Carbon fiber and black plastic trim are increasingly common on modern vehicles, adding a touch of sporty elegance. However, these parts, while durable, are not immune to the elements and can lose their luster over time, becoming swirled, hazy, or faded. Fortunately, restoring their deep black shine is achievable with the right techniques and products. You don’t need exotic tools or methods; polishing your car’s black parts, including carbon fiber, is similar to caring for your car’s paint.

For most carbon fiber and black plastic trim, the clear coat or surface finish is often softer than automotive paint. This means a gentle approach is key. Starting with the least aggressive methods and gradually increasing intensity ensures you achieve the desired results without causing further damage.

Let’s explore how to effectively polish your car’s black parts, focusing on carbon fiber and plastic trim, to bring back that showroom shine.

Understanding Car Black Parts: Carbon Fiber and Trim

“Car black parts” broadly refers to exterior and interior components finished in black. This often includes:

- Carbon Fiber: Hoods, spoilers, mirror caps, interior trim panels, and more. Carbon fiber is known for its strength and lightweight properties, often finished with a clear coat for gloss and protection.

- Plastic Trim: Bumpers, side skirts, window surrounds, door handles, and various interior trim pieces. These are typically textured or smooth plastic, often prone to fading and weathering.

Both materials, while distinct, share the common challenge of maintaining a rich, deep black appearance. Polishing plays a crucial role in restoring and enhancing their aesthetic appeal.

Why Polish Car Black Parts? Benefits of Polishing

Polishing car black parts, especially carbon fiber and plastic trim, offers several key benefits:

- Swirl and Scratch Removal: Like paint, clear-coated carbon fiber and smooth plastic trim can develop swirl marks and fine scratches from washing and daily use. Polishing gently removes these imperfections, restoring a smooth, flawless surface.

- Gloss Enhancement: Polishing refines the surface, increasing light reflection and resulting in a deeper, richer gloss. This is particularly noticeable on carbon fiber, enhancing its visual depth and weave pattern.

- Haze and Oxidation Removal: Over time, black plastic trim can become hazy or develop a white, oxidized layer due to UV exposure. Polishing removes this oxidation, bringing back the original deep black color.

- Restoration and Revitalization: Polishing breathes new life into tired-looking black parts, making them appear newer and more vibrant, enhancing the overall look of your vehicle.

- Preparation for Protection: A polished surface provides the ideal base for applying waxes, sealants, or ceramic coatings. These protective layers bond better to a clean, smooth surface, offering longer-lasting shine and protection.

How to Polish Car Black Parts: A Step-by-Step Guide

Polishing car black parts, whether carbon fiber or plastic trim, follows a similar process to paint correction, but with a focus on gentler methods. Here’s a step-by-step guide:

-

Wash and Dry Thoroughly: Begin by washing the black parts using a pH-neutral car soap and the two-bucket method. This removes loose dirt and grime. Rinse thoroughly and dry with a microfiber drying towel. Ensure the surface is completely clean and dry before proceeding.

-

Inspect the Surface: Examine the black parts under good lighting to assess the severity of swirls, scratches, or oxidation. This will help determine the level of polishing needed.

-

Choose the Right Polish and Pad: For most black parts, especially carbon fiber with a softer clear coat, start with a fine polishing compound and a soft foam polishing pad.

- Polishes: Consider fine polishes like Meguiars M205 Ultra Finishing Polish or Menzerna 106FA Super Finish. These are effective at removing light imperfections and enhancing gloss without being overly abrasive.

- Pads: Use soft foam pads like Lake Country Black Finishing Pad or Tangerine Ultra Fine Polishing Pad. These pads are gentle and ideal for finishing and light defect removal on delicate surfaces.

-

Tape Off Surrounding Areas: Protect adjacent paint, trim, or rubber seals by taping them off with painter’s tape. This prevents polish residue from staining or getting into crevices.

-

Apply Polish: Apply a few drops of polish onto the polishing pad. Work in a shaded area and ensure the surface is cool to the touch.

-

Polish the Surface: Using a dual-action (DA) polisher or by hand, work the polish into the black part in overlapping motions.

- DA Polisher: Set the polisher to a low to medium speed. Apply light to moderate pressure and work in sections, typically 2×2 feet. Make several passes over each section until the polish becomes almost clear.

- Hand Polishing: Apply moderate pressure and use small, circular motions, working in small sections. Hand polishing requires more effort but offers precise control.

-

Wipe Off Residue: After polishing a section, wipe off the polish residue with a clean microfiber towel. Inspect the area to check for defect removal and gloss improvement.

-

Repeat if Necessary: If deeper scratches or swirls remain, you can try a slightly more aggressive polish or pad combination. However, always start with the least aggressive method and gradually increase as needed. For heavily oxidized plastic trim, a dedicated plastic restorer polish might be beneficial.

-

Final Wipe Down: Once you are satisfied with the polishing results, do a final wipe down of all polished black parts with a detailing spray or isopropyl alcohol (IPA) to remove any remaining polish residue and prepare the surface for protection.

