Car Lift Cylinder: Understanding the Heart of Your Automotive Lift

Imagine this: you’re at a busy auto repair shop, a customer’s car needs to be lifted for repairs. The mechanic activates the lift, and suddenly, a loud bang! The lift fails, leaving the car precariously hanging mid-air. What went wrong? It could be a problem with the Car Lift Cylinder, a critical component responsible for lifting and lowering vehicles. This article will delve into the world of car lift cylinders, exploring their workings, common issues, and what you can do to keep your lift operating smoothly.

What is a Car Lift Cylinder?

The car lift cylinder is the hydraulic muscle that powers automotive lifts. It’s essentially a large hydraulic cylinder that uses pressurized fluid to push a piston, which in turn raises or lowers the lift platform. Imagine it as a giant syringe, where the fluid acts as the plunger and the piston is the needle.

These cylinders are typically found in two-post, four-post, and scissor lifts, and they are essential for safely and efficiently lifting heavy vehicles. They are also used in car jacks, although on a smaller scale.

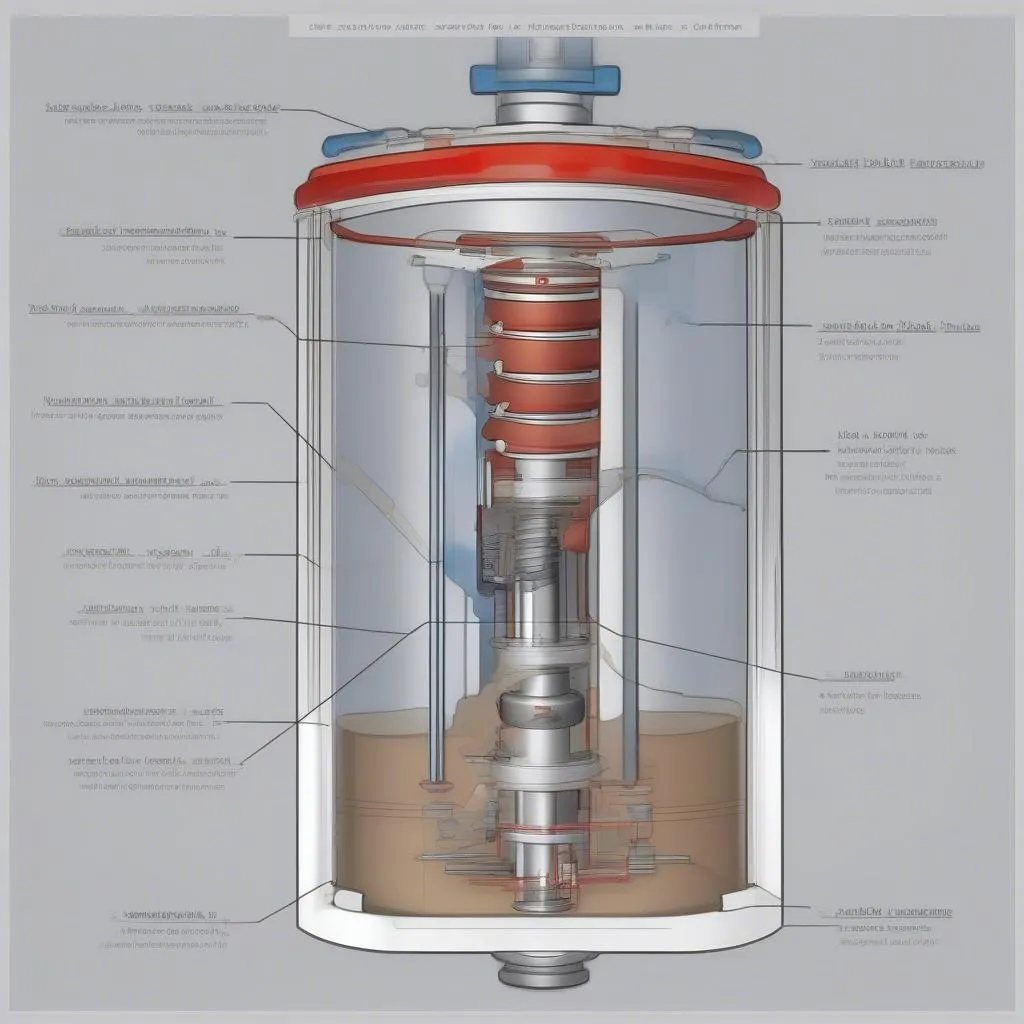

Anatomy of a Car Lift Cylinder

Car Lift Cylinder Anatomy

Car Lift Cylinder Anatomy

A car lift cylinder consists of several key components:

- Cylinder: The main housing of the cylinder, which holds the piston and hydraulic fluid.

