The 2014 C7 Stingray Corvette marked a monumental shift for Chevrolet, redefining modern sports car performance and heralding the return of the legendary Stingray name. This wasn’t just an evolution; it was a revolution. The 2014 Corvette Stingray emerged as a beacon of innovation, masterfully blending cutting-edge technology, breathtaking design, and exhilarating performance into a single, iconic package. This vehicle didn’t just wear the Stingray badge – it embodied its spirit, representing a perfect harmony of elements that elevated the Corvette legacy to new heights.

The 2014 C7 Stingray Corvette was unleashed as the most potent standard Corvette ever produced up to that point. Boasting an estimated 450 horsepower (335 kW) and a formidable 450 lb.-ft. of torque (610 Nm), it delivered raw power with refined control. Beyond brute strength, it was also the most capable standard model, achieving blistering acceleration from 0-60 mph in under four seconds and demonstrating phenomenal cornering grip exceeding 1g. Surprisingly, this powerhouse was also projected to be the most fuel-efficient Corvette, surpassing the EPA-estimated 26 mpg of its predecessor.

The development of the 2014 C7 Stingray Corvette was a ground-up endeavor. Sharing only two parts with the previous generation, it was essentially a clean slate design. An all-new frame structure and chassis formed its foundation, complemented by a brand-new powertrain and a suite of advanced technologies. The exterior and interior designs were completely reimagined, resulting in a vehicle that was both familiar in spirit and strikingly modern in execution. Key highlights of this groundbreaking machine included:

- A meticulously crafted interior: Showcasing genuine carbon fiber, aluminum accents, and hand-wrapped leather surfaces. Drivers could choose between two newly designed seats, each built upon a lightweight magnesium frame for exceptional support. Dual eight-inch configurable screens offered a customizable driver and infotainment experience.

- Advanced driver-centric technologies: The innovative five-position Drive Mode Selector allowed drivers to tailor up to 12 vehicle attributes to match their driving style and environment. A new seven-speed manual transmission with Active Rev Matching ensured seamless gear changes by anticipating selections and precisely matching engine speed.

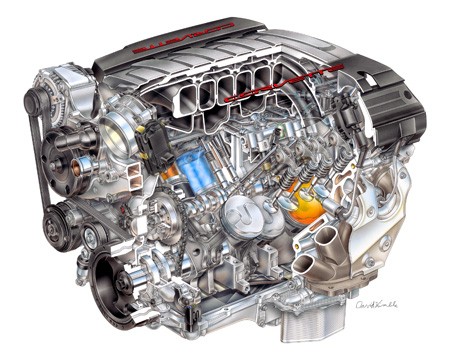

- The heart of the beast – the all-new 6.2L LT1 V-8 engine: This engine incorporated state-of-the-art technologies such as direct injection, Active Fuel Management, continuously variable valve timing, and an advanced combustion system. The result was enhanced power output coupled with improved fuel efficiency.

- Strategic use of lightweight materials: A carbon fiber hood and removable roof panel, composite fenders, doors, and rear quarter panels, carbon-nano composite underbody panels, and a new aluminum frame contributed to an optimal 50/50 weight balance. This weight distribution was crucial for achieving a world-class power-to-weight ratio and exceptional handling.

- Sculpted and aerodynamic exterior: The striking exterior design incorporated advanced high-intensity discharge and LED lighting. Racing-derived aerodynamics balanced low drag for fuel efficiency with performance elements that enhanced stability, particularly at track speeds.

- Track-ready Z51 Performance Package: For those seeking ultimate performance, the Z51 package offered features like an electronic limited-slip differential, dry-sump oiling system, and integral cooling for brakes, differential, and transmission. A unique aero package further amplified high-speed stability.

The birthplace of the 2014 C7 Stingray Corvette was GM’s Bowling Green, Kentucky assembly plant. This facility underwent a significant $131-million upgrade, including a $52 million investment in a new body shop dedicated to in-house manufacturing of the aluminum frame for the first time. Enthusiasts eagerly awaited the arrival of the 2014 Corvette Stingray coupe, which went on sale in the third quarter of 2013, marking the dawn of a new era for the American sports car.

Handcrafted, High-Tech Interior: A Driver-Focused Sanctuary

The interior of the 2014 C7 Stingray Corvette was designed as a harmonious blend of premium materials, meticulous craftsmanship, and advanced technologies. This fusion created a driving environment that was both luxurious and intensely focused on the driver’s experience. According to Helen Emsley, Interior Design Director, the goal was to craft an interior that fostered a “more connected and more engaging driving experience.”

