For anyone who owns a car, adding engine oil is a routine maintenance task. We know it goes in at the top and drains out from the bottom, but what happens in between? Having spent 35 years in auto repair, the journey of engine oil within the engine is clear to me. However, many car owners lack a comprehensive understanding of the path oil takes and the crucial role of Car Engine Oil Parts. A frequent question I encounter is:

“How often should I change my car’s oil, and what type should I use?”

To provide the best advice, I usually respond with a series of questions: What type of vehicle do you drive? What are your typical driving conditions? Where do you live, considering climate? And how old is your car? The answers to these questions are vital in determining the optimal engine oil for your specific needs. Choosing the right oil ensures maximum protection and lubrication for your engine as it circulates through the car engine oil parts.

The Journey of Engine Oil Through Car Engine Oil Parts

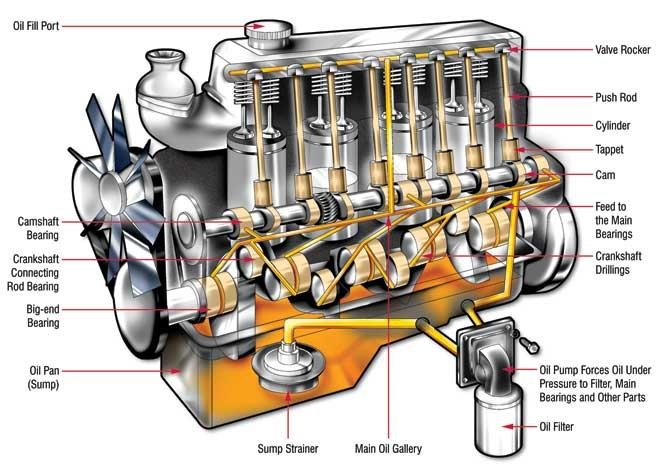

Let’s delve into where the oil travels, the sequence of its journey, and its precise functions within your engine. When you pour oil into the engine, it embarks on a multi-stage path, eventually collecting in the oil pan, also known as the sump, where the drain plug is located. While oil returns to the sump via several routes, it’s the pressurized path that performs the essential task of lubrication through various car engine oil parts.

Figure 1 illustrates the oil pickup system within the sump. A tube with a loose-weave metal screen sits at the bottom of the oil pan. This screen is connected to the oil pickup tube, which leads directly to the oil pump. Submerged approximately four inches deep in the oil, this assembly ensures the pump draws oil and the screen acts as a primary defense, preventing larger debris—typically anything larger than 1/32nd of an inch—from entering the oil pump and other critical car engine oil parts.

Many are unaware that most oil pumps are essentially specialized gear sets. These gears draw oil at low pressure and then compress it to high pressure. The pressurized oil then flows through a chamber containing a spring-loaded valve. This valve regulates the oil pressure, allowing it to proceed only when it reaches a specific pressure range, usually between 1 and 60 psi. Excess pressure is vented back to the sump because overly high oil pressure can damage engine bearings, which are vital car engine oil parts.

From the pump, the oil is directed to the exterior of the oil filter. Here, it’s forced through the filter media, exiting from the center and entering the engine’s oil galleries. The oil filter, a key car engine oil part, also incorporates a bypass valve. This crucial feature prevents pressure drops if the filter becomes clogged, ensuring continuous oil flow. The primary function of motor oil is to lubricate the engine’s rotating components under adequate pressure.

The pressurized oil is then forced into the minute clearances between bearings and crankshaft journals. Bearings, essential car engine oil parts, are simple metal sleeves that encircle the engine’s rotating components. The engine block houses main bearings for the crankshaft, while connecting rods have bearings on the crank throws.

This thin space, often just one-thousandth of an inch in modern engines, maintains a thin film of oil between the bearings and the moving crankshaft surfaces. At the correct operating temperature and pressure, this oil film is critical for protecting and extending the lifespan of these precisely machined car engine oil parts. Direct metal-to-metal contact between moving surfaces must be avoided.

It’s noteworthy that some oil is expelled from the sides of the bearings and returns to the sump. Excessive bearing clearance, for instance, 0.004 inches or more, can lead to a drop in oil pressure in the upper engine regions. Symptoms like a flickering oil pressure light or a slight tapping noise in the rocker arm area can indicate insufficient oil pressure reaching the upper engine, signaling potential issues with car engine oil parts or oil pressure.

On a slightly different note, I often contemplate the advantages of roller or needle bearings in automotive engines instead of the more common sleeve bearings. While sleeve bearings are cost-effective and sufficiently durable, roller or needle bearings, though more expensive, could offer significantly extended engine life. Larger engines frequently utilize needle/roller bearings, typically operating at lower RPMs than gasoline car engines. However, RPM is not the only limiting factor.

