process, known as internal combustion, generates expansion and force, which ultimately provides the power to move your car. Hence the name: internal combustion engine.

To endure the demanding conditions of continuous operation, the engine is built with robust construction. It is fundamentally divided into two main sections. The lower, heavier section is the cylinder block, which acts as the main housing for the engine’s moving parts. The upper, detachable section is the cylinder head.

The cylinder head is crucial for managing the flow of gases. It incorporates valve-controlled passages that allow the air and fuel mixture to enter the cylinders and separate passages for expelling the exhaust gases after combustion.

Within the engine block resides the crankshaft. This vital component converts the linear, up-and-down motion of the pistons into the rotary motion needed to power the drivetrain.

Frequently, the engine block also houses the camshaft. The camshaft controls the mechanisms that precisely open and close the valves within the cylinder head, regulating the intake and exhaust processes. In some engine designs, the camshaft is located in the cylinder head or mounted above it, optimizing valve control.

Decoding the Process: How a Car Engine Works

Similar to how our bodies convert food into energy, a car engine converts gasoline into motion. Modern hybrid vehicles also incorporate electric power from batteries, but the fundamental principle of internal combustion remains central to most cars on the road today.

The process of converting gasoline to motion is termed “internal combustion.” Combustion, or burning, is the fundamental chemical reaction that releases energy from a fuel-air mixture.

In an internal combustion engine (ICE), the ignition and combustion of fuel occur directly inside the engine. The engine then harnesses a portion of the energy released by combustion and transforms it into mechanical work.

The core of the engine consists of a fixed cylinder and a mobile piston. The expanding gases from combustion exert pressure, pushing the piston downwards. This linear motion of the piston is then converted into rotational motion by the crankshaft. This rotational force is finally transmitted to the vehicle’s wheels through a gear system within the powertrain.

Imagine a controlled explosion within a confined space, like the piston in an engine. This explosion releases a tremendous amount of energy in the form of expanding gas. A typical car engine generates these controlled explosions hundreds of times every minute. The engine is designed to capture and utilize this energy to power your vehicle.

These explosions force the pistons to move rapidly within the engine. As the force of one explosion diminishes, another occurs, continuing the cycle and maintaining the piston’s motion. This continuous cycle provides the sustained power needed to drive the car.

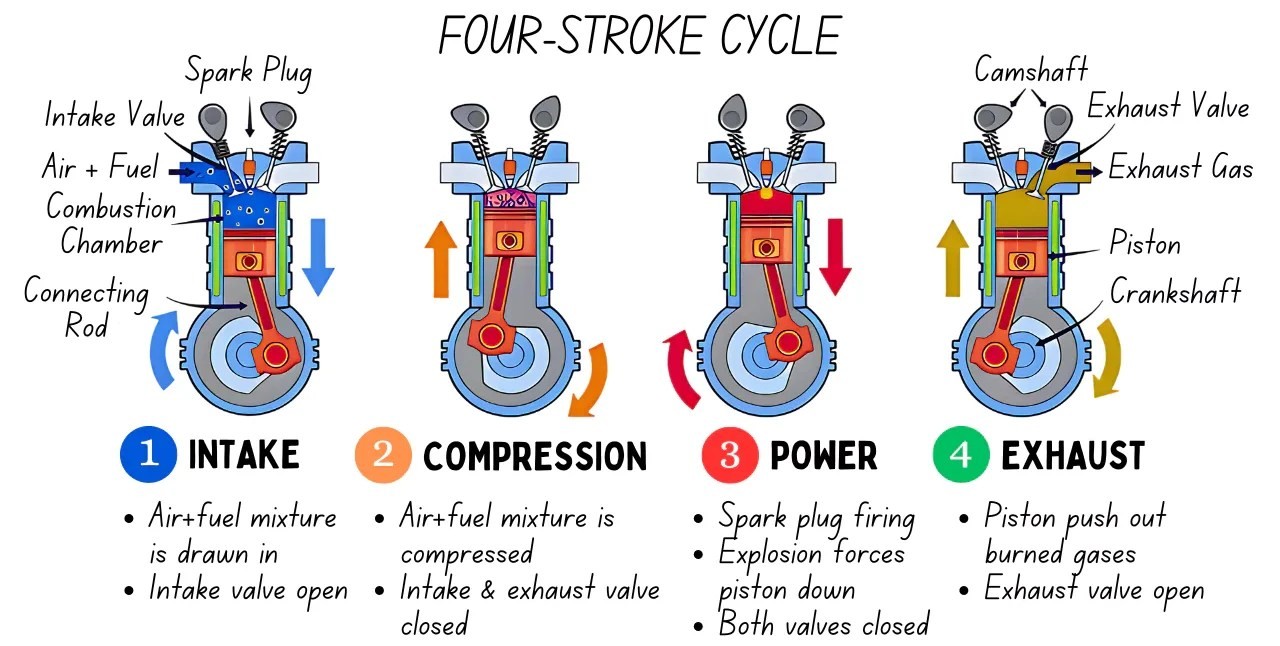

Car engines operate using a four-stroke combustion cycle. These four strokes—intake, compression, combustion (power), and exhaust—repeat continuously to generate power. Let’s examine each stroke in detail.

#1. Intake Stroke

- The piston moves downwards within the cylinder bore, traveling from Top Dead Center (TDC) to Bottom Dead Center (BDC).

- The inlet valve opens, allowing the air-fuel mixture to enter, while the outlet valve remains closed.

- The downward motion of the piston creates a vacuum, drawing the air-fuel mixture into the engine cylinder through the open intake valve.

#2. Compression Stroke

- The piston moves upwards in the cylinder bore from BDC to TDC.

- Both the inlet and outlet valves are closed, sealing the cylinder.

- The upward movement of the piston compresses the air-fuel mixture within the combustion chamber, increasing its temperature and pressure.

#3. Power Stroke (Combustion)

- The spark plug ignites the highly compressed air-fuel mixture just before the piston reaches TDC at the end of the compression stroke.

- This ignition causes a powerful combustion, forcing the piston downwards into the cylinder bore and rotating the crankshaft. This powerful downward force is what propels the vehicle forward.

- Both inlet and outlet valves remain closed during this stroke to maximize the power generated.

#4. Exhaust Stroke

- The piston moves upwards again in the cylinder bore from BDC to TDC. Momentum from the power stroke keeps the crankshaft rotating, driving this and the other strokes.

- The inlet valve closes, and the outlet valve opens.

- The upward movement of the piston pushes the spent combustion gases out of the cylinder through the open exhaust valve. The cycle is now complete, and the piston is ready to begin the intake stroke again.

- These exhaust gases are then directed to the catalytic converter for cleaning, and subsequently through the muffler before exiting the vehicle via the tailpipe.

The precise opening and closing of the intake and exhaust valves are controlled by cams on a camshaft, which is driven by a timing belt or chain connected to the engine’s crankshaft. This synchronized movement ensures the engine operates efficiently.

