Like the human heart, a car engine is the powerhouse of your vehicle. It’s a complex system, not a single piece, composed of numerous components working in perfect harmony to convert fuel into motion. While you might recognize some car engine parts names, understanding their functions and interactions is crucial for any car owner, whether you’re a seasoned mechanic or a curious driver.

This comprehensive guide, brought to you by the automotive experts at cardiagxpert.com, will take you on a detailed journey through the intricate world of car engine parts. We’ll explore what each part does, how they work together, and why understanding them is essential for maintaining your vehicle’s health and performance. Whether you’re looking to diagnose a problem, perform basic maintenance, or simply expand your automotive knowledge, this guide to All Car Engine Parts Names is your ultimate resource.

Understanding the Heart of Your Car: What is a Car Engine?

At its core, a car engine, specifically an internal combustion engine (ICE), is a marvel of engineering designed to transform the chemical energy stored in fuel into the kinetic energy that propels your car. Imagine a controlled series of explosions happening within a robust metal structure – that’s essentially what powers your vehicle.

This process begins with a spark that ignites a precisely measured mixture of fuel vapor and air inside a confined space called a cylinder. This rapid burning, or combustion, causes the mixture to expand violently, generating force. This force is then harnessed to turn the wheels of your car.

To handle the immense stresses and temperatures of constant combustion, the engine is built to be incredibly strong. It’s fundamentally composed of two main sections:

- Cylinder Block: The heavy, lower portion, often referred to as the engine block, is the foundation. It’s the main housing for the engine’s moving parts, providing structural integrity and support.

- Cylinder Head: This detachable upper section sits atop the cylinder block and is crucial for managing the flow of gases. The cylinder head contains carefully engineered passages and valves that control the entry of the air-fuel mixture into the cylinders and the exit of exhaust gases after combustion.

Within the cylinder block resides the crankshaft, a vital component that acts as a translator of motion. It converts the up-and-down, or reciprocating, motion of pistons into the rotary motion needed to turn the wheels. Often, the cylinder block also houses the camshaft, responsible for orchestrating the precise opening and closing of valves in the cylinder head. In some engine designs, the camshaft might be located in the cylinder head itself or above it.

The Engine’s Symphony: How a Car Engine Works

Think of your car engine as a sophisticated food-to-energy converter, much like your own body. Instead of food, it consumes gasoline (or other fuels) and transforms it into motion. This transformation is called “internal combustion.” Combustion, simply put, is burning – a fundamental chemical reaction that releases energy from a fuel-air mix.

In an internal combustion engine (ICE), this critical ignition and burning process occurs right inside the engine itself. The engine then cleverly converts a portion of the energy released from combustion into useful work.

The basic working unit of the engine is the cylinder, a fixed chamber, and the piston, a moving component within it. When combustion happens, the rapidly expanding gases exert pressure, forcefully pushing the piston. This linear motion of the piston is then transferred to the crankshaft, causing it to rotate. This rotational motion is the key to driving your vehicle’s wheels, achieved through a series of gears in the powertrain system.

Imagine creating a tiny, but powerful explosion in a confined space, like the cylinder and piston in your engine. This explosion releases a tremendous amount of energy as expanding gas. A typical car engine generates these controlled explosions hundreds of times every minute. The engine’s ingenious design captures this energy and uses it to power your car.

These explosions push the pistons within the engine to move. As one explosion’s energy wanes, another ignites, continuing the cycle. This continuous series of explosions drives the pistons, providing the constant power your car needs to move.

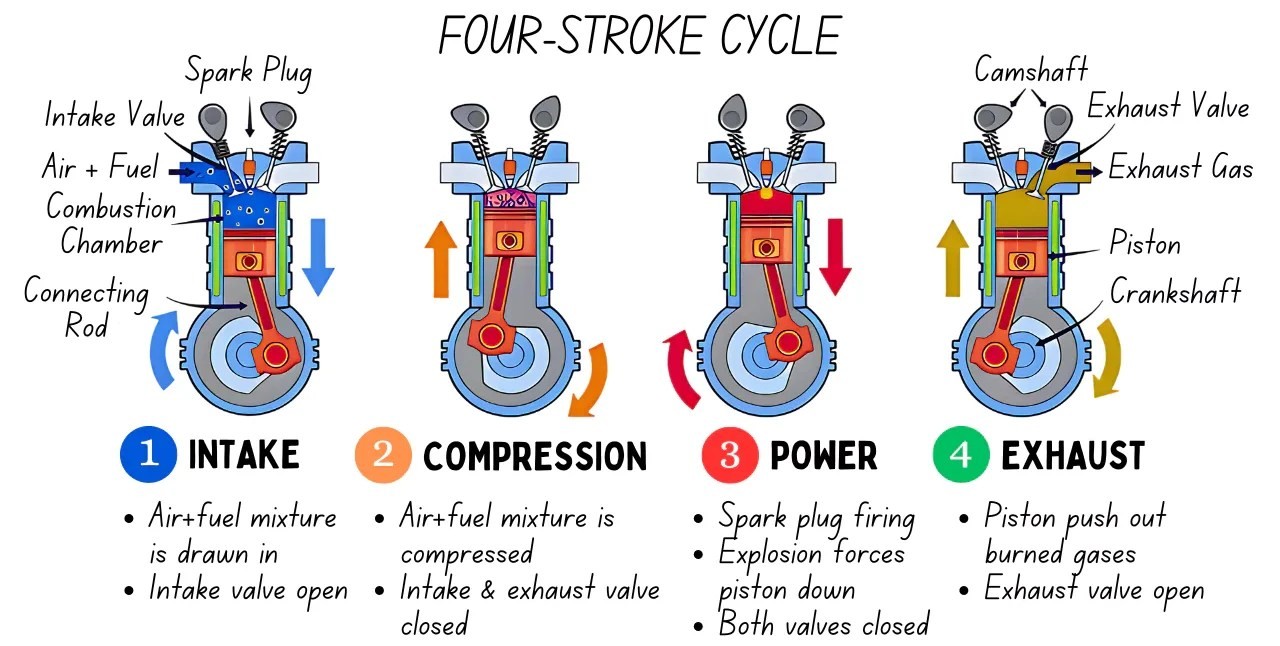

Most car engines operate on a four-stroke combustion cycle. These four strokes – intake, compression, combustion (power), and exhaust – are repeated in a precise sequence to generate power. Let’s break down each stroke:

#1. Intake Stroke

- The piston starts at the top of the cylinder (Top Dead Center or TDC) and moves downwards to the bottom (Bottom Dead Center or BDC).

