General Motors (GM), a long-standing leader in automotive innovation, is pushing the boundaries of vehicle design and manufacturing. For years, they’ve been at the forefront of vehicle lightweighting, achieving significant mass reductions in their new models. Now, to further enhance vehicle efficiency and performance, GM is collaborating with Autodesk, leveraging cutting-edge technologies like generative design and additive manufacturing. This partnership marks a significant step towards the future of automotive engineering, particularly in the realm of electric and zero-emission vehicles.

The Drive for Lightweighting and Innovation

GM’s commitment to lightweighting is evident in their recent achievements. Since 2016, they have successfully launched 14 new vehicle models, collectively reducing vehicle mass by over 5,000 pounds – an impressive average of more than 350 pounds per vehicle. The benefits of lighter vehicles are substantial: improved fuel efficiency, reduced carbon emissions, and cost savings for drivers. This focus on efficiency is not just environmentally responsible, but also crucial for meeting evolving consumer demands and regulatory standards.

To accelerate their lightweighting efforts and explore new design possibilities, GM is adopting Autodesk’s generative design software. This makes them the first major North American automaker to embrace this innovative technology, moving beyond the limitations of traditional design optimization techniques. Generative design represents a paradigm shift in how automotive components are conceived and developed.

Understanding Generative Design in Automotive Engineering

Generative design is an AI-powered technology that empowers engineers to explore a vast design space, generating multiple high-performing design options based on specified engineering and manufacturing constraints. Engineers define parameters such as material, weight, strength, and manufacturing methods, and the software algorithms then autonomously create numerous valid design solutions. This process allows for the rapid evaluation of a far greater number of design iterations than previously possible, freeing engineers from time-consuming repetitive tasks and enabling them to focus on higher-level innovation.

Ken Kelzer, GM Vice President, Global Vehicle Components and Subsystems, emphasizes the transformative potential of this technology: “This disruptive technology provides tremendous advancements in how we can design and develop components for our future vehicles to make them lighter and more efficient. When we pair the design technology with manufacturing advancements such as 3D printing, our approach to vehicle development is completely transformed and is fundamentally different to co-create with the computer in ways we simply couldn’t have imagined before.”

Case Study: Redesigning a Seat Bracket with Generative Design and AutoCAD Principles

To demonstrate the practical benefits of generative design, GM and Autodesk engineers collaborated on a proof-of-concept project focused on redesigning a seat bracket – a critical component for seatbelt fastening. Using generative design software, they input parameters related to connection points, strength requirements, and mass targets. The software generated over 150 viable design options, revealing innovative geometries that human engineers might not have conceived through traditional Autocad Car Parts design processes.