Premium materials were generously employed throughout the cabin. Genuine aluminum trim and available carbon fiber accents highlighted the performance-oriented nature of the car, while adding a touch of sophisticated elegance.

The smaller diameter steering wheel, measuring just 14.1 inches (360 mm), was a key element in enhancing the driving experience. This design choice fostered a more direct and immediate connection between driver input and vehicle response. Attention to detail extended to the steering wheel’s stitching – flat, precise stitching was used to provide a consistently smooth and tactile feel in the driver’s hands.

The seats in the 2014 C7 Stingray Corvette were another area of significant refinement. Two distinct seating options were offered to cater to different driving preferences:

- GT Seat: Designed for all-around comfort, ideal for daily driving and longer journeys.

- Competition Sport Seat: Featuring more aggressive side bolstering, providing enhanced support during spirited driving and track sessions.

Both seat designs shared a common foundation – a magnesium frame structure. This lightweight yet strong material offered greater rigidity and reduced weight compared to traditional steel frames. The increased rigidity contributed to the enhanced feeling of support, particularly during high-performance maneuvers.

Designers went beyond the drawing board, immersing themselves in the driving experience at GM’s Proving Ground in Milford, Michigan. These “field trips” to high-performance driving environments directly influenced the implementation of several interior features. A steel-reinforced grab bar on the center console provided the passenger with a secure hold during dynamic driving, while soft-touch materials on the console’s edge offered driver bracing comfort during high-load cornering.

The configurable display screens and available head-up display were also influenced by high-performance driving needs. The displays dynamically adapted based on the selected driving mode, with the Track display drawing inspiration from the C6.R race car, complete with a lap timer.

Beyond performance-oriented features, the interior of the 2014 C7 Stingray Corvette showcased an unprecedented level of attention to detail and build quality. A sweeping arch motif gracefully flowed over the driver cockpit trim, and a seamless transition was achieved between the instrument panel and the door panels.

Every surface within the cabin was fully wrapped in premium, soft-touch materials. Depending on the trim level chosen, available materials included luxurious Napa leather, sophisticated aluminum, sporty carbon fiber, and plush micro-suede.

The cabin’s ambiance was further elevated by a blend of hand craftsmanship and machined precision. The leather-wrapped instrument panel, for example, featured hand-selected and hand-stretched materials for optimal grain matching. Robotic stitching ensured perfect seams, showcasing a commitment to flawless execution. Even the passenger climate control received special attention, with a discreet micro-LED screen positioned below the vent on the dash, subtly separated from the driver’s performance-focused instrument panel.

Driver-Oriented Technologies: Tailoring Performance to Every Drive

The 2014 C7 Stingray Corvette placed the driver at the center of the experience, integrating a suite of driver-oriented technologies designed to optimize performance and personalize the driving dynamics. The centerpiece of this technological integration was the cockpit-mounted Driver Mode Selector.

This intuitive system allowed drivers to effortlessly adjust the car’s behavior to match their driving preferences and prevailing road conditions. Accessible via a rotary knob conveniently located near the shifter, the Driver Mode Selector offered five distinct settings:

- Weather: Primed for inclement conditions like rain and snow, enhancing confidence and stability.

- Eco: Optimized for maximum fuel efficiency during everyday driving.

- Tour: The default mode, calibrated for comfortable and relaxed daily driving.

- Sport: Sharpened responses for spirited road driving, emphasizing agility and engagement.

- Track: Unleashing the car’s full potential for track use, maximizing performance parameters.

Selecting each mode triggered adjustments across twelve key performance parameters, seamlessly transforming the driving character of the 2014 C7 Stingray Corvette. These parameters included:

- Gauge Cluster Configuration: The instrument cluster display dynamically changed with each mode. Tour, Eco, and Weather modes presented trip data, audio information, and navigation. Sport mode displayed classic, easy-to-read sports car gauges, while Track mode adopted a gauge layout inspired by the Corvette Racing C6.R race car, complete with a lap timer.

- ETC (Electronic Throttle Control): The throttle input curve was adjusted to match the selected mode, enhancing responsiveness in Sport and Track modes and smoothing inputs in Tour and Weather.

- Paddle-Shift Automatic Transmission (if equipped): Shift comfort and shift points were optimized for each mode, ranging from smooth and relaxed in Tour to quick and aggressive in Sport and Track.

- Active Fuel Management (AFM): In normal modes, the LT1 engine seamlessly switched between V-8 power during acceleration and fuel-saving V-4 mode when cruising. Eco mode prioritized V-4 operation for enhanced fuel economy, engaging V-8 only when aggressive acceleration was demanded.