- During this stroke, the intake valve opens while the exhaust valve remains closed.

- The downward motion of the piston creates a vacuum, drawing the air-fuel mixture into the cylinder through the open intake valve, like inhaling air into your lungs.

#2. Compression Stroke

- The piston now reverses direction, moving upwards from BDC back to TDC.

- Both the intake and exhaust valves are tightly closed.

- As the piston moves up, it compresses the air-fuel mixture within the combustion chamber, significantly increasing its temperature and pressure, preparing it for ignition.

#3. Power Stroke (Combustion Stroke)

- Just before the piston reaches TDC, the spark plug ignites the highly compressed air-fuel mixture with a precisely timed spark.

- This ignition causes rapid combustion, creating a powerful explosion that forces the piston downwards with great force.

- This downward force is transferred to the crankshaft, causing it to rotate and generate the power that ultimately drives the wheels. Both valves remain closed during this powerful stroke.

#4. Exhaust Stroke

- The piston moves upwards again, from BDC to TDC.

- This time, the exhaust valve opens, while the intake valve stays closed.

- The upward movement of the piston pushes the burnt exhaust gases out of the cylinder through the open exhaust valve, clearing the chamber for the next cycle.

- These exhaust gases are then routed through the catalytic converter for cleaning and then out of the vehicle through the muffler and tailpipe.

The precise timing of the intake and exhaust valves opening and closing is controlled by cams on the camshaft. The camshaft, in turn, is driven by a timing belt or chain connected to the engine’s crankshaft, ensuring perfect synchronization of all these moving parts.

In engines with multiple cylinders, the combustion cycles are carefully staggered to ensure smooth power delivery and minimize vibrations and noise. This balanced operation is key to a comfortable and efficient driving experience.

However, it’s important to note that gasoline engines are not perfectly efficient. On average, they convert only about 20% of the fuel’s chemical energy into mechanical energy. Of this, only around 15% actually reaches the wheels to move the car, with the rest lost to friction, heat, and other mechanical inefficiencies. This is why ongoing research and development are focused on improving engine efficiency and exploring alternative fuel sources.

Now that we have a foundational understanding of how a car engine works, let’s dive deeper into the individual components that make this intricate process possible. Understanding these car engine parts names and their roles is crucial for anyone wanting to learn more about their vehicle.

Car Engine Parts Names with Diagram: Visualizing the System

To better understand the location and appearance of these essential components, let’s look at a car engine parts diagram. This visual representation will help you familiarize yourself with the main elements and their positions within the engine.

This diagram highlights many of the crucial car engine parts names we’ll be discussing in detail, including:

- Engine Block

- Combustion Chamber

- Cylinder Head

- Pistons

- Crankshaft

- Camshaft

- Timing Chain/Belt

- Valves

- Rocker Arms

- Pushrods/Lifters

- Fuel Injectors

- Spark Plugs

- Oil Pan

- Distributor (in older engines)

- Connecting Rods

- Piston Rings

- Flywheel

List of Car Engine Parts Names: Essential Components

While the engine might appear as a single unit, it’s actually an assembly of hundreds of parts. However, for a good understanding, focusing on the main components is key.

Here’s a list of some important car engine parts names you should be familiar with:

- Distributor O-ring

- Cylinder Head Cover

- Rubber Grommet

- Camshaft Pulley

- Oil Filter

- Water Pump

- Timing Belt Drive Pulley

- Oil Pan Drain Bolt

- Turbocharger and Supercharger (in some engines)

- Starter Motor

While a typical internal combustion engine can have around 200 parts, modern electric vehicles dramatically reduce this complexity to around 20 moving parts. However, for now, we are focusing on the core components of a traditional car engine.

Parts of A Car Engine: Detailed Exploration

Let’s delve deeper into the function of each of these car engine parts names, providing a more comprehensive understanding of their roles within the engine system.

#1. The Engine Block (Cylinder Block)

The engine block, also known as the cylinder block, is the foundational structure of the engine. It’s the primary housing for the engine’s core components, forming what’s often called the “bottom end” of the engine.

Within the engine block, the crankshaft rotates, and the pistons move up and down inside cylindrical bores. These pistons are driven by the force of fuel combustion. In some engine designs, the engine block also provides housing for the camshaft.

Modern engine blocks are commonly made from aluminum for its lightweight properties, contributing to better fuel efficiency. However, older vehicles often used cast iron due to its robustness. The metallic construction of the engine block is crucial for its strength and its ability to efficiently dissipate heat generated by combustion to the cooling system.

The engine block is precisely engineered with numerous passages and holes to accommodate the cylinders and to create pathways for coolant and oil. These pathways are essential for engine cooling and lubrication. Coolant passages are wider than oil passages, reflecting their different roles.

When the cylinder head is bolted to the top of the engine block, it seals the cylinders, allowing the pistons to compress the air-fuel mixture and drive the crankshaft. The oil pan is located at the base of the engine block, serving as a reservoir for engine oil, which is drawn up by the oil pump to lubricate and cool the engine’s moving parts.

Common Symptoms of a Bad Engine Block:

- Poor Engine Performance: Low engine compression due to block damage.

- Visible Engine Smoke: Smoke emanating from the engine area.

- Engine Overheating: Antifreeze leaks from cracks in the block can lead to overheating.

- Discoloration in Oil or Antifreeze: Mixing of fluids due to internal block cracks.

- Leaking Oil or Coolant: External leaks from cracks or damaged seals.

- Frozen Coolant in Radiator: In extreme cases, block damage can lead to coolant freezing within the system.

- Excessive Smoke from Exhaust: Burning coolant or oil due to block issues.

- Low Coolant Levels: Consistent coolant loss without external leaks, suggesting internal leakage into the engine.