-

Protect with Sealant or Wax: To maintain the polished shine and protect the black parts from future degradation, apply a high-quality wax, sealant, or ceramic coating. This will add gloss, provide UV protection, and make future cleaning easier. For plastic trim, consider a trim-specific protectant.

Polishing Carbon Fiber: Ferrari F430 Scuderia Example

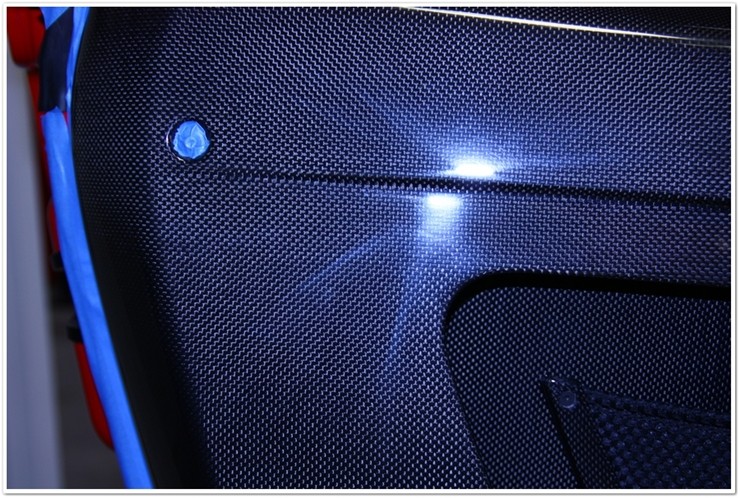

Even high-performance vehicles with exotic materials like carbon fiber are susceptible to swirl marks and hazing. A Ferrari F430 Scuderia, despite being relatively new with only 800 miles, showcased factory-induced swirls and haze on its carbon fiber door panels.

Before polishing, the carbon fiber appeared hazy and lacked depth. Under inspection lights, the severity of the swirls and holograms became evident.

Alt text: Severely swirled and hazy carbon fiber door panel of a Ferrari F430 Scuderia before polishing, showing holograms and lack of clarity.

To restore the carbon fiber, a gentle polishing approach was employed:

- Cleaning: The surface was first cleaned with a spray bottle containing Optimum No Rinse (ONR) and dried to remove any surface contaminants.

- Taping: Trim and mounting hardware were taped off to protect them from polish.

- Polishing: Meguiars M205 Ultra Finishing Polish was used with a 4″ Tangerine Hydro-Tech polishing pad on a Porter Cable 7424XP DA polisher. The Tangerine pad offers slightly more cut than a white pad but finishes down almost as well as a black pad, making it ideal for delicate carbon fiber clear coats.

Alt text: Polishing carbon fiber door panel of a Ferrari F430 Scuderia with Meguiars M205 and a Tangerine Hydro-Tech pad using a Porter Cable DA polisher.

After just one pass of polishing, a significant improvement was visible. Approximately 95% of the defects were removed, and the carbon fiber’s color and clarity were dramatically enhanced.

Alt text: Ferrari F430 Scuderia carbon fiber door panel after polishing with Meguiars M205, showing significant improvement in clarity and swirl removal, before sealant application.

To further enhance the gloss and add protection, Blackfire Wet Diamond sealant was applied after wiping down the polished surface with Meguiars M34 Final Inspection to remove polish residue.

Alt text: Applying Blackfire Wet Diamond sealant to the polished carbon fiber door panel of a Ferrari F430 Scuderia to enhance gloss and provide durable protection.

The final result was a stunning transformation, with the carbon fiber exhibiting deep gloss and clarity, showcasing its intricate weave and rich black color.

Alt text: Finished and restored carbon fiber door panel of a Ferrari F430 Scuderia after polishing and sealant application, displaying a deep, swirl-free shine and enhanced carbon fiber weave.

Maintaining Your Polished Black Parts

Once you’ve achieved the desired results, maintaining your polished black parts is crucial to preserve their appearance.

- Regular Washing: Wash your car regularly using pH-neutral car soap to prevent dirt and grime buildup.

- Gentle Drying: Dry black parts with soft microfiber towels to avoid introducing new swirl marks.

- Apply Wax or Sealant Regularly: Reapply wax or sealant every few months to maintain protection and gloss.

- Avoid Harsh Chemicals: Do not use harsh chemicals or abrasive cleaners on polished black parts, as they can damage the finish.

- Clay Bar Treatment: Use a clay bar a couple of times a year to remove embedded contaminants, just as you would on your car’s paint.

Conclusion

Polishing your car’s black parts, including carbon fiber and plastic trim, is a rewarding process that can dramatically improve your vehicle’s appearance. By using gentle techniques, the right products, and taking a methodical approach, you can safely remove imperfections, restore gloss, and protect these stylish components. Don’t be intimidated by carbon fiber or delicate black trim – with the right care, they can look their absolute best, enhancing the overall beauty of your car. Just remember to be gentle, use fine polishes and pads, and enjoy the stunning results!