Belts may seem like simple components, but they are indispensable for the smooth operation of your engine. Essentially, a car belt part is responsible for powering critical systems and components within the engine, ensuring everything works in harmony. The number and types of Car Belt Parts in your engine depend largely on its design and age. Let’s explore some of the most common and crucial car belt parts you’ll find under the hood.

Types of Car Belts: Understanding Key Car Belt Parts

Your vehicle relies on several types of belts, each serving a specific function. Understanding these different car belt parts is key to proper vehicle maintenance.

1. Timing Belts: The Engine Synchronizer

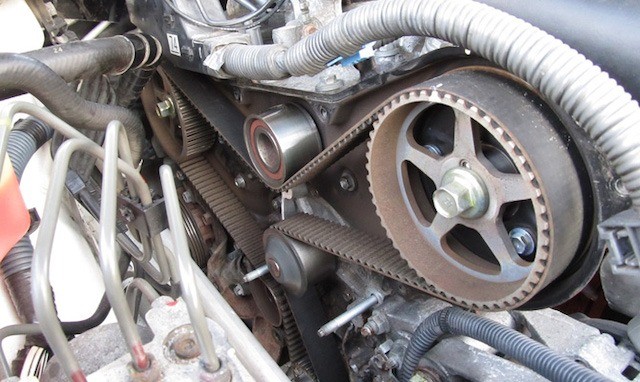

Often located under the timing cover at the front of the engine, the timing belt is a toothed belt that, in many modern vehicles, is sometimes replaced by a chain. This vital car belt part connects the crankshaft and camshaft via pulleys. Historically known as a gilmer drive belt, the timing belt performs two critical tasks. Firstly, it drives the engine’s camshaft. Secondly, and perhaps more importantly, it maintains precise synchronization between the camshaft and crankshaft. This synchronization is crucial for ensuring that the engine valves open and close at exactly the right moments during the combustion cycle. Hence the name “timing belt” – it precisely times the valvetrain.

Timing belts typically have a lifespan of around 90,000 miles, although some can last up to 110,000 miles. Interestingly, water pumps often have a similar lifespan. It is widely recommended to replace both the timing belt and water pump simultaneously. Even if the water pump seems to be functioning correctly, preventative replacement is wise, as it is likely to fail before the next timing belt replacement interval. Considering a timing belt and water pump kit can streamline this maintenance. For those considering a DIY approach, numerous resources offer helpful tips for timing belt and water pump replacement, ensuring the job is done effectively.

2. Fan Belts: Cooling System Essentials

The engine’s cooling system needs power to operate, and in some engines, this is provided by a dedicated fan belt. In other designs, the serpentine belt handles this role. The fan belt, as a key car belt part in the cooling system, can power several components, including:

- Water pump (if not powered by the serpentine belt)

- Radiator fan

- Air conditioning compressor (in some configurations)

By powering these components, a properly functioning fan belt is essential for:

- Cooling the radiator, dissipating heat from the coolant.

- Circulating coolant throughout the engine block and head, maintaining optimal engine temperature.

A broken fan belt means the engine’s cooling system is compromised, leading to potential engine overheating and potentially severe and costly engine damage. Regular inspection of the fan belt is therefore a crucial part of routine vehicle maintenance.

3. Alternator Belts: Powering the Electrical System

If a serpentine belt is not used to drive the alternator, then the engine will utilize a separate alternator belt. This is typically a smaller car belt part dedicated solely to powering the alternator. In some engine designs, the alternator belt might also power the power steering pump. The alternator belt is critical because without it, the alternator cannot function, and the car’s battery will not be recharged while the engine is running. This will lead to a dead battery and a non-operational vehicle.

4. Serpentine Belts: The Multi-Tasking Belt

Historically, engines used multiple belts, often V-belts, to power individual components. V-belts are characterized by their V-shaped cross-section that fits into matching V-shaped pulleys. The advent of the serpentine belt revolutionized engine design. Also known as the accessory belt or drive belt, the serpentine belt is a long, snaking belt that routes through multiple pulleys, powering a range of engine accessories. The “serpentine” name comes from its winding path around these pulleys.

Serpentine belts are usually located at the front or side of the engine and are ribbed to increase their contact surface with pulleys. These ribs enhance grip and allow for efficient power transmission. Driven by the crankshaft, the serpentine belt powers essential engine accessories, such as:

- Power steering pump

- Water pump (in many modern vehicles)

- Alternator (in many modern vehicles)

- Air conditioning compressor

Serpentine belts generally last between 60,000 and 100,000 miles. However, like other car belt parts, they should be included in routine vehicle inspections. Serpentine belts can experience premature wear, cracking, fraying, or even breakage. Failure of the serpentine belt will result in the immediate loss of power to all the accessories it drives, potentially leading to vehicle breakdown and the need for towing.

Evolution of Car Belt Parts Over Time

Car belt parts have undergone significant evolution alongside engine technology, driven by the need for improved performance, durability, and efficiency. Key changes include:

- Size and Design: Serpentine belts are considerably longer and wider than the older V-belts they often replaced, allowing them to drive multiple accessories.

- Material Advancement: Improvements in belt materials have significantly increased longevity and resistance to wear, heat, and cracking. Modern belts are made from robust synthetic rubber compounds.

- Profile Changes: The narrow, deep V-belt design has evolved into wider, flatter belts with multiple ribs (serpentine belts), improving grip and power transmission.

- Consolidation: The move from multiple V-belts to a single serpentine belt in newer engines simplifies engine design, reduces maintenance points, and improves overall system efficiency.

Today’s car belt parts are more reliable and durable than ever, reflecting decades of engineering advancements. Regular inspection and timely replacement of these components are crucial for maintaining vehicle reliability and preventing costly breakdowns.