#2. The Piston

Pistons are cylindrical components that move up and down within the cylinders. Their primary function is to convert the pressure created by the burning air-fuel mixture into a mechanical force that acts upon the crankshaft.

The design of a piston is closely related to the type of internal combustion engine. Gasoline engine pistons are typically lighter and shorter than those in diesel engines due to the different combustion processes and pressures involved.

Each piston is connected to the crankshaft via a connecting rod. The connection between the piston and connecting rod is made by a wrist pin (or gudgeon pin), a short hollow tube that bears the full force of combustion. This assembly – piston, connecting rod, and wrist pin – is known as the piston assembly.

To maintain a tight seal and prevent leakage, piston rings are fitted into grooves around the piston’s circumference. These rings bridge the narrow gap between the piston and the cylinder wall, ensuring compression and preventing oil from entering the combustion chamber. The areas between these ring grooves are called ring lands.

Pistons endure incredible stress and speed. In a typical engine, pistons move up and down twice for every crankshaft revolution. At an engine speed of 1300 RPM, pistons can travel up and down 2600 times per minute!

Functions Performed by the Piston:

- Heat Dissipation: Helps transfer heat away from the combustion chamber.

- Combustion Chamber Sealing: Creates a seal to prevent gas leakage and oil contamination of the combustion chamber.

- Connecting Rod Guidance: Guides the movement of the connecting rod.

- Gas Exchange: Facilitates continuous gas exchange within the combustion chamber.

- Variable Volume Creation: Creates the changing volume within the combustion chamber necessary for the four-stroke cycle.

Most Common Symptoms for Bad Piston:

- White or Gray Exhaust Smoke: Indicates oil burning in the combustion chamber due to piston or ring damage.

- Excessive Oil Consumption: Oil leaking past damaged pistons or rings.

- Low Power for Acceleration: Reduced compression and inefficient combustion.

- Overall Loss of Power or Poor Performance: General engine weakness and reduced responsiveness.

#3. The Crankshaft

The crankshaft is often considered the backbone of the internal combustion engine. It’s the central rotating shaft that converts the linear, reciprocating motion of the pistons into rotary motion, the kind needed to power your car’s wheels.

It takes the force generated by the pistons’ up-and-down movement and transforms it into the rotational energy that ultimately propels your vehicle. The crankshaft is housed within the crankcase, located beneath the engine block.

Crankshafts are typically forged from steel due to steel’s exceptional strength and durability, necessary to withstand the high stresses and rotational forces within the engine. They are usually designed as a single piece for maximum strength and to minimize vibration, given their high rotational speeds.

The crankshaft is supported at both ends by large bearings within the engine block. It’s connected to the flywheel, which, in turn, connects to the clutch (in manual transmissions) or torque converter (in automatic transmissions).

When the clutch is engaged, the crankshaft’s rotational energy is transmitted through the gearbox (transmission) and then to the differential, finally reaching the drive shafts that turn the wheels. This chain of components allows the engine’s power to be effectively transferred to the road.

Symptoms of a Bad or Failing Crankshaft Position Sensor (Note: Not the Crankshaft Itself, but a Related Sensor):

- Issues Starting the Vehicle: Sensor failure can disrupt ignition timing.

- Intermittent Stalling: Erratic sensor readings can cause the engine to stall unexpectedly.

- Check Engine Light Comes On: Sensor malfunction triggers the engine management system to illuminate the warning light.

- Uneven Acceleration: Inconsistent engine performance due to incorrect timing information.

- Engine Misfires or Vibrates: Improper combustion due to timing issues.

- Rough Idle and/or Vibrating Engine: Unstable engine operation at idle speed.

- Reduced Gas Mileage: Inefficient engine operation due to timing problems.

#4. The Camshaft

A camshaft is a seemingly simple but critically important engine component. It’s essentially a rotating shaft with strategically shaped protrusions called cams or cam lobes.

As the camshaft rotates, these cams actuate the engine’s valves, precisely controlling when they open and close. The shape of the cams determines how far and how quickly the valves open, and the camshaft’s rotation speed governs the valve timing.

In modern engines, camshafts are typically located above the cylinder banks, directly acting on the valves. Their precise calibration is essential for optimal engine performance. They control the amount of air-fuel mixture entering the combustion chamber and the efficient expulsion of exhaust gases.

The camshaft’s timing is directly linked to the crankshaft’s rotation via a timing belt or chain. This synchronization ensures that the valves open and close at precisely the right moments in relation to the piston’s movement. The shape of the cams and the camshaft’s timing are crucial factors in engine performance and efficiency.

Camshafts, like other critical engine parts, are made from strong metals like chilled iron to withstand the demanding conditions within the engine.

Symptoms of a Bad Camshaft:

- Active or Flashing Check Engine Light: Camshaft issues can trigger sensor warnings.

- Loss of Power: Incorrect valve timing reduces engine efficiency and power output.

- Steady Popping/Backfire in Intake or Exhaust: Extreme cam wear can cause valve timing to be severely off.

- Loud Ticking or Tapping Sounds: Worn cam lobes or lifters can create noise.

- Metal Debris in Engine Oil: Camshaft wear can shed metal particles into the oil.

- Cylinder Misfire: Incorrect valve operation can lead to misfires.

- Increased Emissions: Misfiring and inefficient combustion increase exhaust pollutants.

- Visible Signs of Damage: Upon inspection, worn or damaged cams may be visible.

#5. The Connecting Rod

As its name implies, a connecting rod is a vital link, connecting the piston to the crankshaft. These rods are typically made of strong materials like steel or aluminum, chosen for their ability to withstand high tensile and compressive forces.

The connecting rod, often called a “con rod,” works in conjunction with the crankshaft to convert the piston’s linear (up-and-down) motion into the crankshaft’s rotary motion.

The end of the connecting rod that attaches to the piston is called the small end, while the end that encircles the crankshaft is the big end. The big end is fitted with bearing inserts to minimize friction and maintain precise oil clearance with the crankshaft journal.

The big end of the connecting rod is split and held together by a connecting rod cap, which clamps the bearing inserts and the crankshaft journal securely.

The connecting rod is designed to transmit both compressive and tensile forces from the piston. Its pivoting design at the piston end and rotating design at the crankshaft end are crucial for smooth engine operation.

