The brake system is arguably the most critical safety system in any vehicle. It’s composed of numerous parts working in harmony to achieve one primary goal: slowing down or stopping your car effectively and safely when needed. For every driver, understanding the fundamental brake parts in your car is not just beneficial—it’s essential for your safety and vehicle maintenance.

Why should a driver, not just a mechanic, be familiar with the components of their car’s brake system? Firstly, knowledge empowers you to understand how your car’s braking system operates, enhancing your overall driving awareness. Secondly, this understanding has economic advantages. Being informed about brake parts can help you make educated decisions about maintenance and repairs, ensuring you spend appropriately on each component.

In this guide, we will explore the major Brake Parts In Car systems, breaking down their functions and importance.

Chapter 1: Exploring Disc Brake System Parts

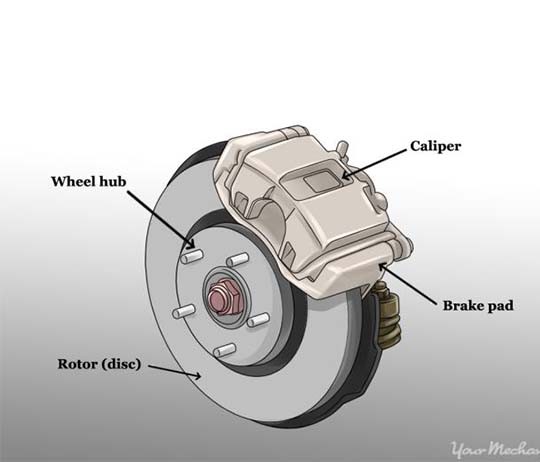

Here are the key brake parts in a disc brake system that every driver should be aware of:

– Brake Pads

Brake pads are crucial components designed as friction blocks that press against the brake rotor. This action generates friction, which is essential to slow down or stop the wheels from rotating. These pads are engineered to create maximum friction against the rotor, ensuring effective stopping power. Brake pads and rotors are designed to work together as a primary braking pair.

Over time, the brake pad linings naturally wear down due to friction. This wear necessitates regular brake pad replacement to maintain optimal braking performance. It’s also important to note that brake pads come in various types, differing primarily in their material composition, each designed for specific performance characteristics and driving conditions.

– Brake Rotor

The brake rotor is another indispensable brake part in a disc brake system. It serves as the surface against which the brake pads apply pressure. When you press the brake pedal, the brake pads clamp onto the rotor, using friction to decelerate the vehicle’s wheels.

Similar to brake pads, brake rotors are subject to wear and tear. As they are used, rotors can become thinner and less effective. Once a brake rotor reaches its minimum recommended thickness, it’s critical to replace it to ensure safe braking. Consulting a reliable brake rotor manufacturer or mechanic is advisable when replacement is needed.

– Brake Caliper

Brake calipers are responsible for controlling the brake pads’ movement. Their primary function is to precisely push the brake pads against the rotor to initiate braking and then retract them when braking is no longer required. This action is crucial for both effective braking and preventing unnecessary wear when the brakes are not in use.

There are two main types of brake calipers: fixed calipers and floating calipers. Fixed calipers remain stationary, using pistons on opposite sides of the rotor to apply even pressure. Floating calipers, on the other hand, move or “float” relative to the rotor, typically using a piston on only one side.

Like other brake parts, brake calipers can also require maintenance or replacement. A common sign of caliper issues is brake fluid leakage, which can compromise braking performance. Regular inspection and maintenance are essential to ensure calipers function correctly.

Brake pads, rotors, and calipers are the core components of a disc brake system, working in concert to provide reliable stopping power.

Chapter 2: Understanding Drum Brake System Parts

While disc brakes are common, drum brakes are still utilized in modern vehicles, particularly on the rear wheels. Drum brake systems operate using a different set of brake parts, including brake shoes, brake drums, and a backing plate.

– Brake Shoes

Brake shoes in a drum brake system perform a similar function to brake pads in a disc system. They are curved components lined with a friction material that presses against the inside surface of the brake drum to create friction and slow the vehicle. Brake shoes consist of a metal base and a specialized drum brake lining material designed for high friction and heat resistance.

Just like brake pads, brake shoes are subject to wear over time. The friction material wears down with use, necessitating periodic brake shoe replacement to maintain effective braking in drum brake systems.

– Brake Drum

The brake drum is a cylindrical metal component that rotates with the wheel. It provides the surface against which the brake shoes press. When the brake shoes are forced outwards against the inner surface of the rotating drum, friction is generated. This friction slows down or stops the rotation of the drum, and consequently, the wheel.

