That moment of dread when a crucial car part, weathered by years or simply brittle with age, crumbles into pieces is all too familiar for car enthusiasts. Sourcing replacements, especially for classic or less common vehicles, can be a costly and frustrating treasure hunt. What if you could conjure up a perfect replica with the push of a button, much like a Star Trek replicator? While not quite teleportation magic, 3D printing is revolutionizing how we approach car part replacement and customization, and finding the Best 3d Printer For Making Car Parts is now within reach for home mechanics and hobbyists.

Imagine fabricating interior trim pieces, custom brackets, or even specialized tools, all from the comfort of your garage. With a 3D printer and the vast resources of online 3D model repositories, this is not just a futuristic fantasy, but a practical reality. From crafting cold-air intakes to designing bespoke bodywork, and even creating tools tailored for specific repair jobs, the possibilities are truly expansive. The only true limits are your creativity and your growing proficiency in the world of 3D modeling.

Consumer-grade 3D printers have matured significantly over the past decade, driving down costs and increasing accessibility. A reliable 3D printer capable of producing quality car parts can now be acquired for under $300, making it an invaluable addition to any well-equipped garage or workshop. This guide will walk you through the essentials of getting started with 3D printing car parts and help you identify the best 3D printer for making car parts for your needs.

Choosing the Right 3D Printer for Automotive Parts

For beginners venturing into the world of 3D printing car parts, Fused Deposition Modeling (FDM) printers stand out as the most accessible and practical entry point. This guide will focus on FDM technology because it represents the best 3D printer for making car parts for hobbyists and DIYers due to its affordability and ease of use.