Many connecting rods have an internal oil passage that runs from the big end up to an outlet near the small end. This passage allows oil to be sprayed onto the cylinder wall, providing crucial lubrication in the high-pressure area where friction is greatest.

Symptoms of a Bad Connecting Rod:

- Low Compression: Bent or damaged rods can affect piston movement and cylinder sealing.

- Engine Knocking Sounds (Rod Knock): Worn or damaged rod bearings create a distinct knocking noise, especially under load.

- Low Oil or Oil Pressure: Rod bearing failure can restrict oil flow and reduce pressure.

- Visibly Bent or Damaged Rod: Upon engine disassembly, physical damage to the rod may be apparent.

- Seized Engine: In severe cases, rod failure can cause catastrophic engine seizure.

#6. Timing Belts

The timing belt is a critical component that ensures the synchronized operation of many engine parts. It’s essential for the engine’s combustion cycle and overall efficiency.

The timing belt connects the crankshaft and camshaft, coordinating their rotation. The crankshaft’s rotation is dictated by piston movement, while the camshaft controls the intake and exhaust valves. The timing belt ensures that the valves open and close at precisely the right time relative to the piston’s position, preventing collisions and ensuring proper combustion.

Modern timing belts are typically made of durable synthetic rubbers like neoprene or highly saturated nitrile, reinforced with high-tensile cords made of Kevlar, polyester, or fiberglass. This construction allows them to withstand high temperatures and stresses.

However, timing belts are subject to wear and tear over time and mileage. It’s generally recommended to replace them every 60,000 to 100,000 miles, or as specified by the vehicle manufacturer.

A worn timing belt can slip, leading to engine misfires and performance issues. Unfortunately, timing belt failure is often sudden and catastrophic, rather than a gradual decline. When a timing belt breaks, the engine can stop immediately or lose significant power.

Symptoms of a Bad Timing Belt:

- A Ticking Noise from the Engine: A worn belt may produce a ticking or slapping sound.

- The Engine Won’t Turn Over: A broken timing belt prevents the camshaft from turning, halting engine operation.

- The Engine Acts Up Between 2,000 – 4,000 RPM: Slipping belts can cause misfires and performance issues at specific RPM ranges.

- The Engine Misfires: Incorrect valve timing due to a slipping belt leads to misfires.

- More Smoke and Fumes Than Normal: Inefficient combustion can increase exhaust emissions.

- Oil Leaks from the Front of the Motor: Less common, but sometimes timing belt cover leaks can be associated with belt issues.

#7. Spark Plugs

Spark plugs are essential components in gasoline engines, located above each cylinder. They are responsible for initiating combustion by igniting the air-fuel mixture.

The spark plug’s function is to convert high-voltage electricity, generated by the ignition coil, into a spark within the combustion chamber. This spark ignites the compressed air-fuel mixture just before the power stroke.

A spark plug consists of a threaded metal shell electrically insulated from a central electrode by a ceramic insulator. The central electrode is connected to the ignition coil by a heavily insulated wire. The metal housing is grounded to the cylinder head.

The center electrode protrudes into the combustion chamber, creating a spark gap between itself and one or more side electrodes attached to the threaded jacket. When high voltage is applied, a spark jumps across this gap, igniting the air-fuel mixture.

Spark plugs are consumable items and degrade over time due to wear, combustion byproducts, and electrical stress. They can become “fouled” with carbon deposits, contamination, or overheat, losing their ability to ignite the mixture effectively and conduct heat away from the combustion chamber.

Symptoms of Bad Spark Plugs:

- Reduced Gas Mileage: Inefficient combustion wastes fuel.

- Lack of Acceleration: Misfires and weak combustion reduce engine power.

- Hard Starts: Weak spark makes it difficult to ignite the air-fuel mixture, especially when cold.

- Engine Misfires: Incomplete or failed combustion in one or more cylinders.

- Rough Idling: Uneven combustion causes engine vibrations and rough idle.

#8. Cylinder Head

The cylinder head sits atop the engine block, sealing the top of the cylinders and forming the combustion chambers. It’s a critical component that manages airflow, fuel delivery, and combustion.

Cylinder heads must be incredibly robust to withstand immense pressures and high temperatures while maintaining a perfect seal with the engine block via the head gasket. They contain numerous integrated features, including:

- Intake and Exhaust Ports: Passages for air-fuel mixture entry and exhaust gas exit.

- Coolant Passages: Channels for coolant circulation to regulate temperature.

- Valves: Control the opening and closing of intake and exhaust ports.

- Camshafts (in some designs): Actuate the valves.

- Spark Plugs (in gasoline engines): Provide ignition.

- Fuel Injectors (in many engines): Spray fuel into the intake ports or cylinders.

Cylinder heads are typically made from either cast iron or aluminum. Cast iron heads are more durable and less expensive but are heavier and less efficient at dissipating heat. Aluminum cylinder heads are lighter and offer better heat dissipation, making them common in performance engines.

The most common cause of cylinder head failure is overheating, often due to coolant loss, head gasket failure, or restricted coolant flow. Overheating can lead to warping or cracking of the cylinder head.

In severe cases, a cracked or damaged cylinder head can cause irreparable damage to the entire engine. Prompt attention to any cylinder head issues is crucial to prevent major engine problems.

Symptoms of a Cracked Cylinder Head:

- White Smoke (Steam) From the Exhaust Pipe: Coolant leaking into the combustion chamber and burning.

- Low Coolant Level: Coolant loss due to leakage.

- Engine Overheating: Coolant loss and compromised cooling system efficiency.

- Rough Running and Misfiring: Coolant or compression leaks affect combustion.

- Combustion Gases in the Cooling System: Pressure from combustion leaking into the coolant system.

- Illuminated Warning Lights: Overheating or other issues trigger warning lights.

- Coolant-Oil Intermix: Mixing of coolant and oil due to internal cracks, often appearing as milky oil.

#9. The Oil Pan

The oil pan is located at the bottom of the engine and serves as the reservoir for engine oil. It’s bolted to the underside of the engine block and is essential for the engine’s lubrication system.

