Imagine a world where a cracked dashboard trim, a missing fender flare, or a broken headlight mount isn’t a costly trip to the auto shop or a frustrating junkyard hunt. Welcome to the reality of 3D printing for car body parts. Once a futuristic fantasy, using a 3d Printer For Car Body Parts is now a tangible solution for automotive enthusiasts and repair professionals alike. This guide will explore how this technology is changing the game, making car repair more accessible, affordable, and even customizable.

For years, car owners facing broken or missing parts had limited options: expensive dealership replacements, often-unavailable vintage components, or imperfect aftermarket substitutes. But what if you could simply create the exact part you need, on demand? That’s the promise of 3D printing, also known as additive manufacturing. By building parts layer by layer from a digital design, 3D printers are empowering individuals and workshops to produce durable and precise car body parts right in their garage.

This technology isn’t just for complex, internal components. With the right 3D printer for car body parts, you can fabricate a wide range of exterior and interior pieces. Think about replicating intricate trim pieces, designing custom vents, or even producing structural elements like bumper components or headlight housings. The possibilities are vast and expanding as 3D printing technology advances.

Why Choose a 3D Printer for Car Body Parts?

The appeal of using a 3D printer for car body parts stems from several key advantages:

- Cost Savings: Replacing car parts, especially for older or less common vehicles, can be incredibly expensive. 3D printing allows you to produce many parts for the cost of the filament, often significantly cheaper than purchasing replacements.

- Customization and Personalization: Want a unique gauge pod, a personalized shift knob, or aerodynamic enhancements tailored to your car? 3D printing empowers you to design and create bespoke parts that are simply unavailable commercially.

- Repairing the Irreparable: For classic and vintage cars, finding replacement parts can be nearly impossible. A 3D printer for car body parts can be a lifesaver, allowing you to recreate obsolete or rare components, keeping automotive history alive.

- Faster Turnaround: No more waiting for parts to be shipped or dealing with backorders. If you have the design, you can print the part when you need it, minimizing downtime for repairs or modifications.

- Empowerment and DIY: 3D printing puts the power of manufacturing in your hands. It’s a fantastic way to engage with your car on a deeper level, fostering a sense of accomplishment and self-reliance.

