Just like the human body, a car engine is a complex system composed of numerous parts working in harmony to generate motion. At its core, the engine’s function is to convert fuel energy into mechanical power through a process of controlled combustion. This internal combustion process creates a series of small, contained explosions that ultimately propel your vehicle. While often perceived as a single unit, the engine is actually an assembly of interconnected components, each playing a vital role. Understanding the names and functions of these car engine parts is crucial for any car owner. Let’s delve into the major components and their roles within this intricate system.

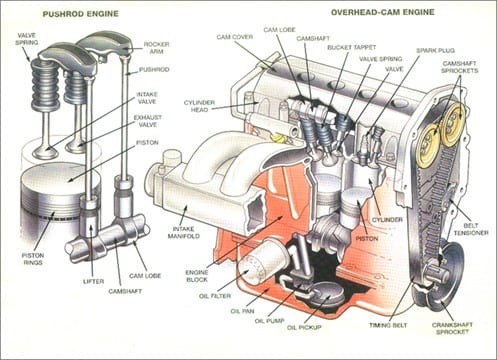

Diagram of a car engine and its parts

Diagram of a car engine and its parts

Modern car engines are built around robust, sealed metal cylinders. Most vehicles today utilize engines with four to eight cylinders, although some high-performance models can feature up to sixteen. These cylinders are meticulously designed to open and close at precise intervals, facilitating the intake of fuel and air for combustion and the expulsion of exhaust gases. While a car engine comprises many parts, we will focus on the essential components that are fundamental to its operation. Refer to the diagram above to visualize the location of these parts within the engine.

-

Engine Block: The engine block serves as the foundational structure of the engine. Typically constructed from aluminum or iron, it is cast with multiple cylindrical bores to house the cylinders. Crucially, it also incorporates intricate channels for the circulation of coolant and oil, essential for engine cooling and lubrication. Oil passages are generally narrower than coolant passages. The engine block provides housing for key components including the pistons, crankshaft, and camshaft. Depending on the vehicle and engine configuration, it can contain four to twelve cylinders arranged in various layouts such as inline, flat, or V-shaped configurations.

-

Pistons: Pistons are cylindrical components with a flat or slightly domed top surface. Their primary function is to translate the force generated by combustion into mechanical motion that drives the crankshaft and, subsequently, the vehicle. Pistons move up and down within the cylinders. In each crankshaft rotation, a piston completes two strokes (up and down). In an engine operating at 1250 RPM, each piston will reciprocate 2500 times per minute. Piston rings, located in grooves around the piston’s circumference, are vital for maintaining cylinder compression and minimizing friction as the piston moves against the cylinder walls.

-

Crankshaft: Situated in the lower section of the engine block, the crankshaft resides within crankshaft journals, supported by bearings. This precisely engineered and balanced component connects to the pistons via connecting rods. The crankshaft’s ingenious design converts the linear, reciprocating motion of the pistons into rotary motion, which is essential for powering the drivetrain. This conversion process is similar in principle to a jack-in-the-box mechanism, transforming up-and-down movement into rotational movement at engine speed.

-

Camshaft: The location of the camshaft can vary depending on the vehicle and engine design, residing either within the engine block or in the cylinder heads. Modern engines frequently employ overhead camshaft configurations, either Single Overhead Camshaft (SOHC) or Dual Overhead Camshaft (DOHC), positioned in the cylinder heads. The camshaft is supported by a series of oil-lubricated bearings for smooth operation and durability. Its crucial role is to regulate the timing of valve opening and closing. It converts the rotary motion from the crankshaft into an up-and-down motion, which is then used to control the lifters, pushrods, rockers, and ultimately, the valves.

-

Cylinder Head: The cylinder head is bolted to the engine block, sealed with a head gasket to prevent leaks. It is a complex component that houses numerous parts including valve springs, valves, lifters, pushrods, rockers, and camshafts (in overhead cam engines). The cylinder head is designed with passages that control the flow of intake air into the cylinders during the intake stroke and exhaust passages to expel combustion gases during the exhaust stroke. The precise control of these passages by the valves is critical for efficient engine operation.

-

Timing Belt/Chain: Synchronization between the camshaft and crankshaft is paramount for proper engine function, ensuring precise timing of all engine events. This synchronization is achieved by either a timing belt or a timing chain. A timing belt is typically made of durable rubber reinforced with cords and features cogs that mesh with pulleys on the camshaft and crankshaft. A timing chain, resembling a bicycle chain, wraps around toothed sprockets on the camshaft and crankshaft. Both systems maintain the critical relationship between crankshaft and camshaft rotation.

Common Engine Problems

The engine’s intricate system of rapidly moving parts can, over time, experience wear and tear, leading to various issues that affect vehicle performance. Here are some common engine problems and their associated symptoms:

- Poor Compression: This can result in reduced engine power, engine misfires, or even the inability to start the engine. Low compression indicates issues within the cylinders, such as worn piston rings or valve problems.

- Cracked Engine Block: A crack in the engine block can cause serious problems including engine overheating, white smoke emanating from the exhaust (due to coolant burning), and coolant leaks, often visible on the exterior of the engine block.

- Damaged Pistons, Rings, and/or Cylinders: Damage to these components can manifest as rattling noises from within the engine, blue smoke from the exhaust pipe (indicative of oil burning), rough engine idling, and failure to pass vehicle emissions tests.

- Broken or Worn Rods, Bearings, & Pins: Problems in these areas can produce tapping or ticking sounds, low engine oil pressure, the presence of metal shavings in the engine oil, or rattling noises specifically during acceleration.

While car engines may appear complex due to their many interconnected parts, their fundamental purpose is straightforward: to generate the power to move your vehicle. Given the intricate interplay of numerous components, regular and proper vehicle maintenance is essential to ensure engine longevity and reliable performance. Adhering to a schedule of oil changes, coolant and fluid flushes, and replacing belts and hoses at recommended intervals are crucial preventative measures that can help avoid significant engine problems and costly repairs.

Sun Auto Service specializes in comprehensive engine maintenance and repair services. When you need a trustworthy auto repair center to care for your vehicle, you want a provider committed to honest assessments and quality workmanship. Sun Auto Service prides itself on delivering both honesty and high-quality service at affordable prices. We are proud to hold an A+ rating with the Better Business Bureau and employ ASE Certified Technicians. Furthermore, our nationwide warranty provides peace of mind long after you leave our service center. Dealership-level expertise at budget-friendly prices – that’s the Sun Auto Service commitment.