For any vehicle, the brake system is undeniably one of the most critical safety features. It’s a complex assembly of parts working in perfect harmony to ensure you can slow down or stop your car effectively and safely. As a car owner, understanding the Brake Parts On A Car is not just a matter of technical curiosity; it’s essential knowledge that can empower you to recognize potential issues, communicate effectively with mechanics, and make informed decisions about maintenance and repairs.

Why is it important for a driver to be familiar with the components of their car’s braking system, even without being a mechanic? Firstly, it provides a fundamental understanding of how your car decelerates and stops, enhancing your driving awareness. Secondly, this knowledge can be economically beneficial. By understanding the function and potential issues of each component, you can better assess repair estimates and ensure you’re spending wisely on necessary maintenance.

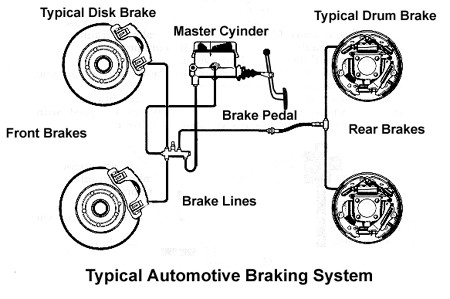

This guide will delve into the major brake parts on a car, exploring both disc and drum brake systems, along with essential hardware and accessories.

Chapter 1: Exploring the Components of a Disc Brake System

Disc brakes are the most common type of braking system in modern vehicles, particularly for front wheels where the majority of braking force is applied. They offer excellent stopping power and heat dissipation. Let’s examine the key brake parts within a disc brake system:

– Brake Pads

Brake pads are fundamental friction components in a disc brake system. These block-like structures are designed to press against the brake rotor when you apply the brakes. This friction converts kinetic energy into heat, slowing down the wheel’s rotation and ultimately stopping the vehicle.

Brake pads consist of a metal backing plate and a friction material lining. This lining is engineered to create high friction against the rotor. It’s crucial to understand that brake pad linings wear down over time due to friction. This wear necessitates regular inspection and eventual brake pad replacement.

Different types of brake pads are available, varying in their composition and performance characteristics. Common materials include:

- Organic Brake Pads: Softer, quieter, and produce less dust, but wear out faster.

- Semi-Metallic Brake Pads: A blend of metal and organic materials, offering a good balance of performance and durability.

- Ceramic Brake Pads: Offer excellent performance, low noise, and produce minimal dust, but are generally more expensive.

– Brake Rotor

The brake rotor, sometimes referred to as a brake disc, is another critical brake part in this system. It’s a circular metal component that rotates with the wheel. The rotor provides the surface against which the brake pads are pressed.

When you apply the brakes, the brake pads clamp onto the rotor, generating friction that slows the rotor and, consequently, the wheel. Like brake pads, brake rotors are subject to wear. Over time, they can become thinner, warped, or scored. Regular inspection is necessary, and brake rotor replacement is required when the rotor reaches its minimum thickness specification or exhibits damage.

– Brake Caliper

Brake calipers are responsible for actuating the brake pads. They function as clamps that house the brake pads and contain pistons. When you press the brake pedal, hydraulic pressure is applied to the caliper pistons. These pistons then push the brake pads against the rotor to initiate braking. When the brake pedal is released, the calipers retract the pads away from the rotor.

There are two primary types of brake calipers:

- Fixed Calipers: These calipers are mounted rigidly and have pistons on both sides of the rotor.

- Floating Calipers: These calipers are more common and move or “float” relative to the rotor. They typically have pistons on only one side, and the caliper body slides to apply pressure evenly.

Brake calipers are durable, but they can develop issues, particularly leaks in the hydraulic seals, which can compromise braking performance. Leaking brake fluid is a sign that brake caliper service or replacement may be needed.

Chapter 2: Understanding Drum Brake System Components

While disc brakes are prevalent on front wheels, drum brakes are still utilized in many modern vehicles, often on the rear wheels. Drum brakes are enclosed systems, offering protection from debris and often being more cost-effective than disc brakes. Let’s explore the essential brake parts of a drum brake system:

– Brake Shoes

In a drum brake system, brake shoes perform a similar function to brake pads in disc brakes. Brake shoes are curved components lined with friction material. When braking is initiated, these shoes are forced outwards against the inside surface of the brake drum.

