Beyond the engine’s roar and the sleek exterior, lies a network of critical components beneath your vehicle – the undercarriage. Often overlooked, the car undercarriage is a complex assembly of parts that are fundamental to your car’s handling, safety, and overall performance. From bushings and bearings to the very wheels themselves, each component plays a vital role. Ignoring undercarriage maintenance can lead to discomfort, diminished performance, and in severe cases, dangerous driving conditions.

So, what exactly are the Undercarriage Parts Of A Car, and why is their maintenance so crucial? This guide will delve into the essential components, their functions, and the tell-tale signs that indicate they might need attention.

Understanding the Key Components of Your Car’s Undercarriage

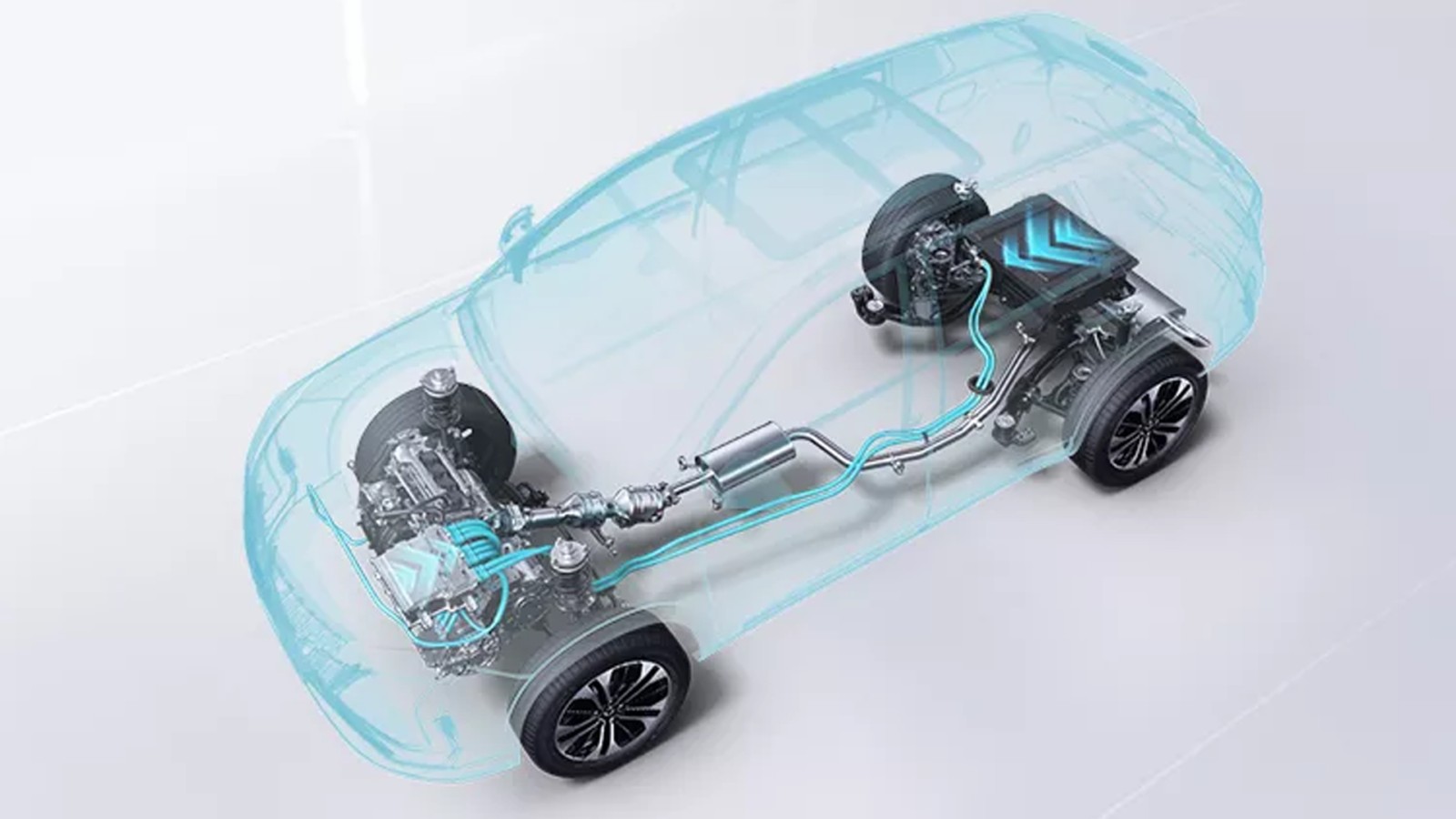

The undercarriage is not a single entity but a collection of interconnected parts, each with a specific function. Servicing the undercarriage requires understanding these individual components and how they contribute to the vehicle’s overall operation. Let’s explore some of the most crucial undercarriage parts:

1. Bushing Arm (Control Arm Bushings)

Bushing arms, more accurately known as control arm bushings, serve as pivotal connections within your vehicle’s suspension system. They act as the fulcrum for the wheels and provide crucial attachment points for various undercarriage components. Furthermore, these bushings are designed to dampen vibrations and reduce road noise transmitted into the cabin, enhancing ride comfort.

A failing bushing arm can significantly impact vehicle stability. If you notice your car drifting to the left or right, especially at higher speeds, it could indicate worn or damaged control arm bushings. Prompt repair is necessary to restore handling and ensure safe driving.