- Exhaust (Active Exhaust System): The timing of electronically controlled exhaust valves was modulated to enhance the audible feedback from the V-8 engine, providing a more subdued note in Tour and Eco modes and a more aggressive growl in Sport and Track.

- Electronic Limited-Slip Differential (eLSD, Z51): The engagement rate of the eLSD was adjusted to balance steering response and stability. Sport and Track modes offered more aggressive performance, maximizing cornering prowess.

- Steering: Power steering assist was tailored to each mode, providing appropriate steering feel for the driving condition, with firmer feedback in Sport and Track.

- Magnetic Ride Control (if equipped): Shock damping was dynamically adjusted based on road conditions and driving mode, ranging from optimized comfort in Tour to maximum body control in Track.

- Launch Control: Available in Track mode for both manual and automatic transmissions, Launch Control optimized off-the-line acceleration for maximum performance.

- Active Handling (StabiliTrak Stability Control): Sport and Track modes offered a “Competitive” setting more permissive for track driving, while also allowing for complete system deactivation for experienced drivers seeking maximum control.

- Traction Control: Weather mode specifically tailored traction control and engine torque delivery for enhanced stability and grip in slippery conditions.

- Performance Traction Management (PTM): Exclusive to Track mode, PTM offered five selectable settings of torque reduction and brake intervention, allowing drivers to progressively dial in the desired level of electronic assistance for track driving.

Complementing the Driver Mode Selector were three configurable displays: dual eight-inch screens and an available color head-up display. These displays provided personalized information and visually communicated the different performance parameters associated with each drive mode.

The two eight-inch screens were engineered for exceptional visibility, even in direct sunlight. The instrument cluster screen boasted 650 cd/m2 of brightness, while the center stack screen reached an impressive 1,000 cd/m2, making them among the brightest screens in the automotive industry. The center stack screen incorporated touch-screen control with intuitive gesture recognition and could be lowered to reveal a hidden storage compartment, complete with a USB input for device charging and data uploads.

The 2014 C7 Stingray Corvette also featured an advanced infotainment system, incorporating Chevrolet MyLink and high-definition radio. Enhanced OnStar with 3D navigation maps provided seamless connectivity and guidance. Additional connectivity features included a USB port in the center console, a stand-alone audio input jack, and an SD card slot. An available premium 10-speaker audio system elevated the auditory experience, featuring a bass box, dual subwoofers, and speakers utilizing rare-earth magnets for enhanced sound quality with reduced weight and size.

Every Line Counts: Functionally Elegant Exterior Design

The exterior design of the 2014 C7 Stingray Corvette was a masterclass in functional elegance. Every line, vent, inlet, and surface was meticulously sculpted and optimized, not only for aesthetic appeal but also to enhance the car’s overall performance. Aerodynamic principles derived from Corvette Racing were seamlessly integrated into the design, resulting in a form that was as purposeful as it was beautiful.

While breaking new ground, the design thoughtfully retained signature Corvette cues. The distinctive long dash-to-axle ratio and the fighter jet-inspired greenhouse silhouette were recognizable hallmarks. The dual-element taillamps, a Corvette tradition, were reinterpreted with a modern edge. Building upon this foundation, designers drew inspiration from two seemingly disparate realms: aerospace engineering and natural forms.

Lighting played a pivotal role in defining the 2014 C7 Stingray Corvette’s visual identity and reinforcing its high-tech character. At the front, indirect white LED lamps created a distinctive daytime running light signature, housed within black-chrome lamp housings alongside standard HID projector headlamps. Edge-lit amber LED lighting was employed for the turn signals, adding a touch of sophistication.

The all-new, dual-element taillamps represented a significant departure from Corvette tradition and emerged as one of the car’s most dramatic design elements. Three-dimensional, sculpted lenses housed innovative indirect LED lighting. Hidden LED lamps projected their light upwards into a reverse reflector, creating a uniform and captivating glow. LEDs were also utilized for the white backup lamps. Functionally, the taillamps integrated aircraft-style air outlets, channeling airflow for the available differential and transmission coolers.

Aerodynamics were paramount in the design process. Advanced computer-aided modeling programs were employed to meticulously analyze and optimize airflow over, under, and through the Corvette’s body. Engineers and designers also leveraged data gleaned from the highly successful Corvette Racing program, a dominant force in the American Le Mans Series, to fine-tune the balance of front and rear grip, ensuring high-speed stability.

