The automotive industry is in constant motion, driven by innovation and the relentless pursuit of improvement. As new car models emerge and existing ones evolve, the materials that constitute them are also undergoing a transformation. Among these advancements, aluminum car parts have risen to prominence, offering a compelling blend of performance enhancement and efficiency gains. For car enthusiasts and industry professionals alike, understanding the intricacies of aluminum in automotive manufacturing is becoming increasingly crucial.

Aluminum, a remarkably abundant element on Earth, presents unique challenges and opportunities in manufacturing. Its inherent properties require specialized techniques to harness its full potential in automotive applications. So, how exactly are aluminum car parts made? What technologies do aluminum car parts manufacturers employ? Let’s delve into the fascinating world of aluminum auto parts and uncover the processes and advantages that are reshaping modern vehicles.

Manufacturing Aluminum Car Parts: A Detailed Look

Creating metal auto parts involves a variety of methods, each with its own set of advantages and cost implications. The choice of manufacturing technique often depends on factors like production volume, part complexity, and budget constraints. For high-volume production, certain methods offer economies of scale, while for intricate designs or smaller runs, different approaches may be more suitable.

For mass production of aluminum car parts, investing in advanced machinery like CNC milling machines becomes a viable option. Conversely, for smaller, custom batches, techniques like laser cutting might suffice. Let’s explore some key manufacturing methods in detail.

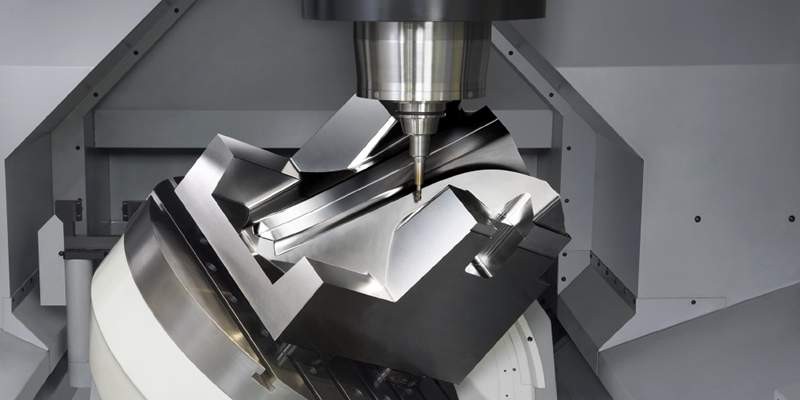

CNC Machining for Aluminum Automotive Components

CNC Machining stands for Computer Numerical Control Machining, an automated manufacturing process that utilizes computer-controlled machines to precisely shape metal parts. This technology allows for the creation of complex geometries and intricate features in aluminum components with exceptional speed and accuracy.

CNC aluminum machining offers significant advantages over traditional manual methods. Firstly, it achieves superior levels of accuracy and repeatability, ensuring consistent part quality across large production runs. Secondly, it dramatically reduces cycle times, leading to increased productivity and faster turnaround.

However, it’s important to note that CNC machining for aluminum is generally considered a more expensive manufacturing route, especially for very high volumes. Therefore, it is often most cost-effective when producing large quantities where the per-part cost can be optimized, or when high precision and complex designs justify the investment.

Aluminum Die Casting: High-Volume Production

Die casting is a robust industrial manufacturing process ideally suited for high-volume production of aluminum parts. It involves injecting molten aluminum alloy into a mold cavity under immense pressure. Once the aluminum solidifies and cools within the mold, the mold is opened, and the finished part is ejected.

Die casting is a versatile technique employed across numerous industries beyond automotive, including aerospace, medical equipment, consumer goods, electronics, and more. The tooling, known as dies, can be tailored to create a wide array of part shapes and sizes, making it a highly adaptable manufacturing solution.

Aluminum 3D Printing: Prototyping and Specialized Parts

Aluminum 3D printing, also known as additive manufacturing, represents a cutting-edge approach to creating three-dimensional aluminum objects layer by layer from a digital design. While 3D printing is widely recognized for its use with plastics, its application to metals like aluminum is rapidly expanding.

Metal 3D printing techniques, such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), utilize high-powered lasers to selectively fuse together fine powders of aluminum alloy. The laser beam precisely traces the cross-section of the part layer by layer, melting and solidifying the aluminum particles. As each layer is completed, the build platform lowers, and a new layer of powder is spread, repeating the process until the entire 3D part is formed.