In my 40 years of experience with model airplanes, many high-revving engines (25,000+ RPM, compared to 2,500 RPM in a car engine) use roller bearings for reduced friction and higher RPM capabilities. An automotive engine equipped with roller/needle bearings could potentially deliver increased power and longevity, but the production costs would be considerably higher. The current sleeve bearing system, while simpler and more affordable, is a critical set of car engine oil parts that performs adequately for most vehicle lifespans.

While most oil is directed to lubricate the crankshaft area, a portion is routed to the camshaft and rocker arms, also crucial car engine oil parts. In vehicles with pushrods instead of overhead camshafts, oil is pressurized into the valve lifters. These lifters then pump oil through hollow pushrods to lubricate the rocker arm area. For cars with overhead camshafts, oil is delivered to the cam and distributed onto the contact points between the cam and valve stems.

After lubricating the camshaft and related car engine oil parts, the oil flows by gravity back through channels in the head and engine block, returning to the sump, ready for another cycle.

Many connecting rod designs incorporate a small orifice that sprays oil onto the cylinder walls. This lubrication is essential for the piston ring contact area within the cylinder. Special rings on the lower piston ring set then scrape off excess oil, returning it to the sump. Piston rings are vital car engine oil parts for oil control and engine efficiency.

Regarding oil consumption, it’s often necessary to add a quart of oil between regular 3,000-mile intervals. Newer vehicles often show minimal to no oil consumption during initial oil change intervals. However, oil consumption tends to increase gradually as the vehicle ages. What constitutes excessive oil consumption? Ideally, one quart every 5,000 miles is reasonable. One of my most reliable vehicles signaled its need for an oil change by requiring a quart every 4,000 miles. Instead of just adding a quart, I used this as a prompt to change the oil and filter entirely.

Personally, I view slight oil consumption as beneficial. In my extensive experience as an auto mechanic, engines that consume a small amount of oil, allowing it to bypass the rings, often exhibit reduced wear on the upper cylinder and rings. Historically, we even added top oil to gasoline for this very purpose.

External oil leaks, however, are problematic. They are messy, pose a potential fire risk, and are visually unappealing. Used car dealerships invest considerable effort in cleaning engines before putting vehicles on display. Our initial impression of an engine is heavily influenced by its cleanliness and smooth operation. Prospective buyers often inspect under the hood before even starting the engine. If a salesperson starts the car before opening the hood, it might be an attempt to mask a dirty engine and potential oil leaks with the positive first impression of a smoothly running engine.

If a dealer hasn’t cleaned the engine, it’s likely hiding an oil leak they prefer not to address. After a test drive, always check the parking spot for oil stains—this can be a point of negotiation. Many oil leaks are often repairable for under $100. Addressing leaks ensures all car engine oil parts are properly lubricated and functioning.

Understanding Oil Consumption in Car Engine Oil Parts System

A reader recently posed three insightful questions regarding their car’s increased oil consumption after an oil change. For the first 30,000 miles, their vehicle showed no oil consumption between changes. Suddenly, oil consumption increased to one quart every 1,000 miles. While this rate suggests a significant leak or oil burning issue, the reader’s questions are valid:

-

What is considered normal oil consumption? Why did the car initially burn no oil for 30,000 miles?

-

Why does oil consumption primarily occur during highway driving and not in stop-and-go conditions?

-

What could cause this sudden change in oil consumption pattern after 30,000 miles?

Oil consumption generally increases with vehicle age. Defining “normal” consumption is subjective, but I consider one quart per 5,000 miles to be reasonable. As mentioned, many newer cars may not consume any oil initially—this also varies.

The fact that consumption is more pronounced during highway driving suggests a potential internal oil leak, possibly around the valve stem seals, or an issue within the PCV system. Highway driving puts more sustained stress and higher temperatures on car engine oil parts, potentially exacerbating leaks or burning issues.

The abrupt change in oil consumption pattern strongly indicates a new issue—either a previously undetected leak or a sudden increase in oil burning. Regular checks of car engine oil parts and oil levels are crucial for early detection of such problems.

I own a car with over 175,000 miles that consumes oil at my preferred rate: one quart every 4,000 miles. My newer car, with only 70,000 miles, also consumes about one quart every 4,000 miles, a pattern it has exhibited since new.

Oil leaks can be challenging to locate in modern vehicles. Engine compartments are often tightly packed, limiting visibility from various angles. Numerous accessories bolted to the engine block further obscure visual inspection. However, in an upcoming issue of Machinery Lubrication, I will discuss some of the latest leak-detection methods. Techniques using phosphorescence, polymer acrylics, ultraviolet light, smoke, and even mirrors will be explored. These advanced methods can aid in pinpointing leaks in various car engine oil parts and systems.

About the Author