Extensive wind tunnel testing and hand-sculpting refined the surfaces for both aesthetics and performance. Functional exterior elements included:

- New Grille/Radiator Arrangement and Hood Vents: All models featured a redesigned grille and radiator configuration, along with functional hood vents. These vents effectively channeled air out of the hood, reducing front-end lift and enhancing steering response at high speeds.

- Front Fender Side Coves: These strategically placed coves further aided in venting underhood air pressure, contributing to a reduction in aerodynamic drag.

- Functional Side Vents (Automatic Transmission or Z51): Models equipped with the automatic transmission or the Z51 Performance Package incorporated functional vents on both driver and passenger sides. The driver’s side vent directed air over a heat exchanger for the transmission fluid, while the passenger side vent served a similar purpose for the electronic limited-slip differential.

- Integrated Cooling Airflow: Airflow channeled through the differential and transmission heat exchangers exited through the aircraft-inspired taillamp vents and lower-rear fascia air outlets, demonstrating a holistic approach to thermal management and aerodynamic efficiency.

- Z51 Performance Package Aero Enhancements: The Z51 Performance Package included brake-cooling ducts, a unique rear spoiler, and additional air deflectors, further augmenting track capability and high-speed stability.

Engineered to Race, Built for the Road: Advanced Engineering and Powertrain

The 2014 C7 Stingray Corvette’s performance prowess was rooted in its advanced engineering and meticulously developed powertrain. It was engineered with a racing spirit, yet refined for exceptional road manners. Lightweight materials, advanced manufacturing techniques, and technology transfer from the Corvette Racing program were all instrumental in achieving an ideal 50/50 weight balance and a world-class power-to-weight ratio.

The foundation of this performance was an all-new aluminum frame structure. Remarkably, it was 57 percent stiffer and 99 pounds (45 kg) lighter than the previous steel frame. This increased torsional rigidity not only enhanced handling precision but also reduced unwanted noise and vibrations, contributing to a more refined driving experience.

Compared to its predecessor, which utilized continuous hydroformed main frame rails with a constant 2mm wall thickness, the 2014 C7 Corvette’s frame employed a more sophisticated approach. Main rails were constructed from five customized aluminum segments, including aluminum extrusions at each end, a central main rail section, and hollow-cast nodes at suspension interface points. Each segment was meticulously tuned, with varying thicknesses ranging from 2mm to 11mm, optimizing gauge, shape, and strength characteristics for each frame section while minimizing weight.

Frame assembly took place in a brand-new welding shop at the Bowling Green Assembly Plant, utilizing a unique laser welding process. A computer-controlled beam of high energy joined components with exceptional precision, achieving tolerances of approximately 0.001-inch.

Supporting the frame’s enhanced strength and reduced weight were complementary chassis elements. Hollow-cast aluminum front and rear cradles, approximately 25 percent lighter and 20 percent stiffer than the solid cradles used in the previous generation, further contributed to the overall structural integrity and weight optimization.

Innovative material usage extended to the body panels. A standard carbon fiber hood and roof panel, along with underbody panels crafted from carbon-nano composite technology (an advanced blend of traditional composite material and carbon fiber), reduced weight without compromising strength or stiffness. Lighter-density Sheet Molded Compound was used for fenders, doors, rear quarter panels, and the rear hatch panel. Collectively, these material choices resulted in a body structure approximately 37 pounds (17 kg) lighter than its predecessor.

These lightweight elements directly contributed to the 2014 C7 Stingray Corvette’s ideal 50/50 weight balance. Coupled with its estimated 450 horsepower (335 kW), the new Corvette boasted a superior power-to-weight ratio compared to competitors like the Porsche 911 Carrera and Audi R8.

Powering this marvel was the all-new LT1 6.2L Small Block V-8 engine. Producing an estimated 450 lb.-ft. of torque (610 Nm), it delivered impressive low-end torque, matching the legendary 7.0L LS7 engine from the 2013 Corvette Z06 in the 1,000 to 4,000 rpm range.

The engine’s performance was a result of combining advanced technologies. Direct injection, Active Fuel Management, and continuously variable valve timing worked in concert with an advanced combustion system. Over 10 million hours of computational analysis went into the Small Block’s design, with over 6 million hours dedicated to optimizing the combustion system alone.

The LT1 engine was paired with a choice of active exhaust systems, both less restrictive than previous generations due to an increased diameter from 2.5 inches to 2.75 inches. The standard system offered a 13-percent improvement in airflow, featuring butterfly valves for enhanced refinement at cruising speeds when the engine operated in fuel-saving V-4 mode. An available dual-mode active exhaust system further boosted airflow by 27 percent, incorporating additional valves that opened to create a lower-restriction path through the mufflers, unleashing greater engine performance and a more powerful exhaust note.