- Piston: A movable component within the cylinder that is pushed by the hydraulic fluid.

- Seal: A rubber ring that prevents leaks between the piston and the cylinder wall.

- Rod: A solid rod connected to the piston, extending out of the cylinder and used to raise or lower the lift platform.

- Hydraulic Fluid: A specialized fluid that transmits pressure from the pump to the cylinder.

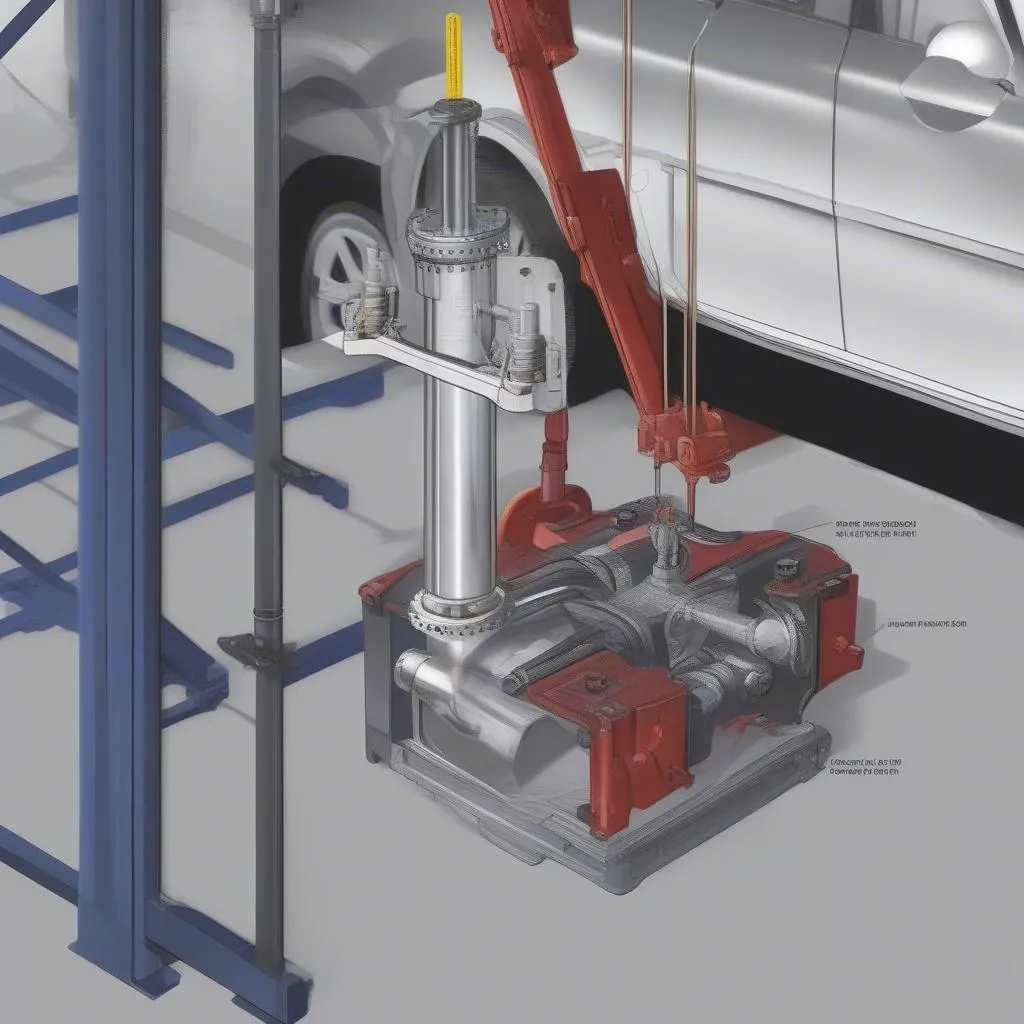

Understanding the Operation of a Car Lift Cylinder

Car Lift Cylinder Operation

Car Lift Cylinder Operation

The operation of a car lift cylinder is fairly simple, but it relies on the precise coordination of several components. Here’s a breakdown of how it works:

- Fluid Pumping: A hydraulic pump generates pressure and sends the hydraulic fluid to the cylinder.

- Fluid Direction: Valves direct the fluid into the cylinder’s chamber, pushing the piston upward.

- Platform Lifting: The piston’s upward movement is transmitted to the rod, which in turn raises the lift platform.

- Lowering the Platform: To lower the platform, the valves redirect the fluid to the other side of the piston, forcing it downward.

Common Car Lift Cylinder Issues

As with any mechanical system, car lift cylinders can experience issues over time. Some of the most common problems include:

- Leaks: A damaged seal or wear and tear on the cylinder can lead to leaks, reducing hydraulic pressure and affecting lift performance.