2. Wheel Bearings

Wheel bearings are essential components that enable the wheels to rotate smoothly and freely. Located within the wheel hub, these bearings reduce friction, allowing for efficient and stable wheel rotation, which is critical for vehicle movement and handling.

Diagnosing a wheel bearing issue often involves a simple test. By jacking up the car and manually spinning each tire, you can listen for unusual noises like grinding, rumbling, or clicking. Any such sounds suggest that the wheel bearing is worn and requires immediate replacement to prevent wheel instability and potential failure.

3. Suspension System

The suspension system is designed to maximize tire contact with the road surface, especially when driving over uneven terrain. Typically constructed from robust steel, the suspension system is engineered for durability. However, over time and with prolonged use, suspension components can wear down, leading to a decrease in performance.

Worn suspension can manifest as a bouncy or unsteady ride, particularly when encountering bumps or potholes. Driving at high speeds with a compromised suspension can be particularly dangerous, leading to reduced control and increased risk of accidents. Regular suspension checks are vital for maintaining ride comfort and vehicle safety.

4. Ball Joints

Ball joints are pivotal links connecting the steering knuckles to the control arms. These components allow for smooth and controlled steering, enabling the wheels to turn effectively. They play a crucial role in maintaining stable and responsive handling during turns and maneuvers.

Signs of ball joint wear include scraping or clunking noises when the car is jacked up or when the wheels are moved vertically. Ignoring worn ball joints can lead to steering instability and, in severe cases, separation, resulting in loss of steering control.

5. Coil Springs (Per)

Coil springs, often referred to as “pers,” are a vital part of the suspension system, responsible for supporting the vehicle’s weight and absorbing shocks from road irregularities. While generally robust, coil springs can experience issues, although less frequently than other suspension parts.

Damage to coil springs can be challenging to detect visually unless there’s a clear fracture of the spring coil. However, corroded or damaged spring seats or bushings can indicate underlying coil spring issues. Replacing worn coil springs is crucial for maintaining proper ride height and suspension performance.

6. Tie Rods

Tie rods are direct links between the steering rack and the steering knuckles, transmitting steering input from the steering wheel to the wheels. These components are crucial for precise steering and directional control.

A problem with tie rods can lead to noticeable issues with steering alignment, often causing the car to pull to one side. If you experience your vehicle veering to the left or right without intentional steering input, it is essential to inspect and potentially service the tie rods immediately to restore proper steering and handling.

7. Shock Absorbers (Shockbreakers)

Shock absorbers, sometimes called “shockbreakers,” are key components in the suspension system designed to dampen oscillations and control spring and suspension movement. They ensure a smoother ride by minimizing the impact of bumps and uneven road surfaces.

Worn shock absorbers can result in excessive bouncing, swaying, or dipping, especially when driving over bumps or during braking and acceleration. Noises from the suspension, particularly from the corners of the vehicle, can also indicate shock absorber problems. Replacing worn shock absorbers improves ride comfort, handling, and braking performance.

8. Wheels and Tires

Wheels and tires are arguably the most fundamental undercarriage components, as they are the vehicle’s direct contact points with the road. They support the entire weight of the vehicle, facilitate movement, and contribute significantly to handling, braking, and overall safety.

Tires are available in various constructions, including traditional tube-type and modern tubeless designs. Tire tread patterns are designed to provide grip and prevent slippage. Regular tire inspection and maintenance are paramount. Worn or bald tires significantly increase the risk of skidding, especially in wet conditions, and should be replaced immediately to ensure safety.

Undercarriage Service and Detailing Costs

Given the complexity and vital functions of the undercarriage, regular servicing is essential. The cost of undercarriage detailing or repair varies depending on the specific component requiring attention. For a general reference, here’s an estimated cost breakdown for servicing common undercarriage parts:

| Component | Estimated Costs (IDR) | Estimated Costs (USD) |

|---|---|---|

| Tie Rod | IDR 300,000 – 340,000 | USD 20 – 23 |

| Bushing Arm | IDR 300,000 – 350,000 | USD 20 – 24 |

| Ball Joint | IDR 90,000 – 150,000 | USD 6 – 10 |

| Link Stabilizer | IDR 40,000 – 45,000 | USD 3 – 3 |

| Front Wheel Bearing | IDR 150,000 – 160,000 | USD 10 – 11 |

| Rear Wheel Bearing | IDR 80,000 – 90,000 | USD 5 – 6 |

Please note: These costs are estimates and can vary based on location, vehicle make and model, and the specific repair shop. (USD conversions are approximate and based on current exchange rates).

When it comes to undercarriage service, choosing a reputable and qualified repair shop is crucial. For Wuling car owners, authorized service centers offer specialized expertise and genuine parts, ensuring quality service and maintaining your vehicle’s warranty.

Authorized service centers, like Wuling’s official workshops, often provide benefits such as:

- Warranty on parts and labor

- Scheduled maintenance packages

- Genuine OEM (Original Equipment Manufacturer) parts

- Trained technicians specializing in your vehicle brand

Conclusion:

Maintaining your car’s undercarriage is not just about comfort; it’s about safety and the longevity of your vehicle. Regular inspections and timely servicing of undercarriage parts are essential for ensuring optimal handling, ride quality, and overall driving safety. Whether you choose an authorized dealer or a trusted independent mechanic, prioritize regular undercarriage maintenance to keep your car running smoothly and safely for years to come.