Turbocharging your car is a popular and effective method to significantly enhance engine power and overall vehicle performance. By forcing more air into the engine cylinders, turbochargers allow for increased combustion, resulting in a substantial boost in horsepower and torque. While the core concept is straightforward, successfully turbocharging a car involves a system of interconnected components working in harmony. This guide will break down all the essential parts you’ll need to turbocharge your car, ensuring you understand each component’s role and importance.

The Turbocharger: The Heart of the System

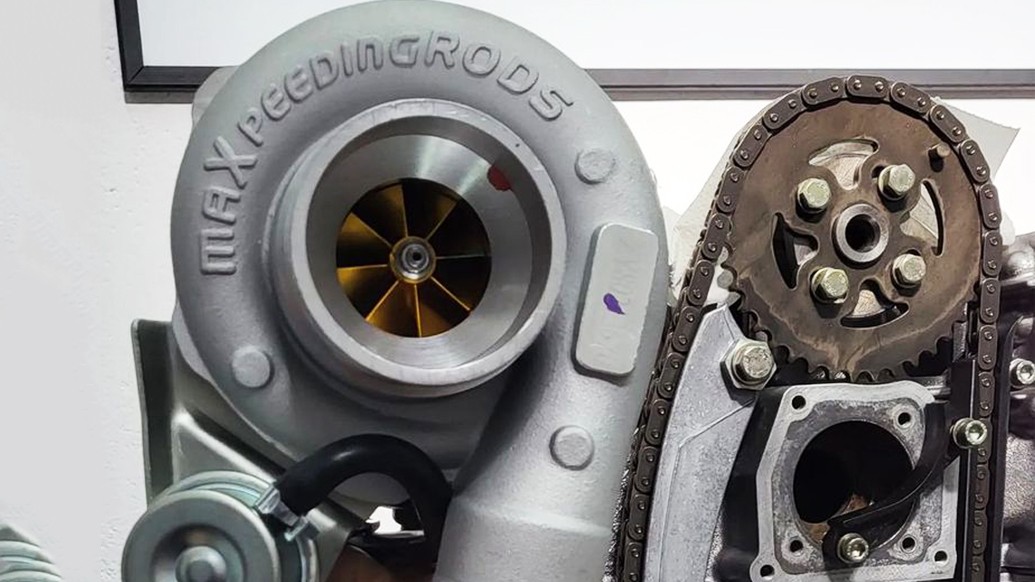

At the very core of any turbocharging system is the turbocharger itself. This ingenious device is responsible for compressing ambient air and delivering it to the engine’s intake manifold at increased pressure. A turbocharger is comprised of two main sections:

- Turbine: This component is a turbine wheel that is spun by the engine’s exhaust gases. As exhaust gas exits the engine, it flows through the turbine housing, causing the turbine wheel to rotate at high speeds.

- Compressor: Directly connected to the turbine wheel via a shaft, the compressor wheel is located in the compressor housing. As the turbine spins, it forces the compressor to spin as well. This rotation draws in fresh air and compresses it, significantly increasing its density.

The size and specifications of the turbocharger are crucial and must be carefully matched to your engine’s displacement and desired power goals. Choosing the right turbocharger is the first and most critical step in the turbocharging process.

Exhaust Manifold: Directing Exhaust Energy

The exhaust manifold plays a vital role in a turbocharged system. In a naturally aspirated engine, the exhaust manifold simply directs exhaust gases away from the engine. However, in a turbocharged setup, the exhaust manifold has the crucial task of channeling the exhaust gases to the turbine of the turbocharger.

For optimal turbo performance and efficiency, it’s often necessary to upgrade the stock exhaust manifold to a turbo manifold. Turbo manifolds are designed with specific runner lengths and configurations to efficiently direct exhaust flow to the turbocharger, maximizing the energy available to spin the turbine. The design of the exhaust manifold can significantly impact turbo spool-up time and overall system responsiveness.