Brake drums are robust but can also wear or become damaged. Overheating and repeated heavy braking can sometimes cause brake drums to warp or become out-of-round. Warped brake drums can lead to reduced braking efficiency and vibrations, requiring replacement.

– Backing Plate

The backing plate is a foundational brake part in a drum brake system. It is a sturdy metal plate that provides structural support and serves as the mounting point for all other drum brake components. The backing plate holds the brake shoes, wheel cylinder, springs, and other brake hardware securely in place within the drum brake assembly. It ensures all components are correctly positioned and function effectively as a cohesive unit.

Chapter 3: Essential Brake System Hardware and Accessories

Beyond the main components of disc and drum brakes, several other brake parts and hardware are crucial for the overall brake system’s functionality. These parts ensure smooth operation and enhance the system’s effectiveness.

– Return Springs

Return springs are specifically used in drum brake systems. Their primary function is to retract the brake shoes away from the brake drum when the brake pedal is released. This action is essential to disengage the brakes, allowing the wheels to rotate freely and preventing unnecessary drag and wear. Return springs ensure that the brake shoes return to their resting position promptly after braking.

– Wheel Cylinder

The wheel cylinder is another key component in drum brake systems. It is a hydraulic device that converts hydraulic pressure from the brake master cylinder into mechanical force. Inside the wheel cylinder are pistons that, when hydraulic pressure is applied, push outwards. This outward movement of the pistons forces the brake shoes against the brake drum, initiating the braking action.

Wheel cylinders are subject to wear and potential leaks due to the constant pressure and brake fluid exposure. Signs of a failing wheel cylinder include brake fluid leaks, reduced braking performance, or a spongy brake pedal feel. Timely wheel cylinder replacement is crucial to maintain effective drum brake operation.

– Anti-Lock Brakes (ABS)

Anti-lock Braking System (ABS) is a vital safety accessory in modern vehicles. It’s designed to prevent the wheels from locking up during hard braking, especially in emergency situations or on slippery surfaces. ABS works by automatically modulating brake pressure to each wheel, preventing wheel lockup and maintaining vehicle stability and steering control.

ABS is particularly beneficial in preventing skidding, allowing drivers to steer around obstacles even during emergency braking. It enhances safety by ensuring the shortest possible stopping distance while maintaining directional control of the vehicle.

Chapter 4: Types of Brake Systems Explained

Understanding brake parts in car also involves knowing the broader classification of brake systems. It’s important to distinguish between a brake component (like a pad or rotor) and a complete brake system, which refers to the overall braking method employed in a vehicle.

Brake systems can be categorized based on their operational mechanism. Here are some main types:

-

Electromagnetic Braking System: These systems utilize electric motors to generate braking force. They are often found in electric and hybrid vehicles, leveraging regenerative braking to convert kinetic energy into electrical energy, which also aids in slowing the vehicle.

-

Hydraulic Brake System: This is the most common type in modern cars. Hydraulic brake systems use brake fluid to transmit force from the brake pedal to the wheel brakes. When the driver presses the brake pedal, it pressurizes the brake fluid, which in turn activates the calipers or wheel cylinders to apply the brakes.

-

Mechanical Brake System: Mechanical brake systems rely on mechanical linkages, such as rods and cables, to transfer force from the brake pedal to the brakes. These systems were more common in older vehicles and are simpler in design but less efficient than hydraulic systems for modern braking needs.

-

Servo Brake System (Vacuum Assisted Braking): Also known as vacuum-assisted or power brakes, these systems amplify the driver’s braking effort. They use engine vacuum to assist the hydraulic system, making it easier for the driver to apply strong braking force without excessive pedal pressure. This is standard in most modern vehicles, providing enhanced braking with less driver exertion.

Within these system types, the two primary brake designs are disc brakes and drum brakes, as discussed earlier. While they share the fundamental principle of using friction to slow a vehicle, their design, components, and application differ significantly. Both types are essential brake parts in car design and require regular maintenance and eventual replacement due to wear.

Conclusion

In summary, a standard car typically has four brakes: two front and two rear. The front brakes generally handle a larger proportion of the braking force due to weight transfer during deceleration. Understanding the various brake parts in car systems is invaluable for every vehicle owner. This knowledge equips you to better understand vehicle maintenance needs and address potential issues effectively, whether it involves brake pads, rotors, shoes, or any other component of your car’s essential braking system. Knowing your brake parts is a step towards safer driving and responsible car ownership.