Parts produced by aluminum 3D printing often exhibit enhanced structural integrity compared to other 3D printing methods due to the complete fusion of the metal particles. Currently, aluminum 3D printing is primarily utilized for creating prototypes, highly customized components, and specialized external body parts where design complexity or low-volume production runs make it a compelling option.

Unique Characteristics of Aluminum Car Parts

Aluminum car parts stand apart from their counterparts made of other metals due to a unique set of inherent properties. These properties not only influence manufacturing processes but also contribute significantly to vehicle performance and characteristics. A key advantage of aluminum is its ability to enhance a car’s performance while simultaneously reducing weight, which directly translates to improved fuel efficiency. Let’s examine these distinguishing characteristics in detail.

1. Strength: High Strength-to-Weight Ratio

While steel is often perceived as the benchmark for strength in automotive construction, aluminum offers a remarkable strength-to-weight ratio. This means that for a given level of strength, aluminum components are significantly lighter than steel counterparts. Aluminum’s strength stems from its atomic structure, which resists breakdown even under stress. Unlike steel, which can become brittle at low temperatures, aluminum retains its toughness even in cold environments. This inherent strength makes aluminum an ideal material for critical automotive components as well as for industries like aerospace, construction (skyscrapers), and appliance manufacturing.

2. Flexibility: Design Versatility

Aluminum is known for its ability to withstand considerable stress and pressure, making it a robust material. However, it also possesses a degree of flexibility, allowing it to be formed and shaped without fracturing. This combination of strength and flexibility provides designers with greater freedom and versatility in automotive design. This characteristic is crucial for applications ranging from intricate aircraft components to lightweight bicycle frames, and allows automotive manufacturers to create complex and optimized shapes.

3. Malleability: Shaping Complex Forms

Malleability, the ability of a material to be deformed under compressive stress without fracturing, is another key attribute of aluminum. Aluminum exhibits exceptional malleability, allowing it to be easily extruded through dies to create a wide variety of shapes. This makes it highly suitable for manufacturing automotive body panels, complex aircraft fuselages, and intricate architectural elements. Furthermore, aluminum can be readily formed into complex shapes through bending, stamping, and other shaping processes.

4. Conductivity: Efficient Heat and Electrical Transfer

Aluminum is an excellent conductor of both heat and electricity. While copper is traditionally favored for electrical wiring due to its higher conductivity, aluminum offers a significant weight advantage. Although achieving the same level of electrical conductivity requires a larger volume of aluminum compared to copper, the weight savings are substantial. In fact, an aluminum conductor can weigh approximately half as much as a copper conductor with equivalent electrical conductivity, as recognized by the American Society for Testing Materials (ASTM). This property is increasingly valuable in electric vehicles and other applications where weight optimization is critical.

5. Corrosion Resistance: Longevity and Reduced Maintenance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This inherent corrosion resistance eliminates the need for heavy anti-corrosion coatings often required for steel parts, further contributing to weight reduction. For decades, the automotive and aerospace industries have leveraged aluminum’s corrosion resistance and high strength-to-weight ratio. This durability translates to longer part lifespan, reduced maintenance requirements, and enhanced vehicle longevity, making aluminum a cost-effective and reliable material choice for automotive applications.

Common Aluminum Alloys in Car Parts

Modern cars are complex assemblies, comprising approximately 30,500 individual parts, including the exterior body panels. Aluminum alloys, engineered variations of pure aluminum, are extensively used in automotive manufacturing due to their enhanced properties, particularly their superior rust resistance and lightweight nature. A wide range of aluminum alloys are specifically formulated for different automotive applications, each offering a unique balance of properties. Some common aluminum alloy series used in car manufacturing include:

- Aluminum Alloy 1100 series: High purity aluminum, excellent corrosion resistance, good workability.

- Aluminum Alloy 4032: High silicon content, low thermal expansion, good wear resistance, often used for pistons.

- Aluminum Alloy 3105, 3003, and 3004 series: Good weldability, moderate strength, commonly used for roofing and siding, and some automotive trim.

- Aluminum Alloy 2024 series: High strength, aircraft alloy, often used in structural components and wheels, but lower corrosion resistance.

- Aluminum Alloy 5005, 5182, 5083, 5052, and 5251 series: Excellent corrosion resistance, good weldability, medium to high strength, used for body panels and structural parts.

