Diesel engines are celebrated for their fuel efficiency and robust power, making them the preferred choice for heavy-duty vehicles and trucks. To truly appreciate the mechanics and maintenance of these engines, understanding their core components is crucial. This guide will explore the main parts of a car diesel engine, detailing their functions and importance for optimal performance and potential troubleshooting.

Before diving into the specific parts, it’s important to differentiate between remanufactured and rebuilt engines. Remanufactured engines, like those championed by experts such as ATL Diesel, offer a cost-effective and environmentally conscious approach by giving existing parts a new lease on life. While rebuilding an engine might seem like a DIY endeavor, it carries risks and potential for errors. Opting for professionally remanufactured parts ensures quality and reliability, providing peace of mind and potentially saving costs in the long run.

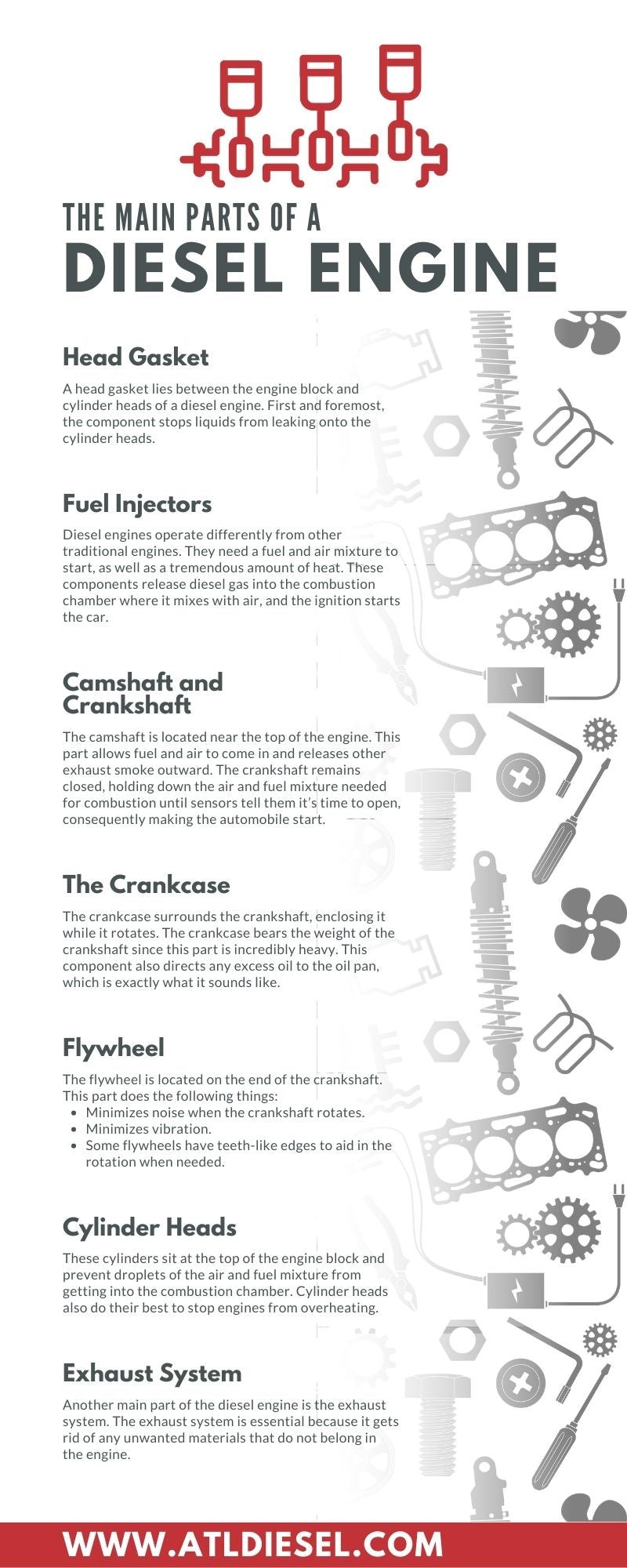

Head Gasket: Sealing the Combustion Chamber

The head gasket is a critical sealing component situated between the engine block and cylinder heads. Its primary function is to prevent coolant and oil leaks into the cylinders. Maintaining a dry cylinder head is essential for proper air and fuel mixture, which is vital for engine ignition. Head gaskets endure extreme temperature fluctuations, transitioning from the cool environment of the coolant system to the intense heat of combustion. This thermal stress makes them susceptible to warping and failure over time. Regular checks for signs of head gasket issues are crucial for preventing more significant engine problems.