Engine oil is pumped from the oil pan throughout the engine to lubricate, clean, and cool moving parts. After circulating through the engine, the oil drains back into the oil pan, completing the cycle.

The oil pan is typically made of steel or aluminum and can hold between four to six liters of oil, depending on the engine size. The oil dipstick extends into the oil pan to allow for manual oil level checks. A drain plug at the bottom of the oil pan allows for easy oil draining during oil changes.

Regularly checking your engine oil level and maintaining proper oil change intervals is crucial for engine health and longevity.

Symptoms of a Bad Oil Pan:

- The Low Oil Warning Light Comes On: Indicates low oil level, possibly due to a leak.

- You See a Puddle of Oil Under Your Car: A clear sign of an oil leak, potentially from a damaged oil pan.

- Your Oil Level Has Dropped Unexpectedly: Rapid oil loss suggests a leak.

- Your Engine is Overheating: Low oil level and reduced lubrication can lead to overheating.

- You Notice a Burning Smell Coming from the Engine: Oil leaking onto hot engine components can cause a burning smell.

#10. Engine Valves

Engine valves are mechanical components that control the flow of air-fuel mixture into and exhaust gases out of the combustion chambers (cylinders). They are crucial for the four-stroke combustion cycle.

There are two main types of engine valves:

- Intake Valves: Allow the air-fuel mixture to enter the combustion chamber during the intake stroke.

- Exhaust Valves: Allow exhaust gases to exit the combustion chamber during the exhaust stroke.

Valves operate mechanically, typically actuated by rocker arms that are moved by cams on the camshaft. They open and close in a precise sequence and timing, synchronized with the piston movement.

The movement of the valves is controlled by pear-shaped cams on the rotating camshaft, which is driven by the crankshaft via a timing belt or chain or gears.

In overhead valve (OHV) engines, tappets and pushrods transmit the cam’s motion to rocker arms, which then actuate the valves. In overhead camshaft (OHC) engines, the camshafts are located in the cylinder head and directly actuate the valves, eliminating pushrods.

Valves are held closed by strong valve springs. When a cam lobe pushes on the rocker arm (or directly on the valve in OHC engines), it overcomes the spring pressure and opens the valve. As the camshaft rotates further, the spring force closes the valve again.

The Symptoms of Bad Valves Include:

- Cold Engine Issues: Valve problems can be more pronounced when the engine is cold.

- Off-Throttle Braking Problems: Poor valve sealing can affect engine braking.

- Idling Issues: Uneven valve operation leads to rough idling.

- Excessive Oil Consumption: Worn valve seals can allow oil to leak into the combustion chamber.

- Excessive Smoke: Burning oil due to valve seal leaks results in blue exhaust smoke.

- Loss of Engine Power: Improper valve operation reduces engine efficiency and power.

#11. Combustion Chamber

The combustion chamber is the enclosed space within the cylinder where the air-fuel mixture is burned. It’s formed by the cylinder, piston, and cylinder head.

The primary function of the combustion chamber is to contain the combustion process and harness the energy released. The piston compresses the air-fuel mixture, and the spark plug ignites it. The resulting combustion generates high-pressure, high-temperature gases that push the piston, producing power.

The size of the combustion chamber is defined as the volume above the piston when it’s at Top Dead Center (TDC) and both valves are closed. A smaller combustion chamber results in a higher compression ratio, which generally leads to increased power and efficiency but also higher temperatures.

The combustion chamber’s size and shape are crucial factors in engine performance and efficiency. Designers can modify these aspects by altering the cylinder head design or piston crown shape.

What happens if oil gets into the combustion chamber? Oil in the combustion chamber burns, producing blue-gray exhaust smoke. This can occur due to worn valve seals or piston rings, allowing oil to leak into the cylinders. Worn valve seals often cause oil to seep into the cylinders overnight, leading to blue smoke upon cold startup.

#12. Intake Manifold

The intake manifold is a component that distributes air to the engine’s cylinders. In many modern cars, it also houses the fuel injectors.

The intake manifold is responsible for channeling air into the combustion chambers during the intake stroke. This air is then mixed with fuel from the injectors, forming the air-fuel mixture that is combusted.

Air enters the intake manifold after passing through the air filter and throttle body. The intake manifold consists of two main parts:

- Plenum: A chamber that receives air from the throttle body.

- Runners: Tubes that distribute air from the plenum to each cylinder.

The design of the intake manifold, including the plenum size and runner length and diameter, significantly affects engine performance. Modern engines often utilize variable intake manifolds to optimize airflow at different engine speeds.

While intake manifold problems are relatively uncommon, some diesel engines have swirl flaps within the intake ports. These flaps are designed to improve airflow at low engine speeds but can become clogged with exhaust gas recirculation (EGR) deposits, potentially sticking or breaking off and causing engine damage.

Symptoms Of A Bad Intake Manifold:

- Check Engine Light: Vacuum leaks or airflow issues can trigger the warning light.

- Misfires: Uneven air distribution can cause misfires in certain cylinders.

- Rough Idle: Vacuum leaks disrupt smooth engine operation at idle.

- Loss in Engine Performance: Restricted or uneven airflow reduces power.

- External Coolant Leaks: Some intake manifolds have coolant passages and can leak.

- Engine Overheating: Coolant leaks can lead to overheating.

#13. Exhaust Manifold

The exhaust manifold is the first component of the exhaust system. It collects exhaust gases from multiple cylinders and channels them into a single pipe. It’s attached to the cylinder head with gaskets to prevent leaks.

The exhaust manifold’s primary function is to efficiently remove hot exhaust gases from the engine cylinders and direct them towards the catalytic converter for emissions treatment.

In turbocharged engines, the turbocharger is often mounted directly to the exhaust manifold, utilizing the exhaust gas energy to drive the turbine.

Exhaust manifolds are typically made from tubular steel, stainless steel, or cast iron, chosen for their heat resistance and durability.

The exhaust manifold operates at very high temperatures, not only removing burned gases but also promoting further combustion of any unburned or partially burned fuel in the exhaust stream. It also often houses the oxygen sensor, which monitors the oxygen content in the exhaust gas.