- Aluminum Alloy 6022, 6061, 6181, and 6016 series: Versatile alloys, good strength, weldability, and corrosion resistance, widely used for automotive frames, body panels, and extrusions.

- Aluminum Alloy 7046 and 7003 series: High strength alloys, used for demanding structural applications.

The Multifaceted Benefits of Aluminum Auto Parts

Aluminum auto parts offer a compelling array of advantages that extend beyond mere aesthetics. They represent a smart investment in vehicle performance, longevity, and environmental responsibility. Aluminum components can contribute to reduced repair costs, smoother vehicle operation, and a smaller environmental footprint due to their recyclability and corrosion resistance. Let’s explore the key benefits in detail.

1. Performance Enhancement: Agility and Responsiveness

The automotive industry’s relentless pursuit of performance gains has led to the increasing adoption of innovative materials like aluminum. Typically, aluminum is between 10% to 40% lighter than steel. This significant weight reduction directly translates to improved vehicle agility, acceleration, and braking performance. The strength of aluminum allows manufacturers to utilize thinner panels and fewer structural members without compromising safety or structural integrity. Furthermore, aluminum’s inherent flexibility enables design innovations, allowing companies like Ford Motor Company to create vehicle shapes that optimize space utilization, particularly in areas like the cockpit.

2. Precision and Repeatability: Consistent Quality

Aluminum, being a relatively soft metal compared to steel, is exceptionally well-suited to precision manufacturing processes. Various techniques can be employed to work with aluminum, allowing for fine adjustments and intricate detailing. Its softness facilitates maintaining tight tolerances and achieving high levels of precision in car part manufacturing. Moreover, aluminum alloys exhibit excellent repeatability in manufacturing, ensuring consistent quality and dimensional accuracy across large production runs. This consistency is crucial for ensuring reliable performance and interchangeability of parts.

3. Enhanced Safety: Energy Absorption

Today, aluminum constitutes a significant portion of the body panels in modern vehicles sold globally. This widespread adoption is driven by aluminum’s superior safety characteristics compared to steel. For instance, aluminum can absorb approximately twice the amount of impact energy as steel of comparable strength. Additionally, aluminum’s deformation behavior during a crash further enhances safety; it expands and absorbs more crash energy than steel, providing increased protection to vehicle occupants.

4. Durability and Longevity: Extended Lifespan

Aluminum car parts are inherently more resistant to corrosion and wear than steel parts. This translates to a longer lifespan for aluminum components and reduced maintenance requirements over the vehicle’s lifetime. The enhanced durability makes aluminum parts particularly well-suited for vehicles operating in harsh environments, such as off-road vehicles or military applications where exposure to corrosive elements is common. The extended lifespan and durability of aluminum car parts contribute to a vehicle’s overall value and long-term reliability.

5. Fuel Efficiency: Reduced Weight, Lower Consumption

Comparing aluminum car parts to steel counterparts reveals a significant weight reduction – aluminum is approximately 24% lighter than steel. In an era of increasing fuel costs and environmental consciousness, this weight reduction is a critical advantage. The automotive industry is actively exploring further opportunities to maximize the use of aluminum to improve fuel efficiency. This includes incorporating aluminum into more body panels, optimizing part thicknesses, and developing new aluminum alloys that further reduce weight without compromising performance or safety. Lighter vehicles require less energy to accelerate and maintain speed, directly resulting in improved fuel economy and reduced emissions.

6. Resilient and Lightweight: Optimal Performance Balance

Despite perceptions of aluminum being weak or brittle, it possesses remarkable resilience and superior properties compared to steel in many applications. This is due to aluminum’s unique atomic arrangement in a hexagonal crystal structure, unlike the solid crystalline structure of steel. This structural difference contributes to aluminum’s higher strength-to-weight ratio. In fact, approximately 70% of cars manufactured globally today utilize aluminum extensively, primarily due to its optimal balance of strength and low weight, contributing to both performance and fuel efficiency.

7. Flawless Functionality: Improved Assembly and Reliability

The aluminum industry has made significant advancements in product quality over recent decades. Technological innovations and material science breakthroughs have enabled manufacturers to create aluminum connections and components that are stronger, lighter, and easier to assemble. These improvements have resulted in enhanced product durability, improved functionality, and increased reliability of aluminum car parts. As a result of these ongoing advancements, the range of applications for aluminum in automotive manufacturing continues to expand dramatically.