Transmission choices included a six-speed paddle-shift automatic and an industry-exclusive TREMEC TR6070 seven-speed manual with Active Rev Matching. The Corvette retained its distinctive rear transaxle layout, optimizing weight balance. The seven-speed manual incorporated rev-matching technology for both upshifts and downshifts, selectable via steering wheel paddles. It featured a new dual-mass flywheel and dual-disc clutch for improved shift quality and feel. The Z51 Performance Package transmission included specific close-ratio gearing for more aggressive driving. The available six-speed Hydra-Matic 6L80 paddle-shift automatic was optimized for Active Fuel Management and featured a lower-inertia torque converter for enhanced shift quality and speed, with shift feel and points adjustable through the Driver Mode Selector.

More Direct, More Connected Driving Feel: Chassis, Suspension, and Brakes

The chassis and suspension of the 2014 C7 Stingray Corvette were meticulously engineered to capitalize on the lighter, stiffer structure. The reduced structural flex enabled engineers to fine-tune the suspension and steering for a more agile and responsive driving experience, creating a more direct and connected feel for the driver.

While maintaining the racing-proven short/long-arm suspension design, front and rear, all components were newly developed. Suspension enhancements included hollow lower control arms, saving approximately nine pounds (4 kg) per vehicle, and new aluminum rear toe links, reducing weight by 2.4 pounds (1.1 kg) compared to previous steel links.

The 2014 C7 Stingray Corvette rode on new 18 x 8.5-inch front and 19 x 10-inch rear wheels. Z51 Performance Package models featured larger 19 x 8.5-inch front and 20 x 10-inch rear forged aluminum wheels. New Michelin Pilot Super Sport run-flat tires, specifically developed for the seventh-generation Corvette, delivered comparable grip levels to the wider tires of previous models.

As a result, the track-oriented 2014 C7 Stingray Corvette with the Z51 Performance Package achieved 1g in cornering acceleration, matching the 2013 Corvette Grand Sport. This feat was accomplished with narrower and lighter wheels and tires, reducing rolling resistance, steering effort, and road noise, while enhancing agility, steering response, and touring comfort.

Dimensionally, the new Corvette’s wheelbase was approximately an inch longer than the previous generation, with front and rear tracks widened by almost an inch. These changes contributed to a more stable feel, especially at high speeds, while the turning radius was reduced by approximately two feet, improving maneuverability in tight spaces.

Standard 35mm-piston Bilstein monotube shocks connected to dual-path aluminum shock mounts, separating shock rod and body load paths. The Z51 Performance Package upgraded to 45mm-piston Bilstein dampers for more aggressive body control and track capability. Z51 offered the option of third-generation Magnetic Ride Control, featuring a new twin-wire/dual-coil damper system reacting 40 percent faster, improving both ride comfort and body control.

The new electric power steering system offered variable ratios and variable effort, tailoring responsiveness and feel for diverse driving situations. It delivered more precise control and feedback, along with greater variability of effort for high-performance driving and enhanced on-center sensitivity and linearity. Steering feel was further refined by increasing steering column stiffness by 150 percent, intermediate shaft torsional stiffness by 600 percent, and mounting the steering gear to the front cradle structure. The resulting steering system was five times stiffer than the previous generation.

A smart electronic limited-slip differential (eLSD), standard with the Z51 Performance Package, continuously optimized torque split between rear wheels. A hydraulically actuated clutch varied clutch engagement infinitely, transitioning from open to fully engaged in tenths of a second. An algorithm factoring in vehicle speed, steering input, and throttle position controlled torque distribution, enhancing steering feel, handling balance, and traction.

The eLSD was seamlessly integrated with StabiliTrak and Performance Traction Management systems, with calibrations varying across three modes based on the Driver Mode Selector setting:

- Mode 1: Default setting for normal driving, prioritizing vehicle stability.

- Mode 2: Activated when electronic stability control was disabled in Sport or Track Driver Modes, enabling nimbler turn-in and enhanced traction during corner exits.

- Mode 3: Automatically selected with Performance Traction Management, functioning similarly to Mode 2 but fine-tuned for optimal interaction with PTM.

Standard Brembo brakes, featuring racing-derived four-piston fixed calipers, delivered exceptional stopping power for both street and track use. System highlights included:

- Standard Brakes: 12.6-inch (320 mm) front rotors and 13.3-inch (338 mm) rear rotors, offering 35 percent more swept area than previous-generation brakes, improving stopping distance by 9 percent.