In multi-cylinder car engines, the combustion cycles in each cylinder are carefully staggered to ensure smooth and balanced power delivery. This prevents simultaneous combustion strokes, resulting in a quieter and more stable engine operation.

However, it’s important to note that gasoline engines are not perfectly efficient. On average, they convert only about 20% of the fuel’s chemical energy into mechanical energy. Of this, only about 15% is ultimately used to propel the wheels, with the remaining energy lost due to friction, heat, and other mechanical inefficiencies.

Now, let’s delve into the specific parts that work in concert to enable this intricate process. You might have encountered some of these car engine parts names before, but understanding their precise roles and relationships within the engine is key to appreciating the complexity and ingenuity of automotive engineering.

Car Engine Parts Names with Diagram: Visualizing the Components

To better understand the location and appearance of each engine component, let’s examine a car engine parts diagram showcasing the main parts. Refer to the diagram below to visualize the placement of each part and gain a clearer understanding of engine anatomy.

These diagrams typically illustrate components such as the engine block, combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valves, rocker arms, pushrods/lifters, injectors, spark plugs, oil pan, distributor, connecting rods, piston rings, and flywheels. Becoming familiar with these names and their positions is a great first step in understanding engine mechanics.

Comprehensive List of Car Engine Parts Names

While we often refer to the engine as a single unit, it’s crucial to remember it’s an assembly of many individual parts working together. Let’s explore a more detailed list of car engine parts names to expand your knowledge.

Expanded List of Car Engine Parts Names:

- Distributor o-ring

- Cylinder headcover

- Rubber grommet

- Camshaft pulley

- Oil filter

- Water pump

- Timing belt drive pulley

- Oil pan drain bolt

- Turbocharger and supercharger

- Starter motor

A typical internal combustion engine contains around 200 parts that require maintenance and potential replacement over their lifespan. In contrast, electric vehicles significantly reduce this complexity, with approximately 20 main parts in their electric drive systems.

However, for the purpose of this guide, we will focus on the primary parts of a car engine to provide a solid foundational understanding.

Essential Parts of A Car Engine: Functions and Symptoms of Failure

Let’s delve deeper into the function of each major car engine part and explore the common symptoms that indicate potential issues. Understanding these symptoms can help you identify problems early and prevent more significant damage.

The core components that constitute your car’s engine include: the engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valve train, valves, rocker arms, pushrods/lifters, fuel injectors, and spark plugs.

#1. The Engine Block (Cylinder Block)

The engine block, also known as the cylinder block, is the foundational structure of the engine. It serves as the housing for all the major internal engine parts, forming the lower section of the engine.

The crankshaft rotates within the engine block, and the pistons move up and down inside the cylinder bores, driven by the force of fuel combustion. In some engine designs, the cylinder block also provides housing for the camshaft.

Modern engine blocks are typically constructed from aluminum, while older vehicles often used cast iron. Aluminum offers lighter weight, while cast iron provides durability and was traditionally used for its strength. The metallic construction of the engine block is crucial for its structural integrity and efficient heat transfer from the combustion process to the integrated cooling system.

The engine block is characterized by numerous precisely machined holes and passages. These accommodate the cylinders, as well as create pathways for the circulation of water and oil, essential for engine cooling and lubrication. Water flow paths are generally wider than oil paths to facilitate efficient heat dissipation.

These intentionally designed paths maintain optimal engine temperature and ensure that all moving parts are adequately lubricated, minimizing friction and wear.

When the cylinder head is securely attached to the top of the engine block, it encloses the cylinders, creating combustion chambers. The pistons move within these cylinders, driving the crankshaft’s rotation, which ultimately powers the wheels.

The oil pan is positioned at the base of the engine block, acting as an oil reservoir. The oil pump draws oil from the pan and circulates it through the engine’s oil passages, lubricating the moving parts.

Common Symptoms of a Failing Engine Block:

- Reduced engine performance due to low engine compression.

- Visible engine smoke, indicating potential internal leaks or combustion issues.

- Engine overheating, often caused by antifreeze leaks from cracks in the block.

- Discoloration in engine oil or antifreeze, suggesting contamination or mixing of fluids.

- Oil or coolant leaks externally from the engine block.

- Frozen coolant in the radiator, which can crack the engine block in cold weather.

- Excessive smoke from the exhaust, which can be a sign of coolant or oil burning inside the cylinders.

- Low coolant levels, indicating a leak that might be internal or external, potentially from the block itself.

#2. The Piston

Pistons are critical moving components within your car engine. Their primary function is to convert the pressure generated by the burning air-fuel mixture into a linear force that acts upon the crankshaft.

The design and shape of a piston are largely determined by the type of internal combustion engine. Gasoline engine pistons are typically lighter and shorter compared to pistons used in diesel engines, which require greater strength to withstand higher compression ratios.

Each piston is connected to the crankshaft via a connecting rod. The connection between the piston and connecting rod is facilitated by a hollow tube called a wrist pin or gudgeon pin. This piston pin must withstand the intense forces of combustion. Collectively, the piston, connecting rod, and wrist pin are known as the piston assembly.

The small gap between the piston and the cylinder wall is sealed by piston rings, which fit into grooves on the piston band. The areas between these grooves are termed ring lands.

Pistons move up and down within the cylinder twice for every crankshaft revolution. In engines operating at 1300 rpm, pistons can move up and down 2600 times per minute, highlighting the rapid and repetitive motion they endure.

Key Functions Performed by the Piston:

- Heat Dissipation: Pistons contribute to dissipating the intense heat generated during combustion, helping to regulate engine temperature.

- Combustion Chamber Sealing: They ensure a tight seal of the combustion chamber, preventing gas leakage and oil from entering the combustion area.

- Connecting Rod Guidance: Pistons guide the movement of the connecting rod, ensuring efficient power transfer.

- Continuous Gas Exchange: They facilitate continuous gas exchange within the combustion chamber, enabling the intake of fresh air-fuel mixture and exhaust of combustion gases.

- Variable Volume Creation: Pistons create the variable volume within the combustion chamber, essential for the compression and expansion strokes.

Common Symptoms of Bad Pistons:

- White or gray exhaust smoke, indicating oil burning within the cylinders.

- Excessive oil consumption, as oil leaks past worn or damaged piston rings.

- Reduced power during acceleration, due to poor compression and inefficient combustion.

- Overall loss of power or poor engine performance, stemming from compromised combustion.

#3. The Crankshaft

The crankshaft is often considered the backbone of the internal combustion engine. It’s responsible for the fundamental operation of the engine, specifically the conversion of linear motion into rotary motion.

It captures the linear energy from the pistons’ up-and-down movements and transforms it into the rotational energy that ultimately drives your car’s wheels. The crankshaft is situated within the crankcase, which is located below the engine block.