The oxygen sensor provides feedback to the engine management system, allowing it to adjust the air-fuel mixture for optimal combustion and emissions control.

Leaks in the exhaust manifold or its gaskets can allow exhaust gases to escape, posing a health hazard to vehicle occupants and potentially causing erroneous oxygen sensor readings, triggering the check engine light. Larger leaks will also produce loud exhaust noises.

Symptoms of a Cracked or Bad Exhaust Manifold:

- Check Engine Light Will Turn On: Oxygen sensor readings can be affected by leaks.

- Burning Smells: Exhaust leaks can introduce hot gases and odors into the cabin.

- Performance Problems or Sluggish Acceleration: Exhaust leaks can disrupt engine backpressure and performance.

- Poor Fuel Economy: Inefficient combustion due to exhaust leaks.

- Loud Exhaust Noise: Cracks or leaks create noticeable exhaust noise.

- Visible Damage: Cracks or corrosion may be visible on the manifold itself.

#14. Piston Ring

A piston ring is a split metallic ring that fits into a groove on the outer diameter of a piston. Each piston typically has multiple piston rings.

Piston rings are usually made of cast iron and are designed to create a seal between the piston and the cylinder wall.

While essential, piston ring movement within the cylinder wall creates friction, which accounts for a significant portion of engine’s mechanical losses.

Piston rings have four primary functions:

- Compression Gas Sealing: Prevent combustion gases from leaking past the piston into the crankcase, maintaining cylinder pressure.

- Oil Control: Scrape excess oil from the cylinder walls back into the crankcase, preventing oil from entering the combustion chamber and minimizing oil consumption.

- Heat Transfer: Transfer heat from the piston to the cooler cylinder walls and engine block, helping to cool the piston.

- Wear Control: Distribute wear evenly between the piston and cylinder wall, extending component life.

Car engines typically use three piston rings per cylinder. The top two rings, called compression rings, primarily focus on sealing combustion gases. The lower ring, known as the oil scraper ring, controls oil consumption.

Symptoms of Bad Piston Rings:

- Discolored or Excessive Exhaust (Blue Smoke): Oil burning due to oil leaking past worn rings.

- Oil Leaks or Profuse Oil Consumption: Oil bypassing worn rings and entering the combustion chamber.

- Declining Engine Performance: Reduced compression and inefficient combustion.

- Low Acceleration: Loss of power due to compression leaks.

- Oil in the Intake Manifold: Blow-by gases carrying oil can enter the intake system.

#15. Gudgeon Pin (Wrist Pin)

A gudgeon pin, also known as a wrist pin, is a crucial connector in the piston assembly. It joins the piston to the connecting rod, allowing the connecting rod to pivot as the piston moves within the cylinder.

The piston pin is typically a short, hollow, forged rod made from high-strength, hardened alloy steel. It may be designed to float freely within both the piston and connecting rod or be fixed in one or both components.

The ends of the pin are chamfered for smooth installation, and it’s secured within the piston, with the small end of the connecting rod fitting around its center.

#16. Cam

A cam is a shaped component, typically part of a camshaft, used to convert rotary motion into linear motion or vice-versa.

In an engine, cams on the camshaft are used to actuate the valves. As the camshaft rotates, the shape of the cams causes them to push on valve lifters or rocker arms, opening the valves at specific times and durations.

The shape and profile of the cams are critical for engine performance. They determine valve timing, lift, and duration, which directly impact engine power, torque, and efficiency.

A worn or damaged cam can disrupt valve timing and performance, leading to various engine problems.

#17. Flywheel

The flywheel is a heavy, rotating disc attached to the end of the crankshaft. It’s typically made from cast iron or steel for its mass and durability.

The flywheel’s primary function is to smooth out the engine’s power delivery. Combustion in an engine is a series of pulses, not a continuous force. The flywheel’s inertia stores energy during the power stroke and releases it during other strokes, creating smoother crankshaft rotation.

It also provides momentum for the compression stroke and helps the engine start more easily by providing initial rotational energy. Without a flywheel, engines would run much rougher and be harder to start.

The flywheel also contributes to engine balance and reduces vibrations and noise generated during combustion.

Symptoms of a Bad Flywheel:

- Slipping Gears: Flywheel issues can affect clutch engagement in manual transmissions.

- Cannot Change Gears: Difficulty shifting gears.

- Burning Odor: Overheated clutch due to flywheel problems can produce a burning smell.

- Vibrations of the Clutch (Clutch Chatter): Uneven flywheel surface can cause clutch vibrations.

- Unable to Start, or Inconsistent Starts: Flywheel damage can hinder starter engagement.

- Engine Stalling: Inconsistent flywheel rotation can lead to engine stalling.

- Engine Vibrations with Clutch Engaged: Vibrations transmitted through the drivetrain.

#18. Head Gasket

The head gasket is a crucial sealing component located between the engine block and the cylinder head(s). It ensures a leak-proof seal under extreme pressure and temperature.

The head gasket’s main function is to seal the combustion chambers, preventing combustion gases from escaping and preventing coolant or engine oil from leaking into the cylinders or mixing with each other. A compromised head gasket can lead to serious engine problems.

Modern head gaskets are often made from multi-layered steel (MLS) for increased durability and sealing performance. They are designed to withstand high temperatures and pressures and maintain a reliable seal over the engine’s lifespan.

Signs Your Head Gasket Is Blown:

- Engine Overheating: Loss of coolant and combustion gas leaks can cause overheating.

- White Smoke from Tailpipe: Coolant leaking into the combustion chamber and burning.

- Low Coolant Level: Coolant loss due to leakage.

- Rough Idle/Engine Knock: Compression leaks and coolant entry disrupt combustion.

- Contaminated Engine Oil (Milky Oil): Coolant mixing with oil creates a milky, frothy appearance.

#19. Cylinder Liner (Sleeve)

A cylinder liner, also known as a cylinder sleeve, is a replaceable, thin-walled cylinder inserted into the engine block’s cylinder bore. It provides a wear-resistant surface for the piston to move within.

The cylinder liner becomes the actual working surface of the cylinder, protecting the engine block from wear, heat, and corrosion. It’s designed to be replaceable, allowing for engine rebuilding without replacing the entire engine block.