- Z51 Performance Package Brakes: Dual-cast, slotted 13.6-inch (345 mm) front rotors and 13.3-inch (338 mm) slotted rear rotors, with 6 percent more swept area than the previous-generation Grand Sport brakes, and front and rear cooling for enhanced track capability, improving stopping distance by 5 percent.

- Fixed Calipers: All brake packages utilized fixed front and rear calipers, enhancing pad wear, reducing drag, and improving modulation.

2014 Chevrolet Corvette Stingray Preliminary Specifications

| Overview | |

|---|---|

| Model: | 2014 Chevrolet Corvette Stingray |

| Body styles / driveline: | 2-door hatchback coupe with removable roof panel; rear-wheel drive |

| Construction: | composite and carbon-fiber body panels, hydroformed aluminum frame with aluminum and magnesium structural and chassis components |

| Manufacturing location: | Bowling Green, Ky. |

| Engine | LT1 6.2L V-8 |

|---|---|

| Displacement (cu in / cc): | 376 / 6162 |

| Bore & stroke (in / mm): | 4.06 x 3.62 / 103.25 x 92 |

| Block material: | cast aluminum |

| Cylinder head material: | cast aluminum |

| Valvetrain: | overhead valve, two valves per cylinder |

| Fuel delivery: | direct injection |

| Compression ratio: | 11.5:1 |

| Horsepower / kW: | 450 / 335 (est.) |

| Torque (lb-ft / Nm): | 450 / 610 (est.) |

| Transmissions | seven-speed manual with Active Rev Match | six-speed paddle-shift automatic |

|---|---|---|

| Type: |

| Chassis / Suspension | |

|---|---|

| Front: | short/long arm (SLA) double wishbone, cast aluminum upper and lower control arms, transverse-mounted composite spring, monotube shock absorber |

| Rear: | short/long arm (SLA) double wishbone, cast aluminum upper and lower control arms, transverse-mounted composite spring, monotube shock absorber |

| Active handling: | Magnetic Selective Ride Control (avail. with Z51) |

| Traction control: | StabiliTrak, electronic stability control |

| Brakes | |

|---|---|

| Type: | front and rear power-assisted discs with four-piston fixed front and rear calipers (slotted rotors with Z51) |

| Rotor diameter (in / mm): | front: 12.6 / 320 (13.6 / 345 with Z51) rear: 13.3 / 338 |

| Wheels / Tires | |

|---|---|

| Wheel size: | front: 18-inch x 8.5-inch (Stingray) front: 19-inch x 8.5-inch (with Z51) rear: 19-inch x 10-inch (Stingray) rear: 20-inch x 10-inch (with Z51) |

| Tires: | Michelin Pilot Super Sport run-flat front: P245/40R18 (Stingray) front: P245/35R19(with Z51) rear: P285/35R19 (Stingray) rear: P285/30R20(with Z51) |

| Dimensions Exterior | |

|---|---|

| Wheelbase (in / mm): | 106.7 / 2710 |

| Overall length (in / mm): | 177 / 4495 |

| Overall width (in / mm): | 73.9 / 1877 |

| Overall height (in / mm): | 48.6 / 1235 |

| Weight distribution (% front / rear): | 50 / 50 |

All-New 2014 Corvette LT1 V-8: A Technological Powerhouse Under the Hood

The heart of the 2014 C7 Stingray Corvette was its revolutionary LT1 V-8 engine. This marked the debut of the Gen 5 family of Small Block engines, combining racing-proven heritage with state-of-the-art technology. The 6.2L LT1 was engineered to deliver an estimated 450 horsepower, enabling 0-60 mph acceleration in under four seconds, while simultaneously achieving best-in-class fuel economy for a Corvette.

Mary Barra, Senior Vice President, Global Product Development, emphasized the ambitious goals for the LT1’s development: “Our objective for the development of the all-new LT1 was to raise the bar for performance car engines. We feel that we have achieved that by delivering a true technological masterpiece that seamlessly integrates a suite of advanced technologies that can only be found on a handful of engines in the world.”

Barra further highlighted the engine’s core innovation: “What makes this engine truly special is the advanced combustion system that extracts the full potential of these technologies. The art and science behind that combustion system make the Corvette LT1 one of the most advanced V-8 engines in the world.”

The LT1 engine was projected to deliver:

- Unprecedented Power: The most powerful standard Corvette engine ever, with a preliminary output of 450 horsepower (335 kW) and 450 lb.-ft. of torque (610 Nm).