Crankshafts are typically manufactured from steel due to its high strength and durability. Steel’s robustness is essential to withstand the continuous stresses and rotational forces.

Crankshafts are generally designed as single-piece components for added strength and reduced stress points under heavy loads and oscillations. This single-piece construction is crucial given the high rotational speeds and forces crankshafts endure.

The crankshaft is supported at both ends by large bearings within the engine block. It connects to the flywheel and subsequently to the clutch.

When the clutch is engaged, the crankshaft’s rotational energy is transmitted through the gearbox and then through the differential to the drive shafts that connect to the wheels, enabling the vehicle’s movement.

Symptoms of a Bad or Failing Crankshaft Position Sensor (often mistaken for crankshaft issues):

- Difficulty starting the vehicle or no-start conditions.

- Intermittent stalling while driving.

- Check Engine Light illumination on the dashboard.

- Uneven acceleration or hesitation.

- Engine misfires or vibrations, indicating irregular combustion.

- Rough idle and/or vibrating engine at rest.

- Reduced fuel efficiency, as the engine may not be running optimally.

#4. The Camshaft

A camshaft is a relatively simple yet critical engine component. It’s essentially a rod or shaft with shaped cams, also known as “cam lobes,” positioned along its length.

As the shaft rotates, the cam lobes interact with valves or other components, controlling their movement in proportion to the cam’s shape. The rotation speed of the camshaft dictates the speed of these actions.

In modern internal combustion engines, camshafts are commonly located directly above the cylinder banks, where they directly control the valves.

Their precise calibration governs the timing and duration of valve opening and closing, regulating the amount of air-fuel mixture entering the combustion chamber and the efficient expulsion of exhaust gases.

This precise control makes the camshaft crucial for engine operation and performance. By opening and closing the engine’s inlet and exhaust valves at the correct times, the camshaft profoundly influences engine efficiency and power output.

To ensure accurate timing, camshafts are connected to the crankshaft’s rotation via a timing belt or chain. This synchronization ensures that valve operation is precisely coordinated with piston movement. Furthermore, the shape of the cam lobes is carefully engineered to control the rate at which valves open and close, optimizing engine performance across different speeds and loads.

Like other critical engine parts, camshafts are made from robust metals like chilled iron, which offers superior strength and wear resistance.

Symptoms of a Bad Camshaft:

- Active or flashing Check Engine Light, indicating a detected camshaft issue.

- Loss of engine power, especially noticeable during acceleration.

- Steady popping or backfiring in the intake manifold or exhaust, often indicating extreme cam wear.

- Loud ticking or tapping sounds emanating from the engine, potentially from worn cam lobes or lifters.

- Metal debris in the engine oil, a sign of camshaft wear or damage.

- Cylinder misfires, due to improper valve timing or operation.

- Increased emissions due to misfiring and inefficient combustion.

- Visible signs of damage upon inspection, such as worn or damaged cam lobes.

#5. The Connecting Rod

As its name suggests, a connecting rod is a critical link that connects the piston to the crankshaft. These rods are typically made of either steel or aluminum, chosen for their strength and durability.

A connecting rod, often called a ‘con rod,’ is a fundamental engine part that bridges the piston and crankshaft, enabling the transfer of power.

The connecting rod, working in conjunction with the crank, converts the piston’s linear, reciprocating motion into the crankshaft’s rotational motion.

The end of the connecting rod that attaches to the piston is known as the small end, while the end that encircles the crankshaft is called the big end. The big end incorporates bearing inserts to minimize friction and maintain precise oil clearance with the connecting rod journal on the crankshaft.

The connecting rod is split into two parts, with a connecting rod cap used to securely clamp the connecting rod bearing around the crankshaft journal.

The connecting rod’s primary function is to transmit both compressive and tensile forces from the piston to the crankshaft. In internal combustion engines, it’s designed to pivot at the piston end and rotate at the crankshaft end, accommodating the complex motion.

Many connecting rods feature a drilled oil passage extending from the big end up through the rod to an outlet hole along its length. This passage allows oil to flow up the connecting rod and spray onto the cylinder wall, providing crucial lubrication in the area of highest pressure and friction.

Symptoms of a Bad Connecting Rod:

- Low compression in one or more cylinders, as a bent rod can affect piston travel.

- Engine knocking sounds (Rod Knock), a distinct and serious knocking noise indicating bearing failure or rod damage.

- Low oil level or oil pressure, possibly due to damage affecting lubrication.

- Visibly bent or damaged rod upon engine inspection.

- Seized engine, in severe cases where a rod breaks and causes catastrophic engine damage.

#6. Timing Belts

The timing belt is an indispensable component within your vehicle’s engine. It ensures that various moving parts operate in precise synchronicity for optimal engine efficiency and performance.

The timing belt orchestrates the engine’s combustion cycle by connecting the crankshaft and camshaft.

As the crankshaft rotates with piston movement, the timing belt drives the camshaft, which controls the intake and exhaust valves. This precise coordination ensures that pistons and valves operate harmoniously, preventing collisions and maximizing engine efficiency.

Modern timing belts are constructed from robust synthetic rubbers like neoprene, polyurethane, or highly saturated nitrile, reinforced with high-tensile cords made of Kevlar, polyester, or fiberglass. These materials provide strength and flexibility to withstand engine stresses.

However, timing belts can wear over time due to temperature fluctuations and continuous use. It’s generally recommended to replace a vehicle’s timing belt every 60,000 to 100,000 miles as preventative maintenance.

When a timing belt becomes worn, it may begin to slip, leading to severe engine misfires. Unfortunately, timing belt failure often occurs suddenly without gradual warning signs. When a timing belt fails, it’s typically an abrupt event, causing the engine to stop immediately or lose significant power.

Symptoms of a Failing Timing Belt:

- A ticking noise coming from the engine, potentially indicating belt wear or tensioner issues.

- The engine won’t turn over or cranks but doesn’t start, due to disrupted timing.

- The engine acts up between 2,000 – 4,000 RPM, showing performance issues at mid-range speeds.

- The engine misfires, as valve timing is compromised.

- More smoke and fumes than normal from the exhaust, due to incomplete combustion.

- Oil leaks from the front of the motor, potentially from timing cover seals damaged by belt failure.

#7. Spark Plugs

Spark plugs are located above each cylinder in gasoline engines. As their name suggests, spark plugs are responsible for igniting the air-fuel mixture within the engine cylinders, initiating the combustion process.

The purpose of a spark plug is to convert high-voltage electricity, generated by an ignition coil in modern engines, into a spark. This spark is precisely timed to occur within the combustion chamber just before the power stroke, igniting the compressed air-fuel mixture.

A spark plug consists of a threaded metal sleeve electrically insulated from a central electrode by a ceramic insulator. The center electrode, which may contain a resistor, is connected to the output terminal of an ignition coil or magneto via a heavily insulated wire.

The metal housing of the spark plug is screwed into the cylinder head and is electrically grounded.