Cylinder liners are typically made from cast iron alloys with additions of nickel, chromium, molybdenum, vanadium, or other elements to enhance wear resistance and oil retention.

There are three main types of cylinder liners:

- Wet Liners: In direct contact with engine coolant, providing excellent heat transfer.

- Dry Liners: Press-fit into the cylinder block and not directly exposed to coolant.

- Hot Liners: Used in air-cooled engines and made of heat-dissipating materials.

Regular inspection of cylinder liners for cracks, scoring, or wear is important during engine maintenance. Damage or wear necessitates liner replacement.

#20. Crankcase

The crankcase is the main housing of the engine, enclosing the crankshaft, pistons, cylinders, and connecting rods. It’s the central structural component to which other engine parts and accessories are attached.

The crankcase provides structural support for the engine and houses the rotating and reciprocating components. It also contains oil and coolant passages for lubrication and cooling.

The crankcase is typically a complex casting, often made from aluminum or cast iron, due to the intricate internal passages and structural requirements.

In older engine designs, “open crank” engines lacked a crankcase, but modern engines universally utilize enclosed crankcases for strength, lubrication containment, and noise reduction.

Crankcase pressure can be monitored to diagnose potential engine problems, such as piston ring blow-by or PCV system malfunctions.

#21. Engine Distributor (Older Engines)

The engine distributor is an ignition system component used in older vehicles. It’s responsible for distributing high-voltage sparks to each spark plug in the correct firing order and timing.

The distributor receives high voltage from the ignition coil and uses a rotating rotor and distributor cap to sequentially route this voltage to each spark plug wire.

As the distributor rotor spins, it aligns with terminals in the distributor cap, sending a spark to the corresponding spark plug. This precise distribution of sparks is essential for proper engine operation.

Distributors are less common in modern vehicles, which typically use distributorless ignition systems with individual ignition coils for each cylinder.

Symptoms of a Bad Engine Distributor (Older Engines):

- Your Car Won’t Start: Distributor failure prevents spark delivery.

- Engine Keeps Misfiring or Backfiring: Erratic spark distribution.

- Your Car is Shaking: Misfires cause engine vibrations.

- Check Engine Light Comes On: Ignition system faults can trigger the warning light.

- High-Pitched Noise from Under the Hood: Distributor bearing wear can create noise.

- Failed Emissions Test: Misfires and inefficient combustion increase emissions.

#22. Distributor O-ring (Older Engines)

The distributor O-ring is a small rubber seal that prevents oil leaks and maintains the distributor’s position. It’s relevant in older vehicles with distributors.

The distributor O-ring seals the distributor housing to the engine block, preventing oil from leaking out and contaminants from entering. It also helps maintain the distributor’s precise alignment, which is critical for ignition timing.

Over time, the O-ring can degrade due to heat, oil exposure, and age, leading to oil leaks and potential ignition timing issues.

Symptoms of a Bad or Failing Distributor O-ring (Older Engines):

- Oil Leaking from the Base of the Distributor: Visible oil leak at the distributor base.

- Lack of Power: Oil contamination or timing issues can affect performance.

- The Engine Running Rough: Misfires or timing problems can cause rough running.

- Engine Misfire: Timing inaccuracies due to distributor movement.

#23. Cylinder Head Cover (Valve Cover)

The cylinder head cover, also known as the valve cover, seals the top of the cylinder head. It’s typically made from cast iron or aluminum alloy.

The cylinder head cover’s primary function is to seal the cylinder head, preventing oil leaks and protecting the valvetrain components (valves, rocker arms, camshaft, etc.) from dirt and debris.

It also helps contain oil splash and mist within the valvetrain area for proper lubrication.

#24. Rubber Grommet

Rubber grommets are small, flexible rings used to protect wires, tubes, or hoses as they pass through holes in engine components or body panels.

Grommets prevent abrasion and damage to wiring or lines caused by sharp edges of holes. They also provide a degree of sealing against dust and moisture ingress.

#25. Oil Filter

The oil filter is a crucial component in the lubrication system. It removes contaminants from the engine oil, keeping it clean and effective.

As engine oil circulates, it picks up dirt, metal particles, and combustion byproducts. The oil filter traps these contaminants, preventing them from circulating and causing wear within the engine.

Oil filters are typically cylindrical canisters containing filter media made of synthetic fibers or paper. Oil is forced through the filter media, trapping contaminants before returning to the engine.

Regular oil filter changes, typically with every oil change or every other oil change, are essential for maintaining clean engine oil and engine health.

#26. Camshaft Pulley

A camshaft pulley is a toothed wheel attached to the camshaft. It’s part of the timing system, driven by the timing belt or chain.

The camshaft pulley’s function is to transmit rotational force from the timing belt or chain to the camshaft, causing it to rotate in synchronization with the crankshaft.

The teeth on the pulley mesh with the timing belt or chain, ensuring precise timing of camshaft rotation and valve actuation.

#27. Timing Belt Drive Pulley (Crankshaft Pulley)

The timing belt drive pulley, often referred to as the crankshaft pulley, is a toothed pulley attached to the crankshaft. It drives the timing belt or chain.

The crankshaft pulley transmits rotational force from the crankshaft to the timing belt or chain, which in turn drives the camshaft pulley(s). This system synchronizes crankshaft and camshaft rotation for proper valve timing.

#28. Water Pump

The water pump is a vital component of the cooling system. It circulates coolant throughout the engine and radiator to regulate engine temperature.

The water pump is typically belt-driven by the crankshaft pulley or timing belt. It uses an impeller to pump coolant through the engine block, cylinder head, radiator, and hoses, removing heat from the engine and preventing overheating.

Water pump failure can lead to serious engine overheating and damage.

Common Causes of Water Pump Failure:

- Contaminated Coolant: Debris in coolant can damage pump seals and bearings.

- Mixed Coolant Types: Incompatible coolants can cause corrosion and damage.

- Cavitation: Vapor bubbles in coolant can erode pump components.

Symptoms of a Failing Water Pump:

- Leaking Coolant: Coolant leaks from the pump seal.

- Overheating Engine: Reduced coolant circulation causes overheating.