- Blistering Acceleration: The quickest standard Corvette ever, accelerating from 0-60 mph in an estimated four seconds.

- Exceptional Fuel Efficiency: The most fuel-efficient Corvette to date, exceeding the 2013 EPA-estimated 26 miles per gallon on the highway.

Tadge Juechter, Corvette Chief Engineer, summarized the LT1’s achievement: “The Holy Grail for developing a performance car is delivering greater performance and more power with greater fuel economy and that’s what we’ve achieved. By leveraging technology, we are able to get more out of every drop of gasoline and because of that we expect the new Corvette will be the most fuel-efficient 450 horsepower car on the market.”

Advanced Combustion System: Optimized Through Millions of Hours of Analysis

Sam Winegarden, Vice President, Global Powertrain Engineering, underscored the LT1’s significance in the Small Block legacy: “The Corvette LT1 represents the most significant redesign in the Small Block’s nearly 60-year history – building on its legacy to make one of the world’s best engines even better. More than just great horsepower, the LT1 has been optimized to produce a broader power band. Below 4,000 rpm, the torque of the Corvette LT1 is comparable to that of the legendary, 7.0L LS7 out of the current Corvette Z06. The LT1 is a sweetheart of a power plant and drivers will feel its tremendous torque and power at every notch on the tachometer.”

The increased power and efficiency of the LT1 were made possible by an unprecedented level of computational analysis. Computational fluid dynamics were employed to optimize the combustion system, direct injection fuel system, Active Fuel Management, and variable valve timing systems. Over 10 million hours of computational analysis were dedicated to the engine program, with 6 million hours specifically focused on the advanced combustion system.

Key Technologies of the LT1 Engine:

- Direct Injection: A first for the Corvette, direct injection significantly enhanced combustion efficiency by ensuring a more complete fuel burn. Precise control over mixture motion and fuel injection spray patterns was achieved. Direct injection also cooled the combustion chamber, enabling a higher compression ratio and reducing cold-start hydrocarbon emissions by approximately 25 percent.

- Active Fuel Management (AFM): Another Corvette first, AFM imperceptibly shut down half of the engine’s cylinders during light-load driving, improving fuel economy without compromising performance.

- Continuously Variable Valve Timing (VVT): Refined VVT, a GM-pioneered technology for overhead-valve engines, worked in conjunction with AFM and direct injection to further optimize performance, efficiency, and emissions.

These technologies synergistically supported the all-new advanced combustion system. This system incorporated a redesigned cylinder head and a sculpted piston design, integral to achieving the high compression and mixture motion parameters enabled by direct injection.

The LT1 cylinder head featured smaller combustion chambers, designed to complement the unique topography of the piston heads. The smaller chamber size and sculpted pistons yielded an 11.5:1 compression ratio. Large, straight, rectangular intake ports with a slight twist enhanced mixture motion. The intake and exhaust valve positions were reversed compared to previous designs, and the spark plug angle and depth were revised to protrude further into the chamber, positioning the electrode closer to the combustion center for optimal ignition.

The pistons featured unique sculpted topography, optimized through extensive analysis to precisely direct fuel spray for more complete combustion. The contours of the piston heads were machined for dimensional accuracy, crucial for precise control of mixture motion and compression ratio.

Race-Proven Legacy, State-of-the-Art Performance: The Small Block Heritage

The Small Block V-8 engine, a cornerstone of Chevrolet performance, debuted in the Corvette in 1955. The original 4.3L (265 cubic inches) engine produced 195 horsepower, utilizing a four-barrel carburetor. Just five years later, V-8 power propelled Corvette to its first victory at the 24 Hours of Le Mans.

In 2012, the Small Block-powered Corvette Racing C6.R dominated the production-based American Le Mans Series GT class, securing drivers’, team, and manufacturer championships against formidable competitors like Ferrari, BMW, and Porsche. Corvette Racing became the most successful team in ALMS history, with 77 class wins, eight drivers’ championships, and nine manufacturer and team championships since 2001.

Jordan Lee, Small Block Chief Engineer and Program Manager, emphasized the shared engineering principles between production and race engines: “The engine requirements for a production car and a race car are remarkably similar. In both cases, you want an engine that is powerful and efficient, compact and lightweight, and durable. That combination is what made the original Small Block so successful. Today, the introduction of state-of-the-art technologies and engineering makes one of the best performance car engines in the world even better.”