The center electrode extends through the porcelain insulator into the combustion chamber, forming one or more spark gaps between its inner end and projections or structures attached to the threaded jacket, called the side earth or ground electrode.

Spark plugs can degrade in performance over time due to wear, carbon buildup, or issues within the electrical/ignition system.

They can become “fouled” by combustion byproducts, contamination, or overheating, losing their ability to effectively ignite the air-fuel mixture and dissipate heat from the combustion chamber.

Symptoms of Bad Spark Plugs:

- Reduced gas mileage, as inefficient combustion wastes fuel.

- Lack of acceleration or sluggish engine response.

- Hard starts or difficulty starting the engine.

- Engine misfires, causing rough idling and power loss.

- Rough idling, with noticeable engine vibrations.

#8. Cylinder Head

A cylinder head sits atop the engine block, sealing the cylinder and forming the combustion chamber.

Cylinder heads must be exceptionally robust to withstand immense pressures and high temperatures during combustion, while maintaining their shape to seal effectively against the cylinder block using a head gasket. They are crucial for controlling both airflow into and out of the cylinders, as well as fuel delivery.

The cylinder head integrates numerous essential components, including intake and exhaust ports, coolant passages, valves, camshafts (in overhead cam engines), spark plugs, and fuel injectors.

Cast iron cylinder heads are known for their durability and lower manufacturing cost. However, cast iron is heavier and less efficient at dissipating heat. For this reason, many manufacturers prefer aluminum cylinder heads.

Aluminum cylinder heads are significantly lighter than cast iron, improving vehicle weight distribution and heat dissipation. High-performance and racing cars commonly utilize aluminum cylinder heads for their performance advantages.

The most common cause of cylinder head failure is overheating, often triggered by coolant loss, head gasket failure, or restricted coolant flow.

In severe cases, a cracked or damaged cylinder head can lead to irreparable damage to the entire engine. Addressing cylinder head issues promptly is crucial to prevent catastrophic engine damage.

Symptoms of a Cracked Cylinder Head:

- White smoke (steam) from the exhaust pipe, indicating coolant burning in the cylinders.

- Low coolant level, with no visible external leaks.

- Engine overheating, often rapidly and repeatedly.

- Rough running and misfiring, due to coolant entering the cylinders and disrupting combustion.

- Combustion gases in the cooling system, indicated by bubbles in the coolant reservoir or radiator.

- Illuminated warning lights on the dashboard, such as the Check Engine Light or temperature warning.

- Coolant-oil intermix, creating a milky or frothy appearance in either the coolant or engine oil.

#9. The Oil Pan

With numerous metal parts in constant motion within a car engine, lubrication is essential for smooth operation and longevity. Engine oil plays this crucial role.

The oil pan is bolted to the underside of the engine and serves as the reservoir for engine oil. This oil is pumped throughout the engine to lubricate, clean, and cool moving components.

An oil pump draws oil from the pan and forces it through an oil filter to remove dirt and debris before circulating it through the engine’s oil passages.

After circulating through the engine, the oil returns to the oil pan, and the lubrication cycle begins anew. Regular engine oil checks are vital, as the engine’s proper function depends heavily on adequate oil levels and quality.

The oil pan is typically made of steel or aluminum and can hold four to six liters of oil, depending on the engine size. The oil dipstick extends into the oil pan, allowing you to measure the oil level. A drain plug at the bottom of the pan can be removed to drain the oil during oil changes.

Symptoms of a Bad Oil Pan:

- The low oil warning light illuminates on the dashboard.

- You see a puddle of oil under your car, indicating an external oil leak.

- Your oil level has dropped unexpectedly, requiring frequent oil top-offs.

- Your engine is overheating, as insufficient oil can lead to increased friction and heat.

- You notice a burning smell coming from the engine, possibly from oil leaking onto hot engine parts.

#10. Engine Valves

Engine valves are mechanical components used in internal combustion engines to precisely control the flow of fluid or gas to and from the combustion chambers or cylinders during engine operation.

Functionally, engine valves are similar to other types of valves in that they block or redirect flow. However, they are purely mechanical devices, interacting with engine components like rocker arms to open and close in a precisely timed sequence.

Intake valves regulate the flow of air and fuel mixture into the combustion chamber. Exhaust valves control the expulsion of exhaust gases produced after combustion.

Valve movements are controlled by pear-shaped lobes, called cams, on a rotating camshaft. The camshaft is driven by a chain, belt, or gears connected to the crankshaft, ensuring synchronized valve timing.

In engines where the camshaft is mounted within the engine block, small metal cylinder tappets sit in channels above each cam. A metal pushrod extends upward from the tappets into the cylinder head.

The top of each pushrod interacts with a rocker arm, which presses against the stem of a valve. The valve is held in a raised (closed) position by a strong coil spring, known as the valve spring.

As the pushrod rises on the cam lobe, it pivots the rocker arm, which pushes the valve downwards (open) against the pressure of its spring. As the cam continues to rotate, the valve spring force closes the valve. This is called an overhead valve (OHV) system.

Some engines employ an overhead camshaft (OHC) system, eliminating pushrods. In these designs, valves are actuated more directly by single or dual camshafts located within the cylinder head itself.

Symptoms of Bad Valves:

- Poor cold engine performance, as valve sealing may be compromised when cold.

- Off-throttle braking, due to reduced engine braking from leaking valves.

- Rough idling, as improper valve sealing affects cylinder balance.

- Excessive oil consumption, if valve stem seals are worn or valves are leaking oil into the combustion chamber.

- Excessive smoke from the exhaust, potentially blue (oil burning) or black (rich fuel mixture).

- Loss of engine power, due to reduced compression and inefficient combustion.

#11. Combustion Chamber

A combustion chamber is the enclosed space within the cylinder where the fuel/air mixture is burned. It’s essentially a sealed cylinder formed by the cylinder head and piston.

The primary function of the combustion chamber is to facilitate the controlled burning of the air-fuel mixture, producing high-pressure and high-temperature gases.

The piston compresses the fuel/air mixture, and the spark plug ignites it. The resulting combustion generates energy, pushing the piston and initiating the power stroke. This energy release is captured and used to power the engine.

The actual size of the combustion chamber is defined as the volume above the piston when it’s at Top Dead Center (TDC) with both intake and exhaust valves closed.

A smaller combustion chamber volume results in a higher compression ratio, which generally leads to increased engine power. However, higher compression also generates higher combustion temperatures.

The size of the combustion chamber can be adjusted by modifying the cylinder head design or changing the shape of the piston head.

What happens if oil gets into the combustion chamber? Oil burning within the combustion chamber results in blue-grey-colored exhaust gases. Oil can enter the chamber past worn valve stem seals or piston rings. Worn valve seals can allow oil to seep into the cylinders overnight, leading to blue-tinted exhaust smoke, especially upon morning startup.