Intercooler: Cooling Down Compressed Air for Density

As air is compressed by the turbocharger, its temperature rises significantly. Hot air is less dense than cold air, meaning it contains less oxygen per unit volume. To maximize the benefits of turbocharging, it’s essential to cool down the compressed air before it enters the engine. This is where the intercooler comes into play.

An intercooler is essentially a heat exchanger, similar to a radiator, that cools the compressed air. By reducing the intake air temperature, the intercooler increases the density of the air entering the engine. Denser air means more oxygen for combustion, leading to more power and reduced risk of detonation. Intercoolers can be air-to-air or air-to-water, with air-to-air being the more common type in aftermarket turbo kits.

Wastegate: Regulating Boost Pressure for Engine Safety

Controlling boost pressure is critical for engine longevity and performance. Excessive boost can lead to engine damage, while insufficient boost limits power gains. The wastegate is the component responsible for regulating the maximum boost pressure in a turbo system.

A wastegate is a valve that allows exhaust gases to bypass the turbine wheel once a pre-set boost pressure is reached. By diverting exhaust flow away from the turbine, the wastegate prevents the turbocharger from spinning faster and creating excessive boost. Wastegates can be internal (integrated into the turbocharger housing) or external (separate unit mounted on the exhaust manifold). A reliable wastegate is crucial for preventing overboost and ensuring engine safety.

Blow-Off Valve (BOV): Protecting the Turbo from Pressure Surges

When the throttle is suddenly closed, for example, when shifting gears or decelerating, the compressed air built up by the turbocharger suddenly has nowhere to go. This can create a pressure surge that can damage the turbocharger. The blow-off valve (BOV), sometimes also referred to as a diverter valve, prevents this damaging pressure surge.

A BOV is a pressure relief valve that vents excess compressed air to the atmosphere or back into the intake system when the throttle is closed. This release of pressure prevents compressor surge, which can cause turbocharger damage and reduce its lifespan. The characteristic “whoosh” sound often associated with turbocharged cars is the sound of the blow-off valve releasing pressure.

Essential Supporting Components: Ensuring System Integration

Beyond the major components, a successful turbo installation requires a range of supporting parts to ensure proper function and reliability. These include:

- Turbo Piping/Intercooler Piping: These pipes connect the turbocharger to the intercooler and the intercooler to the intake manifold. They must be robust enough to handle pressurized air and high temperatures.

- Silicone Couplers and Clamps: Used to connect sections of piping and components, silicone couplers provide flexibility and sealing, while clamps ensure secure connections under pressure.

- Oil Lines and Fittings: Turbochargers require lubrication to function properly. Oil feed and drain lines are essential for supplying oil to the turbo bearings and returning it to the engine oil system.

- Coolant Lines and Fittings (for Water-Cooled Turbos): Some turbochargers are water-cooled to help manage heat. Coolant lines and fittings are necessary to integrate the turbo’s cooling system with the engine’s coolant system.

- Boost Controller (Optional but Recommended): A boost controller allows for fine-tuning and adjustment of the boost pressure, giving you more control over your engine’s power output.

- Engine Management System (ECU) Tuning: Arguably one of the most crucial “parts” is proper engine tuning. Turbocharging drastically changes the engine’s air and fuel requirements. ECU tuning is essential to optimize the air-fuel ratio, ignition timing, and other parameters to ensure safe and efficient operation with the turbocharger. This often involves reprogramming the car’s computer or installing a standalone engine management system.

Conclusion: A System Approach to Turbocharging

Turbocharging your car is a complex modification that requires careful planning and the right components. As you can see, it’s not just about bolting on a turbocharger. A successful and reliable turbo system relies on the harmonious interaction of all the parts discussed – from the turbocharger itself to the intercooler, wastegate, blow-off valve, and the essential supporting components, including proper ECU tuning.

When embarking on a turbocharging project, thorough research, careful component selection, and professional installation or tuning (if you are not experienced) are highly recommended. By understanding all the parts needed to turbocharge your car and their respective roles, you can make informed decisions and enjoy the exhilarating performance boost that turbocharging offers while maintaining the longevity and reliability of your engine.