Selecting the Right 3D Printer for Car Body Parts

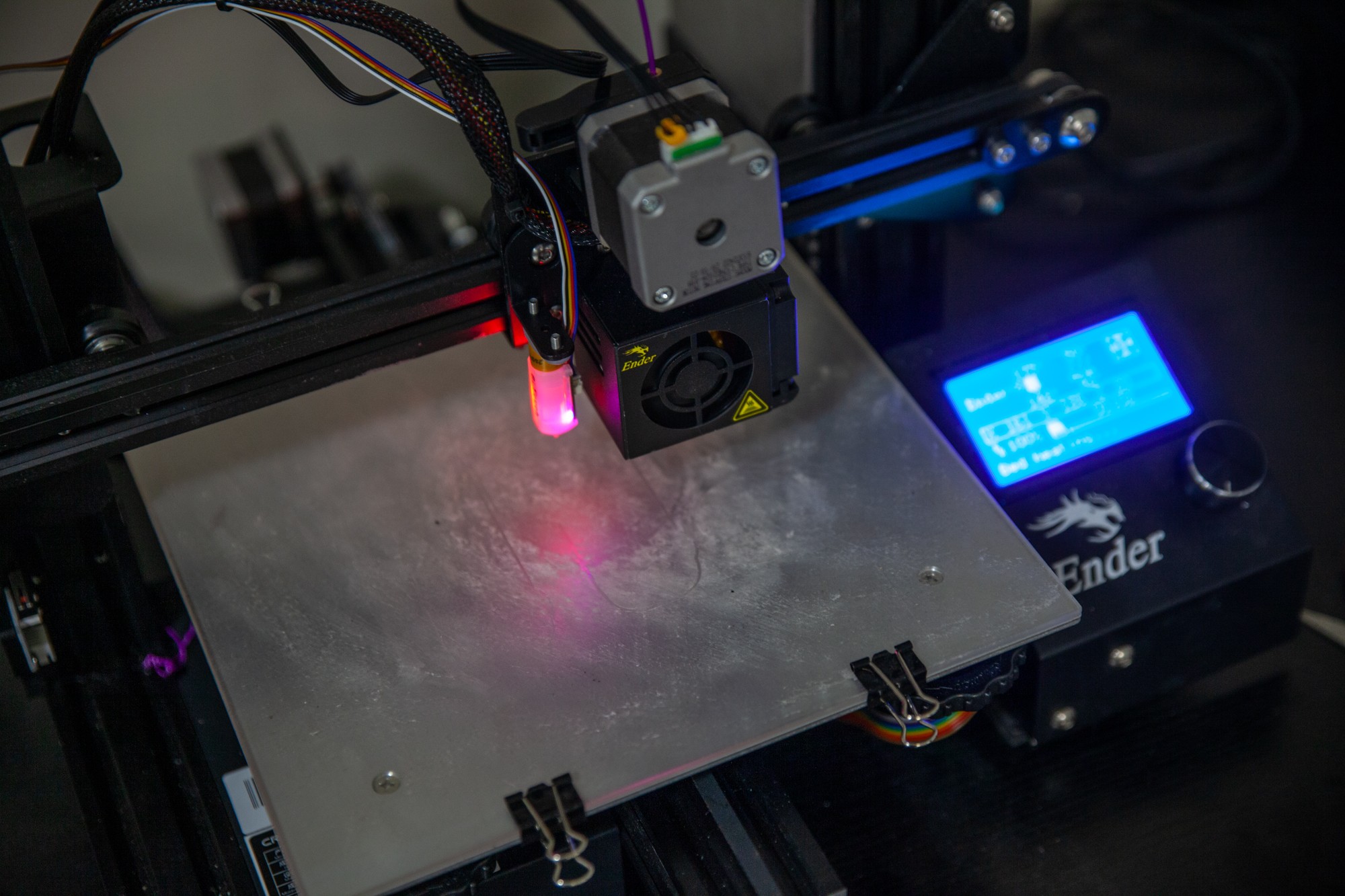

While the idea of printing your own car parts is exciting, choosing the right 3D printer for car body parts is crucial for success. The most common and accessible type for this application is Fused Deposition Modeling (FDM) printing.

FDM 3D Printers: The Go-To for Auto Parts

FDM printers work by melting plastic filament and depositing it layer by layer to build a 3D object. They are relatively affordable, user-friendly, and capable of using a variety of materials suitable for car parts.

Key Considerations When Choosing an FDM 3D Printer for Car Parts:

- Build Volume: Think about the size of the parts you intend to print. Larger parts like bumpers or spoilers will require a printer with a substantial build volume. For smaller interior trim pieces, a smaller, more affordable printer might suffice.

- Print Resolution and Accuracy: For parts that require precise fitment or fine details, look for a printer with good resolution capabilities. Layer height and nozzle size are key specifications to consider.

- Heated Bed: A heated bed is essential for printing with materials like ABS and PETG, which are often preferred for car parts due to their durability and heat resistance. It helps prevent warping and ensures good adhesion of the print to the build surface.

- Enclosure (Optional but Recommended): An enclosure helps maintain a stable printing temperature, especially important when working with materials prone to warping like ABS. It also reduces drafts and fumes, improving print quality and safety.

- Budget: FDM printers range in price from a few hundred to several thousand dollars. Start with a budget-friendly option like the Creality Ender 3 or consider a more feature-rich model like the Prusa MINI+ or Flashforge Finder 3 if your budget allows and you desire a more plug-and-play experience.

Materials Matter: Filaments for 3D Printed Car Parts

The choice of filament is just as important as the printer itself when creating durable and functional car parts. Here’s a look at common filament types and their suitability for automotive applications:

- PLA (Polylactic Acid): Easy to print and affordable, PLA is excellent for prototyping, mock-ups, and interior parts that are not exposed to high heat or direct sunlight. However, its low heat resistance and UV sensitivity make it unsuitable for exterior or under-hood components.

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength, heat resistance, and durability, ABS is a popular choice for automotive parts. It can withstand under-hood temperatures and offers good impact resistance. However, ABS is more challenging to print than PLA, prone to warping, and requires good ventilation due to fumes.

- PETG (Polyethylene Terephthalate Glycol-modified): PETG strikes a balance between PLA and ABS. It’s easier to print than ABS, more durable than PLA, and offers better heat and UV resistance than PLA. PETG is a versatile filament suitable for a wide range of interior and some exterior car parts.

- Advanced Materials (Nylon, Carbon Fiber Composites): For demanding applications requiring exceptional strength, stiffness, and heat resistance, consider advanced filaments like nylon or carbon fiber-reinforced composites. These materials require more advanced printers and printing expertise but can produce parts with performance characteristics comparable to traditional automotive plastics.

From Digital Design to Physical Part: The 3D Printing Workflow

Creating car parts with a 3D printer for car body parts involves a straightforward workflow:

-

Find or Create a 3D Model:

- Online Repositories: Websites like Thingiverse, GrabCAD, and Thangs host vast libraries of free and paid 3D models. Search for parts specific to your car make and model or explore generic designs that can be adapted.

- 3D Modeling Software: If you can’t find a pre-made model, you’ll need to design it yourself using 3D modeling software. Free options like Fusion 360 (for personal use), Tinkercad (beginner-friendly), and Blender (more advanced) are excellent starting points. Learning 3D modeling opens up limitless possibilities for customization and repair.

-

Prepare the Model with Slicing Software: Slicing software converts your 3D model into G-code, a language that your 3D printer understands. Popular slicers like Cura and PrusaSlicer allow you to adjust print settings such as layer height, infill density, print speed, and support structures. These settings determine the quality, strength, and printing time of your part.

-

Print Your Part: Transfer the G-code file to your 3D printer via SD card or USB. Start the print and monitor the process. The printer will then build your car part layer by layer, bringing your digital design to life.

Get Started with 3D Printing Car Body Parts

Using a 3D printer for car body parts is no longer a distant dream, but a practical and increasingly essential tool for automotive enthusiasts and professionals. Whether you’re restoring a classic car, customizing your ride, or simply need to replace a broken piece, 3D printing offers a powerful and versatile solution. With accessible technology, a growing online community, and a wealth of resources, now is the perfect time to explore the exciting world of 3D printed automotive components. Embrace the innovation and unlock a new dimension of auto repair and customization with your own 3D printer for car body parts.