#12. Intake Manifold

The intake manifold is a crucial component that distributes air to the engine’s cylinders. In many cars, it also serves as the mounting point for fuel injectors.

The manifold directs air into the combustion chamber during the intake stroke. This air is then mixed with fuel from the injector, initiating the combustion cycle.

Air reaches the intake manifold after passing through the air cleaner assembly, which houses the car’s air filter.

The intake manifold comprises two main parts: the plenum and the runners. The plenum is the chamber that receives air from the throttle body, while the runners are individual tubes that distribute air to each cylinder.

Engine performance can be fine-tuned by adjusting the size of the intake plenum and the length or diameter of the runners. Modern cars often incorporate variable intake manifolds to optimize airflow across different engine speeds and loads.

Intake manifold problems are relatively infrequent, but some diesel car models utilize swirl flaps within the intake ports. These flaps are designed to enhance airflow at lower engine speeds. However, they can become fouled by exhaust gas recirculation (EGR) deposits, leading to sticking or breakage. Broken swirl flaps can be sucked into the engine cylinders, causing significant damage.

The cost of intake manifold replacement varies based on car engine and model, and whether original equipment manufacturer (OEM) or aftermarket parts are used.

Symptoms Of A Bad Intake Manifold:

- Check Engine Light illumination on the dashboard.

- Engine misfires, due to uneven air distribution or vacuum leaks.

- Rough idle, as air leaks disrupt smooth engine operation.

- Loss in engine performance, particularly at higher RPMs.

- External coolant leaks, if the intake manifold incorporates coolant passages and gaskets fail.

- Engine Overheating, in cases of significant coolant leaks from the intake manifold.

#13. Exhaust Manifold

In an engine, an exhaust manifold collects exhaust gases from multiple cylinders and channels them into a single exhaust pipe. It features multiple ports, one for each cylinder, and is attached to the cylinder heads with gaskets.

As the first component of the exhaust system, the exhaust manifold gathers the hot exhaust gases exiting the engine cylinders and directs them towards the catalytic converter for emissions treatment.

In turbocharged engines, the turbocharger is typically positioned downstream of the exhaust manifold, utilizing the exhaust gas energy to spin its turbine. Exhaust manifolds are commonly constructed from tubular steel, stainless steel, or cast iron, chosen for their heat resistance and durability.

The exhaust manifold not only collects burned exhaust gases but also facilitates further combustion of any unburned or partially burned gases due to its high operating temperature. The manifold also houses the oxygen sensor, which monitors the oxygen content in the exhaust stream.

The oxygen sensor provides feedback to the engine control unit (ECU), allowing it to adjust the air-fuel mixture for optimal combustion efficiency and emissions control.

Leaks in the exhaust manifold or its gasket can allow exhaust gases to escape, posing a health hazard to vehicle occupants due to carbon monoxide exposure. Exhaust leaks can also disrupt oxygen sensor readings, triggering a Check Engine Light. Larger manifold leaks can produce a noticeably loud exhaust noise.

Symptoms of a Cracked or Bad Exhaust Manifold:

- Check Engine Light illumination, often due to oxygen sensor readings being affected by exhaust leaks.

- Burning smells inside the vehicle, from escaping hot exhaust gases.

- Performance problems or sluggish acceleration, due to reduced engine efficiency.

- Poor fuel economy, as the engine may run less efficiently due to exhaust leaks.

- Loud exhaust noise, especially noticeable during acceleration.

- Visible damage to the exhaust manifold upon inspection, such as cracks or rust.

#14. Piston Ring

A piston ring is a metallic split ring that fits into a groove on the outer diameter of a piston in an internal combustion engine.

Piston rings are typically made of cast iron due to its wear resistance and ability to maintain sealing under high temperatures and pressures.

The sliding motion of the piston ring against the cylinder wall generates friction, which accounts for approximately 24% of the total mechanical frictional losses within an engine.

Piston rings perform four primary functions: compression gas sealing, oil control, heat transfer, and wear control.

- Compression Gas Sealing: Piston rings provide an effective gas seal between the piston and cylinder wall, maintaining compression within the combustion chamber.

- Oil Control: They regulate the amount of oil on the cylinder wall, preventing excessive oil from entering the combustion chamber and minimizing oil consumption and harmful emissions.

- Heat Transfer: Piston rings facilitate heat transfer from the hot piston to the cooled cylinder block, preventing heat buildup in the piston and potential damage.

- Wear Control: They contribute to wear control by distributing wear across the cylinder wall and piston ring surfaces, extending engine component life.

Car engines typically use three piston rings per cylinder. The two upper rings, known as compression rings, primarily seal the combustion chamber. The lower ring, called the oil scraper ring, regulates oil consumption.

Symptoms of Bad Piston Rings:

- Discolored or excessive exhaust smoke, often blueish, indicating oil burning.

- Oil leaks or profuse oil consumption, as oil bypasses worn rings.

- Declining engine performance, due to reduced compression and power.

- Low acceleration, as cylinder pressure is compromised.

- Oil in the intake manifold, indicating blow-by past the piston rings.

#15. Gudgeon Pin (Wrist Pin)

A gudgeon pin, also known as a wrist pin in the US, is a crucial component in an internal combustion engine that connects the piston to the connecting rod. It provides a bearing surface around which the connecting rod can pivot as the piston moves.

The piston pin is typically a forged, short, hollow rod made of high-strength, hardened alloy steel. It may be designed to float freely within both the connecting rod and piston or be press-fit into one of these components.

The ends of the pin are chamfered to facilitate assembly and reduce stress concentration. It’s secured within the piston, and the small-bore end of the connecting rod pivots around it.

#16. Cam

A cam is a rotating or sliding component in a mechanical linkage used to convert rotary motion into linear motion.

In an engine, the camshaft is a shaft with multiple cams attached. These cams convert the camshaft’s rotary motion into the linear motion needed to operate engine valves. Cams are responsible for precisely controlling the opening and closing timing of the valves.

The shape of the cams significantly influences engine characteristics and performance. As the camshaft rotates, the cam’s shape dictates the extent to which it acts upon a valve or switch.

If a cam is worn or damaged, it can disrupt the precise timing of the air-fuel mixture entering and exiting the combustion chambers, leading to performance issues.

#17. Flywheel

A flywheel is a heavy wheel attached to the end of the crankshaft that rotates with it. It’s typically made from cast iron and steel for its mass and durability.

The primary function of the flywheel is to smooth out the pulses of energy generated during the engine’s combustion process. It stores rotational energy and releases it to maintain crankshaft rotation between power strokes, reducing engine vibration.

It also provides momentum for the compression stroke of the pistons, making the engine easier to rotate and start.

The flywheel helps counterbalance the engine and promotes smooth crankshaft rotation by reducing vibration and noise generated during combustion.

