Have you ever stopped to consider just how many individual pieces come together to make your car function? It’s easy to take for granted the seamless operation of our vehicles, but beneath the sleek exterior lies a complex assembly of thousands of components working in harmony. The answer to the question “how many parts does the average car have?” might surprise you, and it depends on how you’re counting.

When you break it down to the smallest elements, including every nut, bolt, and tiny clip, the average car contains roughly 30,000 parts. This staggering number highlights the incredible intricacy of modern automotive engineering. However, if you consider larger assemblies as single units – like counting the entire engine as one part instead of its individual pistons, valves, and gaskets – the number drops significantly to around 1,800 separate parts. Even this lower figure underscores the impressive complexity involved in manufacturing and assembling a car.

The Sheer Scale of Automotive Parts

That figure of 30,000 parts truly illustrates the vastness of the automotive industry and the intricate supply chains involved. Each of these parts, from the smallest fastener to sophisticated electronic sensors, plays a crucial role in the vehicle’s overall performance, safety, and comfort. Think about the myriad systems within a car: the engine, transmission, braking system, electrical system, cooling system, and interior, each composed of hundreds or thousands of individual components.

This massive number of parts also reflects the precision and coordination required in automotive manufacturing. Each part must be manufactured to exacting specifications and then assembled correctly, often with robotic automation and skilled human labor working in concert within massive assembly plants.

Counting Major Components: A More Practical Perspective

While 30,000 is an impressive figure, the 1,800 parts estimate offers a more practical perspective when considering the major systems and assemblies of a car. This count focuses on the primary components that make up the vehicle’s core functions. For example, the engine itself, though counted as one “part” in this context, is an incredibly complex assembly containing thousands of internal pieces. Similarly, the transmission, the braking system, and the exhaust system are each considered single units in this count, despite being composed of numerous individual parts.

To put these parts together, a car requires a significant amount of welding. In fact, the average car needs up to 4,800 welds to join its various components and body panels. The assembly process is also time-consuming, with a single car taking around 19 hours of assembly time in a modern factory. These factories are marvels of efficiency, with modern production lines churning out around 1,450 cars per day. This is a stark contrast to the early days of automotive production, where limited runs of classic cars might only total a few hundred units.

Key Car Systems and Their Components

Let’s look at some key car systems and the types of parts they include to appreciate this complexity:

-

Engine: The heart of the car, containing parts like the cylinder head, pistons, camshaft, crankshaft, valves, spark plugs, fuel injectors, oil filter, water pump, and many more.

-

Drivetrain: This system transfers power to the wheels and includes the transmission, axles, differential, driveshaft (in rear-wheel drive vehicles), and constant velocity (CV) joints.

-

Braking System: Essential for safety, it consists of brake pads, rotors, calipers, brake lines, master cylinder, and anti-lock braking system (ABS) components.

-

Suspension System: Ensures a smooth ride with parts like shock absorbers, struts, springs, control arms, and bushings.

-

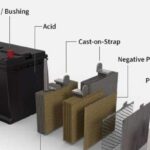

Electrical System: Powers all electronic components, including the battery, alternator, starter motor, wiring harnesses, sensors, and electronic control units (ECUs).

-

Cooling System: Prevents overheating with components such as the radiator, water pump, thermostat, hoses, and coolant.

Engine Components in Detail

Delving deeper into just one system, the engine, reveals further layers of complexity. An exploded view of an engine highlights numerous key components, including the cylinder head cover, cylinder head, exhaust manifold, camshaft pulley, oil filter, water pump, oil pan, engine block, and timing belt.

Engine blocks themselves can be made from different materials, each with its own advantages and disadvantages. Older and classic cars often utilized cast iron for engine blocks due to its affordability and thermal stability, though it is heavier. Modern vehicles frequently employ aluminum or aluminum alloys, which are lighter and improve fuel efficiency, although they can be more expensive.

Where to Find Replacement Parts

Whether you are maintaining a modern vehicle or restoring a classic car, understanding the vast number of parts underscores the importance of readily available replacement components. For modern cars, dealerships, auto parts stores, and online retailers are common sources. For classic car enthusiasts, finding parts can be more specialized, leading them to resources like classic car parts suppliers, salvage yards, swap meets, and classic car clubs.

Conclusion

From the tens of thousands of tiny pieces to the thousands of welds and hours of assembly, the average car is a testament to human ingenuity and engineering prowess. Whether you consider the granular count of 30,000 parts or the more practical estimate of 1,800 major components, it’s clear that automobiles are incredibly complex machines. The next time you get behind the wheel, take a moment to appreciate the sheer number of parts working together to provide you with transportation, comfort, and convenience.