Diverse Applications of Aluminum Car Parts

The applications of aluminum car parts are vast and continue to grow as automotive technology advances. Aluminum’s versatility and beneficial properties make it suitable for a wide range of components throughout a vehicle. Here are some common applications of aluminum in car manufacturing:

- Aluminum wheels (lightweight, improved handling)

- Mirrors (lightweight, corrosion resistant)

- Valve covers (heat dissipation, weight reduction)

- Engine blocks (weight reduction, improved thermal management)

- After-market auto parts (customization, performance enhancement)

- Aluminum transmission housings (weight reduction, durability)

- Wheel spacer parts (precision, lightweight)

- Ornaments and Logos (aesthetic appeal, corrosion resistance)

- Aluminum brackets (structural support, lightweight)

- Carburetors housings (precision, lightweight)

- Impellers and fan clutch parts (lightweight, efficient operation)

- Air filter adaptors (lightweight, precise fit)

- Aluminum handles (lightweight, durable)

- Alternator housings (heat dissipation, weight reduction)

The Expanding Trend of Aluminum in Modern Vehicles

The aluminum industry is dynamic and continuously evolving, driven by innovation and growing demand from sectors like automotive. A significant trend already underway is the increased utilization of aluminum in electric vehicles (EVs). As EVs gain popularity and battery technology progresses, aluminum becomes even more critical. Its lightweight nature helps offset the weight of heavy battery packs, maximizing range and efficiency in EVs.

Another prominent trend is the expanding use of aluminum in hybrid vehicles. As consumers increasingly seek fuel-efficient and lower-emission transportation options, hybrid vehicles are becoming more prevalent. Aluminum’s lightweight properties are equally advantageous in hybrid vehicles, contributing to improved fuel economy and reduced environmental impact.

Looking ahead, the future of aluminum in cars is bright. We are likely to witness even greater adoption of aluminum in electric and hybrid vehicles, as well as in safety-critical components where its strength and energy absorption capabilities are paramount. This positive trajectory is promising news for aluminum car parts manufacturers and the automotive industry as a whole.

Conclusion: Aluminum – Shaping the Future of Automotive

As we have explored, aluminum car parts offer a compelling combination of durability, longevity, and performance benefits. Beyond their functional advantages, aluminum components also contribute to a modern and sophisticated vehicle aesthetic.

If you are seeking reliable and experienced aluminum car parts manufacturers, WayKen stands ready to be your trusted partner. We offer a comprehensive suite of CNC Machining capabilities, including 3, 4, and 5-axis machining, enabling us to produce complex and precise aluminum components. Our extensive material selection includes aluminum, steel, titanium, plastics, and more, catering to diverse automotive requirements.

Our team of skilled engineers and state-of-the-art equipment ensures the highest levels of precision and quality in every automotive part we produce. From individual prototypes for testing and validation to small-batch production runs, we are equipped to assist you at every stage of your project. Get a free quote today and discover how WayKen can help you bring your aluminum car part designs to life!

FAQs About Aluminum Car Parts

What specific car parts are commonly made of aluminum?

Numerous car parts are frequently manufactured using aluminum alloys. These include critical components like the engine block, cylinder heads, intake and exhaust manifolds, and transmission cases. The strategic use of aluminum in these parts significantly reduces the overall vehicle weight, which directly enhances fuel efficiency and improves handling.

Are aluminum car parts more expensive than steel parts?

While the initial cost of raw aluminum can fluctuate, aluminum car parts are not necessarily prohibitively expensive. A significant portion of aluminum used in automotive manufacturing comes from recycled sources, which helps to control costs. The final price of aluminum car parts depends on various factors, including the complexity of the part design, production volume, and the availability of recycled aluminum. However, the long-term benefits of aluminum, such as increased fuel efficiency, reduced maintenance due to corrosion resistance, and extended lifespan, can often offset any potential initial cost difference compared to steel parts.

What specific grade of Aluminum is typically used for car bodies?

The specific grade of aluminum alloy chosen for car body panels varies depending on the vehicle manufacturer and the specific panel application. However, a commonly used alloy for car bodies is high-strength aluminum alloy 6061 T6. This alloy offers an excellent balance of strength, formability, and corrosion resistance. It is frequently employed for front fenders, hoods, doors, trunk lids, roof rails, and other body panels that require both structural integrity and a smooth surface finish. Other aluminum alloys used for car bodies include 7075, 7074, and 2024, each offering specific properties tailored to different panel requirements.