Additionally, the flywheel assists in engine starting by providing the initial rotational inertia needed for the engine to overcome compression and begin running. Without a flywheel, most car engines would be difficult to start and would run very roughly.

Symptoms of a Bad Flywheel:

- Slipping gears, as a worn flywheel can affect clutch engagement.

- Difficulty changing gears or grinding noises during gear shifts.

- Burning odor, from clutch slippage due to flywheel issues.

- Vibrations of the clutch (Clutch Chatter), felt through the clutch pedal.

- Unable to start, or inconsistent starts, if the flywheel’s starter ring gear is damaged.

- Engine stalling, due to uneven crankshaft rotation.

- Engine vibrations with clutch engaged, indicating flywheel imbalance.

#18. Head Gasket

The head gasket is a crucial sealing component in a car engine. It creates a seal between the engine block and the cylinder head(s). A car engine is fundamentally divided into the engine block, which houses the pistons and cylinders, and the cylinder head, which contains valves, spark plugs, etc.

The primary function of the head gasket is to seal the combustion gases within the cylinders, preventing leaks and maintaining cylinder pressure. It also prevents coolant or engine oil from leaking into the cylinders or mixing with each other. Head gasket leaks can lead to significant engine performance problems.

To enhance durability and longevity, most manufacturers use thin layers of steel in head gasket construction. As a critical sealing element, the head gasket plays a vital role in engine integrity, similar to the role of the skeleton in a car body.

With engine downsizing trends in modern cars, head gaskets are also being designed to be lighter and stiffer to meet new engine demands.

Signs Your Head Gasket Is Blown:

- Engine Overheating, often rapid and unexplained.

- White smoke from the tailpipe, indicating coolant burning in the combustion chamber.

- Low coolant level, with no visible external leaks.

- Rough idle/Engine knock, due to coolant entering cylinders or compression loss.

- Contaminated engine oil, appearing milky or frothy due to coolant mixing with oil.

#19. Cylinder Liner (Cylinder Sleeve)

A cylinder liner, also known as a cylinder sleeve, is a thin-walled, hard-metal cylinder inserted into an engine’s cylinder block. The piston moves up and down within this liner.

The liner becomes an integral part of engine operation, providing the sliding surface for the piston and protecting the engine block from wear, heat, and contamination.

Cylinder liners are typically made of cast iron alloyed with nickel, chromium, molybdenum, vanadium, or other elements to enhance wear resistance and oil retention.

They are centrifugally cast and must possess good wear resistance and the ability to retain oil for lubrication between the liner walls and piston rings. Cylinder liners are designed to be removable and replaceable when worn.

There are three basic types of cylinder liners: hot, dry, and wet.

- Hot cylinder liners are used in air-cooled engines and are made of heat-resistant materials similar to dry liners.

- Dry cylinder liners are used in water-cooled engines and are relatively thinner than wet liners due to their simpler design and heat transfer through the engine block.

- Wet cylinder liners are in direct contact with the engine coolant. They help dissipate heat more effectively and may have small openings for coolant circulation. Wet liners offer low lubricating oil consumption and excellent heat conduction.

Regular inspection of cylinder liners is crucial. Check for cracks, fretting, or scoring. Cracks, seizures, or scoring necessitate cylinder replacement. Cavitation erosion, caused by cooling system issues, should also be inspected.

Metal filings, nicks, burrs, or improper fillets can compromise liner fit. Dents on the cylinder and piston rings often indicate liner damage. Low piston ring or compression pressure and rapid piston ring wear are signs of cylinder scoring.

#20. Crankcase

The crankcase is the central structural component of the engine. It houses the entire crank mechanism, including the piston, cylinders, and connecting rods.

Accessories, the gearbox/transmission, and the cylinder head are attached to the crankcase, making it a foundational element of the engine assembly.

Due to the oil and coolant channels required for cooling and lubrication, the crankcase is often the most complex casting in an internal combustion engine.

An open crank engine design lacks a crankcase. This design was used in early engines and is still employed in some large marine diesel engines.

The crankcase forms the central engine component, housing the drive mechanism and cooling jacket.

Crankcase pressure readings can provide diagnostic information about the PCV (Positive Crankcase Ventilation) system and the overall engine condition.

#21. Engine Distributor

An engine distributor is an ignition system component that distributes high-voltage sparks to each of the engine’s spark plugs in the correct firing order and timing.

Voltage from the ignition coil is routed to the distributor cap via a spark plug wire. This voltage travels from the center terminal of the cap to the rotor inside the distributor.

As the distributor shaft rotates, the rotor also rotates, sequentially distributing voltage to each of the outer terminals of the cap.

The voltage then travels from each outer terminal through individual spark plug wires to each spark plug. The spark plugs fire, igniting the air-fuel mixture in the engine cylinders.

A failing ignition distributor can cause engine misfires or a complete no-start condition. Failure can occur abruptly, leading to engine stalling or preventing a cold engine from starting.

Sometimes, issues become apparent before complete failure. Engine shaking at idle or a high-pitched squeak from under the hood may indicate distributor problems.

Symptoms of a Bad Engine Distributor:

- Your car won’t start or cranks but fails to ignite.

- Your engine keeps misfiring or backfiring, due to erratic spark delivery.

- Your car is shaking or running roughly, especially at idle.

- Your Check Engine Light comes on, indicating ignition system faults.

- You hear a high-pitched noise (squealing or whining) from under the hood, potentially from distributor bearings.

- You failed your last emissions test, as misfires increase emissions.

#22. Distributor O-ring

The distributor o-ring is typically a small, round rubber seal. While seemingly insignificant, it plays a crucial role in distributor function.

The distributor’s precise timing is essential for accurate spark plug firing. If the distributor shifts out of alignment, it can cause significant timing issues and potential engine damage.

The distributor O-ring seals the distributor housing to the engine block, preventing oil leaks, engine misfires, and loss of power. O-ring failure can lead to oil leaks at the base of the manifold, causing further complications.

Over time, the O-ring can degrade due to:

- Exposure to engine heat and internal elements.

- Electrical discharge and heat.

- Accumulation of dirt and debris.

If the distributor o-ring leaks, oil and dirt will accumulate around the distributor base. Regular vehicle servicing and tune-ups (around every 30,000 miles) can help prevent O-ring failure. Mechanics typically inspect the distributor housing during tune-ups to check for leaks or signs of wear and replace the O-ring as needed.

Symptoms of a Bad or Failing Distributor O-ring:

- Oil leaking from the base of the distributor, a visible sign of seal failure.

- Lack of power, due to timing inaccuracies caused by distributor movement.

- The engine running rough, as timing errors disrupt combustion.

- Engine misfire, from inconsistent spark delivery.

#23. Cylinder Headcover

A cylinder head cover seals the top of the cylinder head. It’s typically made from cast iron or aluminum alloy. Aluminum alloy is often preferred for its lighter weight and superior heat dissipation.

The cylinder head cover encloses the combustion chamber area, providing a sealed space for internal combustion to occur.