Brake shoes consist of a metal shoe and a friction lining. This lining, similar to brake pads, wears down over time due to friction against the rotating drum. Consequently, brake shoe replacement is a routine maintenance item.

– Brake Drum

The brake drum is a cylindrical metal component that rotates along with the wheel. It’s analogous to the brake rotor in a disc brake system, but instead of being clamped externally, the braking action occurs internally. The inner surface of the brake drum is where the brake shoes make contact.

When the brake shoes are pressed outwards against the brake drum’s inner surface, friction is generated. This friction slows the rotation of the drum and the attached wheel, bringing the vehicle to a stop. Like rotors, brake drums can wear, become scored, or warped due to heat and friction. Warped or damaged drums require replacement.

– Backing Plate

The backing plate is a stationary component that provides a foundation for all other drum brake parts. It’s a rigid plate that supports the brake shoes, wheel cylinder, springs, and other hardware within the drum brake assembly. The backing plate keeps all the drum brake components correctly positioned and protected within the wheel assembly.

Chapter 3: Essential Brake System Hardware and Accessories

Image illustrating various brake hardware components, including springs and clips.

Beyond the major components of disc and drum brakes, there’s a range of brake parts that are crucial for the overall function and efficiency of the brake system. These are often referred to as brake hardware and accessories:

– Return Springs

Return springs are specifically used in drum brake systems. Their function is to retract the brake shoes back to their resting position, away from the brake drum, once the brake pedal is released. These springs ensure that the brakes are not dragging when not in use, preventing unnecessary wear and fuel inefficiency.

– Wheel Cylinder

The wheel cylinder is another component specific to drum brake systems. It’s a hydraulic cylinder located within the drum brake assembly. The wheel cylinder contains pistons that, when hydraulic pressure is applied, push the brake shoes outwards against the brake drum. Like calipers, wheel cylinders can leak brake fluid over time, requiring wheel cylinder replacement.

– Anti-Lock Braking System (ABS)

The Anti-lock Braking System (ABS) is a vital safety accessory found in most modern vehicles. It’s designed to prevent wheel lock-up during hard braking or on slippery surfaces. ABS works by monitoring wheel speed and automatically modulating brake pressure to individual wheels. If a wheel is detected to be locking up, ABS will momentarily reduce brake pressure to allow the wheel to regain traction. This prevents skidding, maintains steering control during emergency braking, and generally shortens stopping distances.

Chapter 4: Types of Brake Systems: System vs. Components

It’s important to differentiate between brake system types and brake components. The term “brake system” often refers to the overall method of braking, while “brake components” are the physical parts we’ve discussed.

Brake systems can be categorized based on their operating principles:

- Electromagnetic Braking System: Utilizes electric motors and magnetic force to slow or stop a vehicle. Often used in electric vehicles and hybrid regenerative braking systems.

- Hydraulic Brake System: The most common type in cars and light trucks. It uses hydraulic fluid pressure to transmit force from the brake pedal to the brake components at the wheels (calipers or wheel cylinders).

- Mechanical Brake System: Relies on mechanical linkages, such as levers and cables, to actuate the brakes. Historically common, now mainly used in parking brakes.

- Servo Brake System (Vacuum Assisted): Enhances hydraulic brake systems by using vacuum pressure from the engine intake manifold to amplify braking force, making it easier for the driver to apply the brakes.

Within these systems, the two main types of brakes themselves, in terms of physical mechanism, are disc brakes and drum brakes, as detailed in previous chapters. Both types operate on the principle of friction to convert kinetic energy into heat and slow the vehicle. While their designs and constructions differ, both require maintenance and replacement of worn brake parts to ensure continued safe operation.

Conclusion

Understanding the brake parts on a car is crucial for every vehicle owner. From brake pads and rotors in disc systems to shoes and drums, and essential hardware like calipers, wheel cylinders, and ABS, each component plays a vital role in your car’s ability to stop safely. Front brakes typically handle a greater proportion of the braking force compared to rear brakes.

By gaining familiarity with these components, you’ll be better equipped to understand your car’s braking system, recognize potential problems early, and communicate effectively with automotive professionals. Whether it’s diagnosing noises, understanding maintenance needs for brake pads, brake rotors, brake shoes, or any other brake parts, this knowledge contributes to safer driving and responsible car ownership.