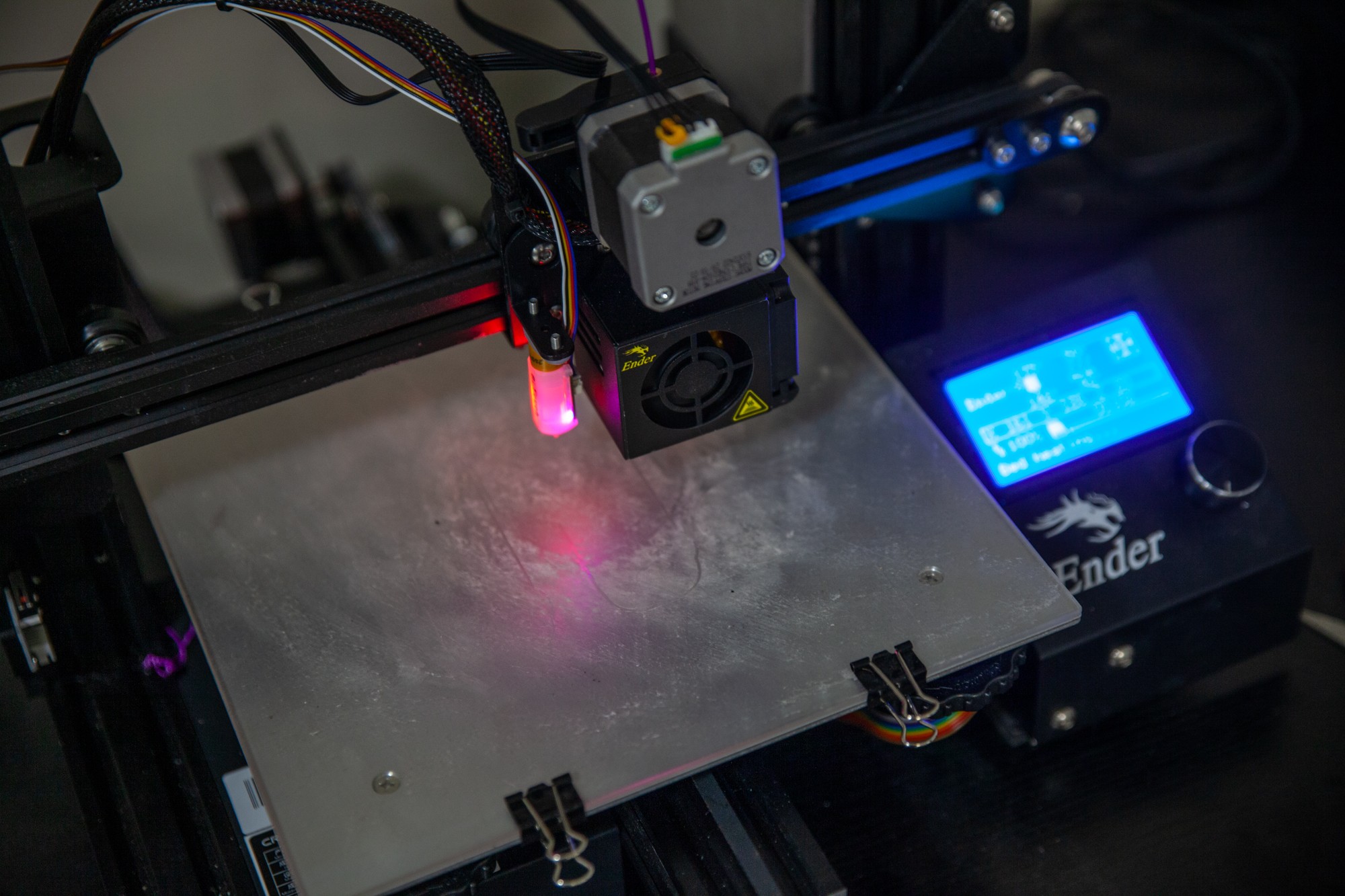

FDM printers operate by extruding molten plastic filament through a heated nozzle onto a build platform. The printer meticulously builds your design layer by layer, precisely following the digital blueprint you provide. Within the FDM category, a diverse range of brands and models are available. A popular and budget-friendly choice is the Creality Ender-3.

Entry-Level FDM Printers: Top Recommendations

The Creality Ender-3 has earned its reputation as a fantastic entry-level option due to its attractive price point (around $200) and a vibrant, supportive online community. While assembly can be a bit intricate with the Ender-3, the wealth of online resources, including assembly guides and troubleshooting tips from fellow users, more than compensates. This community also offers a treasure trove of recommendations for aftermarket upgrades, such as glass print beds for enhanced print surface consistency or auto-leveling sensors to simplify bed leveling.

For those seeking a more streamlined, “plug-and-play” experience, the Prusa Mini+ and Flashforge Finder 3 are excellent alternatives. While these models typically come with a slightly higher price tag (around $400), they often offer simplified setup and user-friendly interfaces, making them appealing options for beginners who prioritize ease of use without compromising print quality for car part creation. These are considered by many to be among the best 3D printers for making car parts in the slightly higher budget range for beginners.

Key Features to Consider

When selecting the best 3D printer for making car parts, consider these key features:

- Build Volume: Think about the size of the car parts you intend to print. Larger build volumes allow for printing bigger parts in a single piece.

- Print Quality: Look for printers with good resolution and accuracy to ensure your car parts have a smooth finish and precise dimensions.

- Reliability: A reliable printer minimizes frustration and ensures consistent results, especially important for complex car part prints.

- Material Compatibility: Confirm the printer is compatible with the types of filaments suitable for car parts, such as ABS and PETG (discussed below).

- Price: Balance your budget with the features and quality you need. Entry-level printers offer excellent value for beginners.

Choosing the Right Materials for 3D Printed Car Parts

Once you’ve chosen your printer, the next crucial step is selecting the right filament. The market offers a vast array of colors and materials, but for car parts, three main types of plastic filament are commonly used with entry-level FDM machines: PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol-modified). Each has unique properties, making them suitable for different automotive applications.

PLA is a popular choice for initial prototypes and mock-ups due to its affordability (around $20 per kg roll) and ease of printing. It’s readily available from numerous retailers. However, PLA’s weaknesses lie in its poor heat and UV resistance, making it unsuitable for under-hood components or exterior parts exposed to direct sunlight.

ABS filament offers superior strength, heat resistance, and wear resistance, making it a better option for many automotive applications. Its cost is comparable to PLA. However, ABS can be more challenging to print due to its tendency to warp and shrink as it cools, requiring careful print settings and sometimes an enclosure for the printer.

PETG strikes a balance between PLA and ABS. It’s easier to print than ABS, yet stronger and more durable than PLA, offering good heat and chemical resistance. As expected, PETG comes at a slightly higher price point, but its versatility often justifies the cost for durable car parts. For many, PETG is considered the best 3D printer material for car parts when considering ease of use and durability.

Finding and Creating 3D Models for Your Car

With your printer and materials ready, you need 3D models to print. Thingiverse is an excellent starting point – a vast online repository of free, downloadable 3D models. Other platforms like GrabCAD and Thangs also offer extensive libraries. If you own a popular vehicle like a Miata or BMW 3 Series, you’ll likely find a wealth of pre-designed parts, ranging from door panel repair kits and brake cooling ducts to pedal spacers and custom trim pieces.

If you can’t find a pre-made model for your specific need, you’ll need to embark on 3D modeling yourself. Fortunately, free software like Fusion 360 (free for personal, non-commercial use) and numerous online tutorials are available to guide you. Learning 3D modeling expands your capabilities immensely, allowing you to create truly custom car parts and overcome design limitations.

The 3D Printing Process: From Model to Physical Part

Before your printer can bring your digital design to life, you need to convert the 3D model into a language it understands – GCODE. This is where slicer software comes in. You import your 3D model into the slicer program, specify your filament material, adjust print settings like layer height and infill density to fine-tune print quality and speed. The slicer then translates your design into GCODE, which you can export to your printer via SD card or USB. Then, simply initiate the print and watch as your car part materializes layer by layer.

The satisfaction of holding a car part you designed and printed yourself is immense, especially when the alternative is costly replacements or laborious fabrication. With the right best 3D printer for making car parts and a bit of practice, you can unlock a new realm of automotive DIY possibilities. So, embrace the world of 3D printing and start creating!