During engine operation, blow-by gases from combustion and oil droplets from the lubrication system are present inside the cylinder head. The cylinder head cover helps contain these elements.

The cylinder head is located atop the engine block and houses components such as intake and exhaust valves, valve springs and lifters, and the combustion chamber. The cylinder head cover provides a protective and sealing top surface for these components.

#24. Rubber Grommet

An automotive grommet is a small, round rubber component inserted into a drilled hole in an engine body or other vehicle part. It serves multiple purposes:

- Protection of electrical wires, tubes, or hoses: Grommets cushion and protect these components from abrasion against sharp edges of the hole.

- Water ingress prevention: Grommets create a seal, preventing water and debris from entering through the hole.

Grommets are essential wiring accessories.

They are specifically designed for wires passing through holes in metal panels. Their primary functions are to protect wires from being cut or chafed by sharp sheet metal edges and to provide dust and water resistance.

#25. Oil Filter

The oil filter is a critical component that removes contaminants from your car’s engine oil. Over time, engine oil accumulates wear particles and combustion byproducts that can harm engine components.

Clean engine oil is essential for lubrication and engine longevity. Unfiltered oil becomes saturated with hard, abrasive particles that accelerate wear on engine surfaces.

The oil filter typically consists of a metal canister with a gasket for sealing against the engine mating surface.

The base plate of the canister holds the gasket and features perimeter holes for dirty oil entry. A central hole is threaded to connect to the oil filter assembly on the engine block. The canister contains filter media, usually made of synthetic fiber.

The engine’s oil pump forces oil through the filter. Dirty oil enters through the perimeter holes, is pushed through the filter media under pressure, and clean oil exits through the central hole, re-entering the engine’s lubrication system.

Many manufacturers recommend replacing the oil filter at every second oil change. For example, on a 3,000-mile oil change cycle, replace the filter every 6,000 miles. On a 6,000-mile cycle (common for modern vehicles), replace the filter every 12,000 miles.

#26. Camshaft Pulley

A camshaft pulley is a component in the engine’s timing system. It controls the rotational speed of the camshaft, which in turn governs the operation of the poppet valves (intake and exhaust valves).

The camshaft pulley is connected to the timing belt or timing chain, synchronizing camshaft rotation with crankshaft rotation.

Camshaft pulleys are located at the front of the engine, at the end of each camshaft. The timing belt or chain runs around these pulleys and the crankshaft pulley, ensuring accurate engine timing. Damage or failure of camshaft pulleys can lead to timing belt/chain failure and severe engine damage.

#27. Timing Belt Drive Pulley

Timing pulleys are used to connect and synchronize rotation between two shaft systems.

In engines, a timing belt pulley system connects the camshaft and crankshaft, ensuring precise valve timing relative to piston position.

The pulley’s sprocket body is lined with teeth that mesh with the timing belt, preventing slippage and maintaining accurate synchronization.

Timing pulleys feature teeth or pockets around their outer diameter. These teeth or pockets engage with corresponding features on the timing belt (holes or drive lugs), ensuring precise timing and power transmission.

Symptoms Of a Bad Timing Belt Pulley:

- Shaky or erratic belt motion, visible during inspection.

- Visible wear on the pulleys, such as damaged teeth or grooves.

- Belt “squealing” or “whining” noises, indicating belt slippage or pulley misalignment.

- Knocking or slapping noises from the timing belt area, suggesting pulley issues.

- Damaged bearings or pulleys, detectable as play or roughness in pulley rotation.

#28. Water Pump

A water pump is a critical component of your car’s cooling system.

Its primary function is to continuously circulate coolant (a mixture of water and antifreeze) from the radiator to the engine block, preventing engine overheating.

Modern water pumps are designed for durability, but they can still fail after extended use or high mileage.

The water pump is typically driven by a belt connected to the crankshaft pulley or sprocket.

A car’s water pump uses impeller blades and centrifugal force to propel coolant through the engine’s cooling channels and hoses.

After circulating through the engine, hot coolant is routed through hoses to the radiator, typically located at the front of the car. Airflow across the radiator fins cools the hot coolant. The cooled coolant then returns to the water pump to begin the circulation process again.

Common Causes of Water Pump Failure:

- Contaminated coolant: Debris and contaminants in the coolant can damage the pump’s seals and bearings.

- Mixed coolant types: Using incompatible coolant types can lead to corrosion and pump damage.

- Cavitation: Air bubbles or vapor cavities in the coolant can implode within the pump, causing erosion and damage to pump components.

Symptoms of a Failing Water Pump in Your Car:

- Leaking coolant, visible as puddles under the car, often near the front.

- Overheating engine, as coolant circulation is impaired.

- Coolant leaks into the oil, resulting in milky or frothy oil.

- Engine noise (whining, grinding, or knocking) from the water pump area, indicating bearing failure.

#29. Turbocharger and Supercharger

“Supercharging” and “turbocharging” are forced induction methods used to increase engine power output by compressing the air entering the engine.

Compressed air allows more fuel to be burned per combustion cycle, resulting in greater power. The main difference between turbochargers and superchargers lies in their power source.

A turbocharger utilizes the energy of hot exhaust gases exiting the engine cylinders. These gases drive a turbine, which in turn spins a compressor (impeller). The compressor then forces more air into the engine intake.

A supercharger also compresses intake air but is mechanically driven by the engine itself, typically via a belt connected to the crankshaft or an electric motor.

Turbochargers are advantageous for boosting power, especially in smaller engines. They offer significant power gains, and boost levels can be adjusted.

Superchargers deliver power directly from the engine, eliminating turbo lag (the delay in power delivery often associated with turbochargers). Supercharger systems are generally simpler than turbocharged systems.

Symptoms of a Damaged or Failing Turbocharger:

- Loss of power and reduced engine performance.

- Slower, louder acceleration, with noticeable turbo lag.

- Difficulty maintaining high speeds, indicating insufficient boost.

- Blue/grey smoke coming from the exhaust, suggesting oil leaks into the turbocharger.

- The engine dashboard light is showing (Check Engine Light), indicating turbocharger system faults.

Symptoms of a Bad Supercharger:

- Ticking sound coming from the motor, potentially from supercharger components.

- Decreased fuel efficiency, as the supercharger consumes engine power.

- Immediate loss of power, if the supercharger malfunctions.

#30. Oil Pan Drain Bolt (Oil Pan Drain Plug)

The oil pan drain bolt, also called the oil pan drain plug, is a threaded metal bolt located at the bottom of the oil pan.

When removed, it allows engine oil to be drained from the oil pan during oil changes.

Positioned at the bottom or side of the oil pan, the drain plug is designed to prevent oil leakage due to gravity and crankcase pressure.

During engine oil changes, the oil pan drain plug is removed to drain the old oil. If oil leaks are noticed around the oil pan bolt, replacing the bolt gasket or washer is often a simple fix.