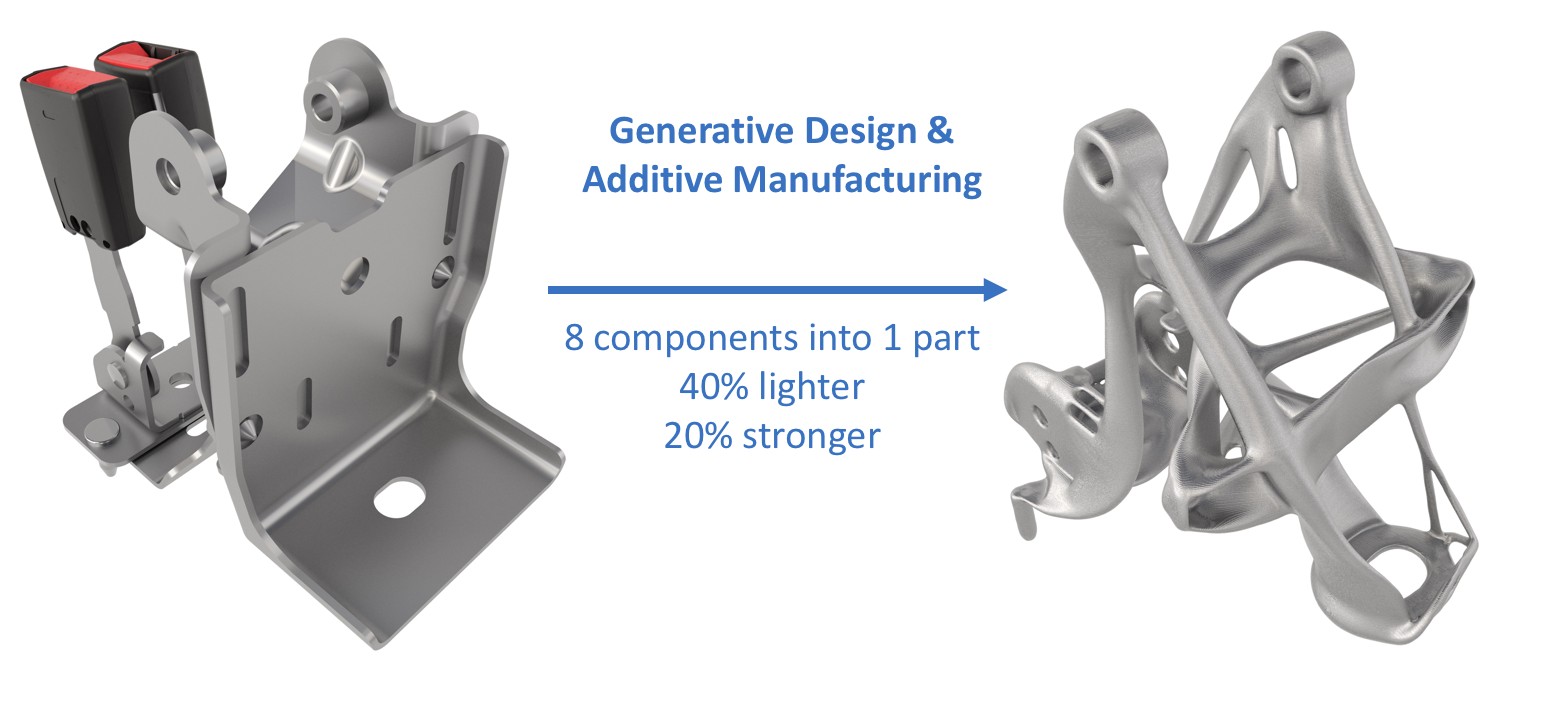

The team selected a groundbreaking new design characterized by an organic, lattice-like structure. This generatively designed seat bracket achieved a remarkable 40% weight reduction and a 20% strength increase compared to the original part. Furthermore, generative design facilitated part consolidation, integrating eight separate components into a single, 3D-printed part. This not only simplifies assembly but also enhances structural integrity.

Comparison of an original seat bracket with a new, generatively designed, and 3D-printed iteration showcasing lightweighting and part consolidation.

The Synergy of Generative Design and Additive Manufacturing for Car Parts

GM’s expertise in additive manufacturing, or 3D printing, further amplifies the advantages of generative design. With over 30 years of experience and an extensive arsenal of 3D printing equipment, GM is uniquely positioned to translate these innovative designs into tangible automotive components. They operate more than 50 rapid prototyping machines, producing over 250,000 prototype parts in the last decade.

Kevin Quinn, GM Director of Additive Manufacturing, highlights the synergy: “With our long-standing expertise in additive manufacturing, we see incredible opportunities for generative design. The seat-bracket is just a small demonstration of the potential mass and strength improvements when we apply these technologies to many of the 30,000+ parts in our vehicles. Maybe even more exciting are the far-reaching transformations we can imagine as we move into an era of electric and autonomous vehicles.”

The seat bracket project serves as a compelling example of the potential for mass and strength optimization achievable through the combined power of generative design and 3D printing. This approach can be applied to a wide range of AutoCAD car parts, from structural elements to interior components, leading to significant improvements in vehicle performance and efficiency.

A Multi-Year Alliance for Automotive Innovation

The seat bracket initiative is just the beginning of a long-term collaboration between GM and Autodesk. This alliance will focus on exploring further applications of generative design, additive manufacturing, and materials science in automotive engineering. Executives and engineers from both companies will engage in ongoing exchanges of ideas, knowledge, and expertise.

For instance, GM engineers participated in a generative design residency program at Autodesk’s Pier 9 technology center. This immersive experience facilitated hands-on learning and collaborative innovation.

GM engineers Mike Van De Velde and Paul Wolcott at Autodesk’s Pier 9 additive manufacturing lab in San Francisco, working on generative design for automotive applications.

GM also leverages Autodesk’s comprehensive software suite, including Fusion 360 for generative design access, Netfabb for lattice optimization and metal additive simulation, and Alias, Recap Pro, and Meshmixer for various design and modeling tasks. These tools provide GM engineers with a powerful and integrated platform for pushing the boundaries of automotive design and manufacturing.

Transforming the Future of Vehicle Design and Performance

Scott Reese, Autodesk Senior Vice President for Manufacturing and Construction Products, underscores the broader implications of generative design: “Generative design is the future of manufacturing, and GM is a pioneer in using it to lightweight their future vehicles. But the benefits for GM go well beyond lightweighting. What really separates generative design from past technologies is the ability to consolidate many parts into one and the ability to dramatically compress the product development process. Engineers get hundreds of ready-to-manufacture design options they could never come up with manually and it happens in a fraction of the time it would take to validate a single design the old way. GM can take advantage of those benefits right now for parts like the seat-bracket, and they are already looking to the longer-term potential to transform the consumer experience for their vehicles.”

GM envisions a future where these advancements contribute to more than just fuel savings. Reduced vehicle weight can extend the range of electric vehicles and create more spacious interiors for enhanced passenger comfort. Generative design and additive manufacturing are providing “vehicle designers a canvas on which to explore designs and shapes not seen today,” as GM stated in their press release.

Mike Grau, an Autodesk engineer collaborating with GM, encapsulates the excitement surrounding this partnership: “GM has an incredible history of innovation. Through our collaboration, we’re tapping into GM’s heritage and bringing new technologies into the mix to further invigorate that culture of innovation. GM is taking a bold leap into the future. I can’t wait to see the incredible advances to their vehicles that is going to come out of our alliance.”

This collaboration between GM and Autodesk, centered around generative design and advanced manufacturing techniques, is poised to revolutionize the automotive industry, paving the way for lighter, more efficient, and ultimately, better vehicles. The integration of these technologies into the design and production of AutoCAD car parts and beyond, signifies a major leap forward in automotive engineering and manufacturing.