- Fluid Contamination: Debris or water in the hydraulic fluid can cause wear and tear on the cylinder, leading to malfunctions.

- Cylinder Wear: The cylinder walls can wear down over time, reducing efficiency and increasing the risk of leaks.

- Rod Bending or Breaking: Improper usage or overloading can lead to bending or breakage of the rod, rendering the lift unusable.

Signs of a Failing Car Lift Cylinder

Recognizing the signs of a failing car lift cylinder is essential for preventing accidents and ensuring the safety of your technicians and customers. Here are some red flags to look out for:

- Slow Lifting or Lowering: If the lift takes longer than usual to raise or lower, it could indicate a problem with the hydraulic system, including the cylinder.

- Uneven Lift: If the lift platform doesn’t rise evenly, it might point to a faulty cylinder or a problem with the hydraulic fluid.

- Noises During Operation: Unusual noises like banging, grinding, or whining during operation could indicate problems with the cylinder, seals, or other components.

- Fluid Leaks: Any visible hydraulic fluid leaks should be investigated promptly as they can signal a more serious problem.

- Platform Dropping: If the platform drops unexpectedly, it’s a serious issue that requires immediate attention and could indicate a major failure in the cylinder or other hydraulic components.

Maintaining Your Car Lift Cylinder

Regular maintenance is crucial to extend the life of your car lift cylinder and prevent costly repairs. Here are some tips for keeping your cylinder in top shape:

- Regular Inspections: Inspect the cylinder for any signs of wear, leaks, or damage regularly.

- Hydraulic Fluid Maintenance: Check the hydraulic fluid level and quality, replacing it as needed with the appropriate type for your lift.

- Correct Usage: Follow the manufacturer’s guidelines for using the lift correctly and avoiding overloading.

- Lubrication: Regularly lubricate the cylinder rod and other moving parts to prevent wear and tear.

Car Lift Cylinder Replacement: When to Consider It?

While regular maintenance can extend the life of a car lift cylinder, there will come a time when it needs to be replaced. If you experience any of the following, it’s likely time for a new cylinder:

- Severe Leaks: Multiple attempts at repairing leaks have failed.

- Cylinder Wear: The cylinder walls are heavily worn, leading to reduced efficiency and increased risk of failure.

- Rod Damage: The rod is bent, broken, or severely corroded.

- Regular Issues: The cylinder consistently experiences issues despite regular maintenance.

Choosing the Right Car Lift Cylinder

When replacing a car lift cylinder, it’s important to choose the right one for your lift. Consider the following factors:

- Lift Capacity: Ensure the new cylinder has a capacity that matches your lift’s specifications.

- Lift Type: Select a cylinder compatible with your lift type (two-post, four-post, scissor).

- Brand and Quality: Choose a reputable manufacturer and invest in high-quality cylinders for long-term performance.

Car Lift Cylinder: An Essential Component

Car lift cylinders are the backbone of many automotive repair shops. Understanding their function, common issues, and preventative measures can help ensure their reliable operation and contribute to a safer and more efficient work environment.

FAQs

Q: Can I repair a leaking car lift cylinder myself?

A: While some minor leaks can be addressed with replacement seals, more severe leaks often require professional repair or a cylinder replacement. It’s always best to consult with a qualified technician.

Q: How often should I change the hydraulic fluid in my car lift?

A: Refer to the manufacturer’s recommendations for your specific lift, but a general rule of thumb is to change the fluid every 6 months or 1000 hours of operation.

Q: What are some tips for extending the life of a car lift cylinder?

A: Regular inspection, correct usage, appropriate fluid maintenance, and lubrication are essential for prolonging the lifespan of your car lift cylinder.

Q: Where can I find a replacement car lift cylinder?

A: You can find replacement car lift cylinders from various automotive parts suppliers, both online and offline. Check with reputable manufacturers and distributors for compatible cylinders.

Get Expert Help with Your Diagnostics Tool

For assistance with your car lift cylinder and other diagnostics tools, reach out to our team of automotive experts at +84767531508. We offer 24/7 support and can help you troubleshoot any issues you encounter.

Remember, safety comes first! When working with car lifts, always follow proper procedures and safety guidelines. If you encounter any problems, seek professional assistance.

Don’t hesitate to explore other informative articles on our website, such as:

- Baghera Race Car: A Glimpse into Automotive Excellence

- Scissor Lift Car Hoist: A Comprehensive Guide

- Car Lift Air: Understanding Air Powered Lifts

- Full Rise Car Scissor Lift: Benefits and Applications

We encourage you to leave a comment below if you have any further questions or share your experiences with car lift cylinders.