- Coolant Leaks into the Oil: Internal pump seal failure can allow coolant to mix with oil.

- Engine Noise (Whining, Grinding): Worn pump bearings can create noise.

#29. Turbocharger and Supercharger (Forced Induction)

Turbochargers and superchargers are forced induction devices that increase engine power by compressing intake air. They are not present in all engines, but are becoming more common for improving efficiency and power output.

- Turbocharger: Driven by exhaust gas energy. Exhaust gases spin a turbine, which in turn drives a compressor to force more air into the engine.

- Supercharger: Mechanically driven by the engine, typically via a belt connected to the crankshaft.

Both turbochargers and superchargers increase the amount of air entering the cylinders, allowing more fuel to be burned and generating more power.

The symptoms of a damaged or failing turbo:

- Loss of Power: Reduced boost pressure leads to power loss.

- Slower, Louder Acceleration: Lagging turbo response.

- Difficulty Maintaining High Speeds: Insufficient boost at higher speeds.

- Blue/Grey Smoke from Exhaust: Oil leaks into the turbocharger and burns.

- Check Engine Light: Turbocharger malfunctions can trigger fault codes.

Symptoms of a bad supercharger:

- Ticking Sound from the Motor: Supercharger bearing wear can create noise.

- Decreased Fuel Efficiency: Inefficient supercharger operation.

- Immediate Loss of Power: Supercharger malfunction.

#30. Oil Pan Drain Bolt

The oil pan drain bolt (or plug) is a threaded bolt located at the bottom of the oil pan. It’s removed to drain engine oil during oil changes.

The drain bolt seals the oil pan drain hole, preventing oil leaks. It’s typically fitted with a gasket or crush washer to ensure a leak-proof seal.

A worn or damaged drain bolt or gasket can cause oil leaks.

Check out some of the most common signs that your oil drain plug is worn out and needs replacing:

- A Puddle of Engine Oil Under Your Car: Oil leak from the drain plug area.

- Visible Damage to the Drain Plug: Stripped threads or damaged bolt head.

- Dropping Oil Level: Oil loss due to a leak.

- Engine Performance Problems: Low oil level can lead to engine damage and performance issues.

#31. The Valvetrain

The valvetrain is the system of components that controls the movement of the engine valves. It includes valves, pushrods, lifters, and rocker arms, and is connected to the cylinder head.

#32. The Rocker Arms

Rocker arms are pivoting levers that transfer motion from the camshaft to the engine valves in overhead valve (OHV) engines. They convert the cam’s rotary motion into linear valve movement.

#33. The Pushrods/Lifters

Pushrods and lifters are used in overhead valve (OHV) engines to transmit motion from the camshaft, located in the engine block, to the rocker arms in the cylinder head. Lifters are positioned between the camshaft and pushrods.

#34. Throttle Body

The throttle body controls the amount of air entering the intake manifold and thus the engine cylinders. It regulates engine power and RPM based on driver input via the accelerator pedal.

#35. The Fuel Injectors

Fuel injectors are precision nozzles that spray fuel into the intake manifold or directly into the cylinders (direct injection). They deliver a precisely measured amount of fuel for efficient combustion.

There are three main types of fuel injection systems:

- Direct Fuel Injection: Fuel injected directly into the combustion chamber.

- Ported Fuel Injection: Fuel injected into the intake port, just before the intake valve.

- Throttle Body Fuel Injection: Fuel injected into the throttle body, mixing with air before entering the intake manifold (older system).

#36. Air Intake System

The air intake system delivers clean air to the engine. It includes the air filter, intake ducts or tubes, and the throttle body.

#37. Air Filter

The air filter removes dust, dirt, and other contaminants from the incoming air before it enters the engine. Clean air is essential for efficient combustion and preventing engine wear.

#38. Fuel Delivery System

The fuel delivery system provides the engine with a constant supply of fuel. It includes the fuel tank, fuel pump, fuel lines, fuel filter, and fuel injectors.

#39. Lubrication System

The lubrication system reduces friction and wear between moving engine parts. It includes the oil pan, oil pump, oil filter, and oil passages throughout the engine.

#40. Cooling System

The cooling system regulates engine temperature, preventing overheating. It includes the radiator, water pump, thermostat, coolant hoses, and coolant.

Common Engine Problems

Even with robust construction, car engine parts can wear down or fail over time. Here are some common engine problems and their symptoms:

- Poor Compression: Loss of power, misfiring, or engine no-start.

- Cracked Engine Block: Overheating, smoke from the engine, coolant leaks.

- Damaged Pistons, Rings, and/or Cylinders: Rattling sounds, blue smoke, rough idle, failed emissions test.

- Broken or Worn Rods, Bearings, & Pins: Tapping or ticking sounds, low oil pressure, metal shavings in oil, rattling acceleration.

Regular maintenance, including oil changes, fluid flushes, and timely replacement of belts and hoses, is crucial for preventing engine problems and ensuring longevity.

Car Engine Parts Video

[Car Engine Parts Video Link – Replace with relevant video link if available]

FAQs

What Is an Engine?

An engine (or motor) is a machine that converts energy into mechanical motion. Modern vehicles primarily use internal combustion engines (ICE) that burn fuel to generate power.

How Does a Car Engine Work?

A car engine uses controlled combustion within cylinders to push pistons, which rotate a crankshaft, ultimately driving the vehicle’s wheels through the powertrain.

What are the different parts of an engine?

Key engine parts include the engine block, cylinder head, pistons, crankshaft, camshaft, valves, spark plugs, fuel injectors, and lubrication and cooling systems.

How many parts are in a car engine?

A typical internal combustion engine has around 200 parts, while electric vehicle motors have significantly fewer, around 20 moving parts.

What Engine Does My Car Have?

You can identify your car’s engine type using the Vehicle Identification Number (VIN), typically found in the owner’s manual or on the driver’s side dashboard. The eighth digit of the VIN usually indicates the engine type.

Understanding car engine parts names and their functions is a valuable step towards becoming a more informed car owner. Regular maintenance and timely repairs, guided by this knowledge, can keep your vehicle running smoothly for years to come. For more expert automotive advice and diagnostic tips, visit cardiagxpert.com, your trusted resource for car care and repair.