Fuel Injectors: Delivering Precise Fuel Bursts

Diesel engines rely on a precise combination of fuel, air, and significant heat for combustion, differing fundamentally from gasoline engines. Fuel injectors are at the heart of this process. These sophisticated components spray atomized diesel fuel directly into the combustion chamber. Here, the diesel mixes with compressed air, and the heat generated from compression initiates ignition. The precise timing and quantity of fuel delivered by injectors are paramount for efficient combustion and engine performance. But what happens after combustion within the chamber?

Camshaft and Crankshaft: Orchestrating Engine Movement

The camshaft, positioned near the top of the engine, plays a vital role in controlling the engine’s breathing. It manages the intake and exhaust valves, allowing air and fuel to enter the cylinder and exhaust gases to escape after combustion. The camshaft’s lobes are designed to open and close these valves at precise moments in the engine cycle, ensuring synchronized combustion.

Working in tandem with the camshaft is the crankshaft, a complex component that translates the linear motion of pistons into rotational motion, the driving force of the vehicle. Both the camshaft and crankshaft operate with rotary motion, similar to a bicycle’s pedals and gears. The crankshaft rotates within the crankcase, converting the reciprocating piston movement into the rotational energy that powers the wheels. Sensors throughout the engine monitor conditions and signal the camshaft and crankshaft to coordinate valve and piston movements for optimal engine function.

The Crankcase: Housing and Protecting the Crankshaft

The crankcase acts as a protective housing for the crankshaft, fully enclosing it as it rotates. Beyond protection, the crankcase is designed to bear the considerable weight of the crankshaft itself. It also serves as a crucial part of the engine’s lubrication system. Excess oil is channeled by the crankcase towards the oil pan, located at the bottom of the engine. The oil pan acts as a reservoir, collecting oil that isn’t immediately needed for lubrication. Larger vehicles may incorporate multiple oil pans to manage larger oil volumes, while smaller cars typically have a single pan.

Flywheel: Smoothing Engine Operation

The flywheel, typically located at the end of the crankshaft, is a key component in smoothing out the diesel engine’s power delivery. Its functions are multifaceted:

- Noise Reduction: The flywheel dampens the mechanical noise generated by the rotating crankshaft, contributing to a quieter engine operation.

- Vibration Dampening: Its mass and rotational inertia minimize engine vibrations, leading to a smoother driving experience.

- Starting Assistance: Some flywheels feature toothed edges that engage with the starter motor, aiding in the initial rotation of the crankshaft during engine start-up.

The Main Parts of a Diesel Engine

The Main Parts of a Diesel Engine

Cylinder Heads: Ensuring Optimal Mixture and Temperature Control

Maintaining the correct air and fuel mixture for combustion is paramount in a diesel engine. Cylinder heads are designed to ensure this precision. Positioned atop the engine block, cylinder heads prevent any leakage of the crucial air-fuel mixture from the combustion chamber. They provide a contained space for the combustion process to occur efficiently.

Furthermore, cylinder heads play a critical role in engine temperature management. Diesel engines generate significant heat during operation. Cylinder heads incorporate coolant passages that facilitate the flow of coolant. This coolant absorbs heat from the combustion process and circulates towards the radiator. The thermostat regulates coolant flow through the cylinder heads, ensuring efficient heat dissipation and preventing engine overheating. Larger engines typically have more cylinder heads, providing increased coolant flow capacity to manage higher heat loads.

Exhaust System: Managing Combustion Byproducts

The exhaust system is another fundamental component of a diesel engine. Its primary role is to safely remove waste gases produced during combustion, preventing harmful emissions from entering the passenger cabin and the environment. Analyzing exhaust smoke color can also provide valuable insights into potential engine problems.

- Black Smoke: Often indicates an issue with the fuel injector pump, leading to an excessively rich fuel mixture. The engine is receiving too much fuel relative to air, causing incomplete combustion.

- Blue Smoke: Signifies engine oil burning within the combustion chamber. This could be due to worn piston rings or valve seals, allowing oil to leak into the combustion area.

- White Smoke: Typically suggests coolant leakage into the combustion chamber. This can be a sign of a head gasket failure or cracked cylinder head, and can lead to engine overheating and potential damage.

Understanding the main parts of your car diesel engine is more than just technical knowledge; it’s a proactive approach to vehicle maintenance and longevity. Familiarity with these components empowers drivers to recognize potential issues early and seek timely professional help, preventing minor problems from escalating into major repairs. When replacement parts become necessary, consider the advantages of remanufactured diesel engine parts from reputable suppliers like ATL Diesel. Remanufactured parts offer a cost-effective, environmentally responsible alternative to new parts, delivering comparable performance and reliability. Choosing remanufactured parts is not only budget-friendly but also contributes to a sustainable approach by reducing waste and extending the lifespan of valuable engine components.