Carbon fiber is increasingly popular in the automotive world, prized for its strength and lightness. Initially used in racing cars, it’s now common in passenger vehicles as manufacturers seek to improve fuel efficiency and meet stricter environmental standards. Beyond OEM applications, many car enthusiasts also choose aftermarket carbon fiber parts to enhance their vehicles’ performance and aesthetics.

As carbon fiber gains traction, a key question arises among car lovers and auto professionals alike: Can You Paint Carbon Fiber Car Parts? This question sparks debate, with strong opinions on both sides. Let’s delve into the complexities of painting carbon fiber, exploring the challenges and best practices for achieving a flawless finish.

auto refinishing prep technician

auto refinishing prep technician

The Great Debate: To Paint or Not to Paint Carbon Fiber?

For many in auto painting careers, the question of painting carbon fiber isn’t straightforward. A significant faction believes that painting carbon fiber is often unnecessary and potentially detrimental. Their argument stems from two main points:

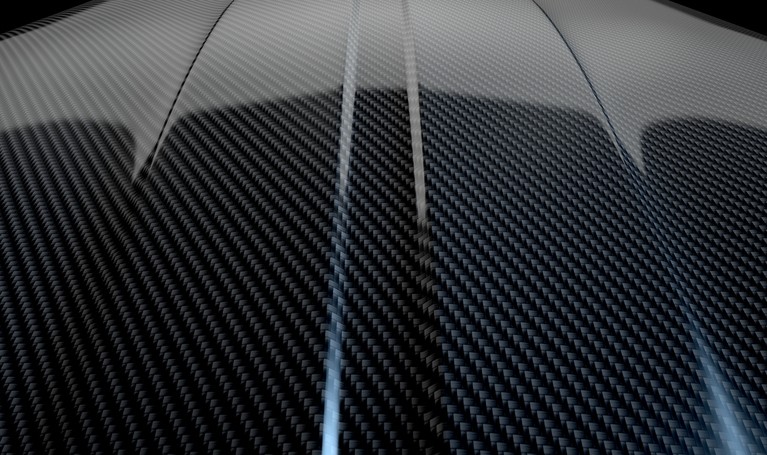

- Aesthetic Value of Carbon Fiber: Carbon fiber boasts a distinctive woven pattern that is visually striking and often considered a premium aesthetic feature. Proponents of leaving it unpainted argue that investing in carbon fiber parts, which are generally more expensive than their counterparts made from other materials, is partly for this unique visual appeal. Painting over it would negate this key benefit, hiding the very characteristic that makes carbon fiber desirable to many. Why conceal such an eye-catching material under layers of paint?

- Complexity and Labor: Painting carbon fiber is not as simple as painting metal or plastic car parts. It requires meticulous preparation and technique, often yielding unpredictable results. This labor-intensive process can be time-consuming and costly, leading some professionals to question the practicality of painting carbon fiber, especially when the raw material itself is already visually appealing.

However, the desire for customization is deeply ingrained in car culture. Car enthusiasts frequently personalize their vehicles through paint jobs and modifications. This desire for a unique look often extends to carbon fiber components. For those seeking a specific color scheme or a more integrated aesthetic, painting carbon fiber becomes a compelling option.

Understanding the Unique Challenges of Painting Carbon Fiber

Painting carbon fiber presents unique challenges compared to traditional automotive materials. Students in car painting courses and seasoned auto refinishing prep technicians need to be aware of these key differences:

- Paint Absorption: Carbon fiber’s woven structure is porous and tends to absorb paint at a rapid rate. This characteristic makes achieving an even paint application significantly more difficult. Uneven paint distribution can lead to visible inconsistencies in the finish, potentially revealing the underlying crosshatch pattern of the carbon fiber in certain areas, even after painting.

- Heat Sensitivity: Many modern automotive paints require heat curing to properly set and achieve a durable finish. Unfortunately, carbon fiber is susceptible to warping and buckling under high temperatures. Standard heat curing processes used for metal parts are often unsuitable for carbon fiber. This necessitates alternative, often more complex, curing methods to avoid damaging the carbon fiber structure.

These challenges underscore the need for specialized techniques and careful execution when painting carbon fiber. It’s not a process to be rushed or approached casually.

Step-by-Step Guide to Painting Carbon Fiber Car Parts Successfully

Despite the complexities, painting carbon fiber car parts is achievable with the right approach. Here’s a step-by-step guide to maximize your chances of success:

- Sanding the Clear Coat: Most carbon fiber parts come with a clear coat finish. The first crucial step is to properly sand this clear coat. Wet sanding is highly recommended to minimize the risk of damage. Gentle and even sanding is paramount. Over-sanding can compromise the structural integrity of the carbon fibers and create a rough, uneven surface that is difficult to rectify.

- Primer Application: After sanding, priming is essential. Depending on the type of primer used, multiple coats may be necessary – sometimes up to five coats – to create a smooth, uniform base for the paint. Each primer layer must be allowed to dry thoroughly before applying the next. Patience is key during this stage.

- Painting: Once the primer is fully cured and properly prepared, you can apply your chosen paint color. Apply the paint in thin, even coats, allowing each coat to flash dry before applying the next. This technique helps prevent runs and ensures even coverage, crucial due to carbon fiber’s absorbent nature.

- Buffing (If Necessary): Even with careful application, minor imperfections or unevenness may occur. After the paint is completely dry, buffing the surface can help smooth out these imperfections and achieve a flawless, show-quality finish.

By following these steps meticulously, you can successfully paint carbon fiber car parts and achieve a custom look that complements your vehicle.

Interested in mastering automotive refinishing?

Contact Automotive Training Centres to explore our comprehensive car painting courses and take your skills to the next level!