Signs that your oil drain plug is worn out and needs replacing:

- A puddle of engine oil under your car, directly beneath the oil pan area.

- Visible damage to the drain plug, such as stripped threads or cracks.

- Dropping oil level between oil changes, indicating a slow leak.

- Engine performance problems, in severe cases of oil loss and low oil pressure.

#31. The Valvetrain

The valvetrain is the system of components that controls the movement of engine valves.

It includes the valves themselves, along with pushrods, lifters, and rocker arms (in certain engine designs). The valvetrain is located within the cylinder head and engine block and is crucial for proper valve operation and timing.

#32. The Rocker Arms

Rocker arms are part of the valvetrain system, used in engines with overhead valves (OHV).

Rocker arms work in conjunction with cams (on the camshaft) to actuate the valves. As the camshaft rotates, the cams push on the rocker arms, which in turn press down on the valve stems, opening the valves to allow air intake or exhaust gas expulsion.

#33. The Pushrods/Lifters

In overhead valve (OHV) engines where the camshaft is located in the engine block, pushrods and lifters are essential valvetrain components.

Pushrods are rods that transmit motion from the camshaft lifters (which ride on the cam lobes) to the rocker arms in the cylinder head. Lifters are positioned between the camshaft and pushrods, translating the camshaft’s rotary motion into linear motion to actuate the pushrods and valves.

#34. Throttle Body

The throttle body is responsible for regulating the amount of air entering the engine’s intake manifold.

By controlling the size of the throttle valve opening within the throttle body, it directly dictates the engine’s airflow, power output, and RPMs, based on the driver’s accelerator pedal input.

#35. The Fuel Injectors

Fuel injectors are critical components in modern engines that deliver fuel into the combustion chambers.

For the combustion process to occur, precise fuel delivery is essential. Fuel injectors precisely spray atomized fuel into the intake manifold or directly into the cylinders (in direct injection systems).

There are three main types of fuel injection systems: direct fuel injection (fuel injected directly into cylinders), ported fuel injection (fuel injected into intake ports), and throttle body fuel injection (fuel injected above the throttle body).

#36. Air Intake System

The air intake system is responsible for delivering clean, filtered air to the engine.

It comprises an air filter to remove dust and impurities from incoming air, and a series of ducts or tubes that guide the filtered air to the intake manifold. The throttle body, part of the air intake system, controls the volume of air entering the engine, thus regulating engine power and speed.

#37. Air Filter

The air filter is a vital component within the air intake system.

The intake manifold distributes airflow to the engine cylinders. The air filter is positioned upstream of the intake manifold to clean incoming air.

In some V6 and V8 engines, the intake manifold may consist of multiple sections or pieces.

The air intake path typically includes the air filter housing, the air filter itself, the intake boot (snorkel), the throttle body, the intake manifold plenum, the runners (individual intake passages), and finally the cylinders. The throttle valve within the throttle body regulates airflow to control engine RPM.

#38. Fuel Delivery System

The fuel delivery system ensures that the engine receives the correct amount of fuel to mix with the incoming air for optimal combustion.

Key components include the fuel pump (to deliver fuel from the tank), fuel injectors (for precise fuel metering and injection), and the fuel tank (to store fuel). Fuel injectors spray fuel into the intake manifold or cylinders, where it mixes with air. This air-fuel mixture is then compressed and ignited in the cylinders to produce power.

#39. Lubrication System

The lubrication system‘s primary function is to minimize friction and wear between moving engine parts.

It relies on engine oil as the lubricant, an oil pump to circulate the oil, and a network of oil channels to distribute oil to various engine components (bearings, pistons, crankshaft, camshaft, etc.). Without proper lubrication, engine parts would experience excessive friction, leading to rapid wear and severe engine damage.

#40. Cooling System

Engines generate significant heat during operation. The cooling system prevents overheating, which can cause severe engine damage.

The cooling system uses a mixture of water and coolant (antifreeze) to regulate engine temperature.

The water pump circulates coolant through the engine block and cylinder head, absorbing heat. The heated coolant then flows to the radiator, where heat is dissipated to the surrounding air. A thermostat regulates coolant flow to maintain the engine at its optimal operating temperature for efficiency and longevity.

Read more: 50 Basic Parts of a Car With Name & Diagram

Common Engine Problems and Symptoms

With numerous complex mechanisms operating at high speeds, engine parts can wear down over time, leading to various problems. Here are some common engine problems and their associated symptoms:

- Poor compression: Results in loss of power, engine misfiring, or a no-start condition.

- Cracked engine block: Causes engine overheating, white smoke from the exhaust, or coolant leaks (often visible on the engine block’s exterior).

- Damaged Pistons, Rings, and/or Cylinders: May exhibit rattling sounds, blue smoke from the exhaust (oil burning), rough idle, or failure to pass emissions tests.

- Broken or worn Rods, Bearings, & Pins: Can cause tapping or ticking sounds, low oil pressure readings, metal shavings found in the engine oil during oil changes, or rattling noises upon acceleration.

Car engines, while seemingly complex, have a fundamental task: to propel your vehicle. Maintaining your vehicle with regularly scheduled oil changes, fluid flushes, and timely replacement of belts and hoses is crucial for preventing engine problems and ensuring long-term reliability.

Car Engine Parts Video

[Car Engine Parts Video](URL to be inserted if available, otherwise remove this section as per instructions – no video link provided in original article)

FAQs About Car Engines

What Is an Engine?

An engine, or motor, is a machine designed to convert one or more forms of energy (chemical, thermal, electrical, etc.) into mechanical energy, which is used to do work. Most modern vehicles utilize internal combustion engines (ICEs), which burn fuel and use the resulting expansion of gases to move mechanical parts and generate power.

How Does a Car Engine Work?

A car engine operates through a cycle of intake, compression, combustion, and exhaust within cylinders. The engine consists of fixed cylinders and moving pistons. The expanding combustion gases push the pistons, which in turn rotate the crankshaft. This rotational motion is then transmitted through the powertrain to drive the vehicle’s wheels.

What are the different parts of an engine?

The main parts of a car engine include: the engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain or belt, valvetrain components (valves, rocker arms, pushrods/lifters), fuel injectors, and spark plugs. These parts work together to generate power and drive the vehicle.

How many parts are in a car engine?

A typical internal combustion engine consists of around 200 individual parts that require maintenance and potential replacement over their lifespan. In contrast, an electric vehicle’s powertrain has significantly fewer parts, approximately 20, due to its simpler design.

What Engine Does My Car Have?

You can typically identify your car’s engine type using the Vehicle Identification Number (VIN). The VIN can be found in your owner’s manual, on the driver’s side dashboard (visible through the windshield), or on the doorjamb sticker. The eighth digit of the VIN usually contains information about the engine type installed in your vehicle.

Related Post

50 Basic Parts of a Car With Name & Diagram