The LT1 exemplified these principles. It was 40 pounds lighter than a competitor’s twin-turbo 4.4L DOHC V-8 with similar output. This weight savings improved the Corvette’s power-to-weight ratio and contributed to its near-perfect 50/50 weight balance, enhancing steering response and handling. The LT1 was also four inches shorter in overall height than the competitive DOHC V-8, lowering the center of gravity, enabling a low hood line, and contributing to the Corvette’s iconic profile and exceptional driver visibility.

The 2014 C7 Stingray Corvette’s LT1 was the third engine in Corvette history to bear the LT1 name, with previous iterations introduced in 1970 (Gen 1) and 1992 (Gen 2). All LT1 engines, and all Small Block engines, shared a compact design philosophy, providing packaging flexibility in sleek vehicles like the Corvette.

Lee concluded, “The power and efficiency of the Small Block V-8 are hallmarks of Corvette performance. But, the compact size and great power-to-weight are just as important for the overall driving experience. The all-new LT1 will play a huge role in making the all-new Corvette a world-class sports car, in terms of technology, performance, and refinement.”

Key Engine Features and Highlights:

-

All-aluminum block and oil pan: A light, rigid foundation for a smooth engine, developed using math-based tools and racing program data. Deep-skirt design maximized strength and minimized vibration. Bulkheads accommodated six-bolt, cross-bolted main-bearing caps for crank flex limitation and structural stiffening. A structural aluminum oil pan further stiffened the powertrain. Nodular iron main bearing caps, stronger and better at absorbing vibrations than conventional powdered metal caps, enhanced smoothness and quietness. The Gen 5 block casting was all-new but based on the same architecture, refined to accommodate the direct injection high-pressure fuel pump, with new engine mount attachments, knock sensor locations, improved sealing, and oil-spray piston cooling.

-

Advanced oiling system, with available dry-sump system: Optimized for performance, driven by a new variable-displacement oil pump for efficient oil delivery based on engine conditions. Dual-pressure control enabled efficient low-rpm operation with AFM and higher pressure at high speeds for robust lubrication during aggressive driving. Standard oil-spray piston cooling provided extra lubrication at start-up and cooling at high speeds via jets at the cylinder bottom. An available dry-sump oiling system with pressure and scavenge stages ensured exceptional lubrication during aggressive maneuvers and high cornering loads. Dexos semi-synthetic 5W30 motor oil reduced friction, enhancing efficiency.

-

New, tri-lobe camshaft: Positioned similarly to the Gen 4 Small Block cam, but with a new rear cam bearing and an all-new “tri-lobe” design exclusively driving the direct injection high-pressure fuel pump. Cam specifications included 14mm/13.3mm intake/exhaust lift, 200/207-crank angle degrees intake/exhaust duration at 0.050-inch tappet lift, and a 116.5-degree cam angle lobe separation.

-

New, cam-driven fuel pump: The direct injection system featured a very-high-pressure fuel pump delivering up to 15Mpa (150 bar), fed by a conventional tank-mounted pump. The high-pressure pump was mounted in the valley between cylinder heads, driven by the camshaft at the engine rear, muffling pump noise.

-

PCV-integrated rocker covers: Domed rocker covers housed a patent-pending integrated positive crankcase ventilation (PCV) system, enhancing oil economy and life, reducing oil consumption and emissions. Rocker covers also held direct-mount ignition coils for the coil-near-plug ignition system. Domed sections contained baffles for enhanced oil/air separation from crankcase gases.

-

Intake manifold and throttle body assembly: The LT1 intake manifold featured a “runners in a box” design for high-efficiency airflow within the low hood line. Acoustic foam and a shell reduced radiated engine and fuel pump noise. An electronically controlled throttle with an 87mm bore and a durable “contactless” throttle position sensor provided enhanced control.

-

Four-into-one exhaust manifolds: Cast version of the “four-into-one” short-header exhaust manifold design from the Gen 4 LS7 engine, enabling consistent exhaust flow into the “wide mouth” collector at the converter.

-

Cooling system, humidity sensor and more: Revised cooling system with offset water pump and thermostat for efficiency. Air induction humidity sensor ensured optimal combustion efficiency. 58X ignition system with individual ignition coil modules and iridium-tip spark plugs. All-new “E92” engine controller.

General Motors’ investment in the Gen 5 Small Block created or retained over 1,600 jobs in North American plants, including Tonawanda, New York, which received upgrades for production.

The 2014 C7 Stingray Corvette was more than just a car; it was a statement. A statement of innovation, performance, and the enduring legacy of the Stingray. It marked not just a return, but a triumphant leap forward for the American sports car.