A car battery is the heart of your vehicle’s electrical system. Whether you drive a traditional gasoline-powered car or a modern electric vehicle (EV), a functional battery is crucial to get you started and keep all your electrical components running smoothly. More than just a simple box, a car battery is a sophisticated energy storage unit. Upon ignition, it releases stored chemical energy as electricity, enabling your car to operate. Let’s delve into the essential “Car Battery Parts Name” and understand their roles in this vital component.

What is a Car Battery?

In essence, a car battery is a device that converts chemical energy into electrical energy. Specifically, the automotive battery is a rechargeable wet-cell battery designed to store chemical energy and instantly convert it into electricity when needed. Regardless of the vehicle type, the fundamental function remains the same: to provide power to start the engine and operate all electrical accessories.

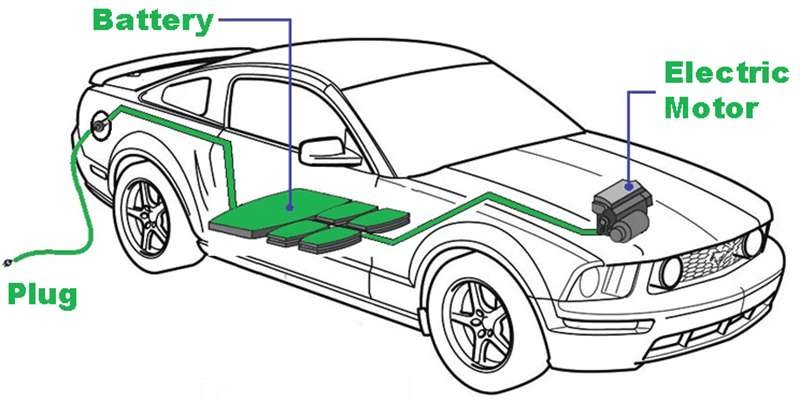

When you turn the ignition key, the battery delivers a surge of electric current. This current initiates the internal combustion process in gasoline engines or powers the electric motor in EVs. Beyond starting the engine, the battery is also essential for running various electrical systems, including headlights, interior lights, radio, windshield wipers, and more.

Exploring the Essential Car Battery Parts Name and Their Functions

While the exterior of a car battery might appear as a simple case, the internal components are what make it work. Let’s break down the “car battery parts name” and understand their individual functions:

Battery Case: The Protective Housing

The battery case is the robust outer shell that encloses all the internal components of the car battery. This case is designed to be durable and resistant to various conditions encountered under the hood of a car, such as temperature fluctuations, vibrations, and impacts.

For traditional lead-acid batteries commonly found in gasoline vehicles, the case is often made from polypropylene resins, chosen for their strength and resistance to battery acid. In electric vehicles, where battery packs can be significantly larger and more complex, the enclosure cases often utilize aluminum alloys. Aluminum offers a combination of strength, lightweight properties, and corrosion resistance, crucial for protecting the sensitive battery components within EVs. The primary function of the battery case is to safeguard the internal parts, prevent leaks of the battery electrolyte, and extend the overall lifespan of the battery by minimizing external damage.

Battery Terminals: The Connection Points

Battery terminals, sometimes referred to as battery bushings, are the crucial connection points that bridge the battery to your car’s electrical system. These terminals are designed to conduct electricity efficiently and ensure a secure connection. Every car battery has two terminals:

- Positive Terminal (+): Usually marked with a plus sign (+) and often larger than the negative terminal and may have a red cover or marking.

- Negative Terminal (-): Marked with a minus sign (-) and typically smaller, often with a black cover or marking.

These terminals are typically made of lead or lead alloys due to their excellent conductivity and resistance to corrosion. Clamps or cables are attached to these terminals to connect the battery to the car’s wiring harness. Proper maintenance of battery terminals, keeping them clean and free from corrosion, is essential for reliable electrical flow and preventing starting issues.

Battery Plates: The Power Generators

Battery plates are the core components responsible for the electrochemical reactions that generate electricity within the battery. A typical car battery contains multiple positive and negative plates submerged in the electrolyte solution.

- Positive Plates: These plates are typically made of a lead grid coated with lead dioxide (PbO2). Lead dioxide acts as the cathode during discharge and is reduced during the chemical reaction.

- Negative Plates: These plates consist of a lead grid filled with spongy lead (Pb). Spongy lead acts as the anode during discharge and is oxidized during the chemical reaction.

The number and size of battery plates directly influence the battery’s power output and capacity. A larger surface area of the plates allows for more significant chemical reactions, resulting in higher current output. These plates are carefully designed and manufactured to maximize surface area within the battery case while maintaining structural integrity.

Battery Separators: Preventing Short Circuits

Battery separators are thin, porous, non-conductive sheets placed between the positive and negative plates. Their essential role is to electrically isolate the plates from each other, preventing them from touching and causing a short circuit. At the same time, the separator must allow the electrolyte to flow freely, ensuring the electrochemical reactions can occur.

Battery separators are commonly made from materials like polyethylene or other specialized plastic polymers. These materials are chosen for their chemical inertness in the battery electrolyte, their porosity to facilitate ion transport, and their ability to withstand the battery’s operating conditions. The effectiveness of the separators is crucial for battery performance and longevity; a damaged or ineffective separator can lead to battery failure.

Electrolyte: The Reaction Medium (Battery Acid)

The electrolyte is the liquid solution that fills the battery and enables the flow of ions between the positive and negative plates, facilitating the chemical reactions that produce electricity. In traditional lead-acid car batteries, the electrolyte is a solution of sulfuric acid (H2SO4) and water, typically with a concentration of 30-50% sulfuric acid. This solution is often referred to as “battery acid.”

The sulfuric acid electrolyte reacts chemically with the materials on the battery plates. During discharge, sulfuric acid reacts with lead dioxide on the positive plate and spongy lead on the negative plate, producing lead sulfate, water, and releasing electrons, thereby generating an electric current. The concentration and purity of the electrolyte are critical for optimal battery performance. Impurities can hinder the chemical reactions and reduce battery efficiency.

Working Principles of Car Batteries: How the Parts Function Together

The car battery’s primary function is to supply the electrical current needed to start the engine and power the vehicle’s electrical systems. Even when the engine is off, it provides power to some accessories. However, the car can only be driven once the engine is started.

Here’s a simplified look at the working principle:

- Chemical Reaction: When you turn the ignition, a chemical reaction is initiated within the battery. The sulfuric acid electrolyte reacts with the lead plates, converting chemical energy into electrical energy. This process generates a voltage difference between the terminals.

- Current Flow: The voltage difference drives electrons to flow from the negative terminal, through the car’s electrical circuits, to the positive terminal. This flow of electrons is the electric current that powers the starter motor and other electrical components.

- Voltage Regulation: The battery also plays a stabilizing role by regulating voltage. It helps maintain a consistent voltage level, protecting sensitive electronic components from voltage spikes and fluctuations.

- Limited Discharge for Starting: Interestingly, starting a car typically only requires a small percentage (around 3%) of the battery’s total capacity. Car batteries are designed to deliver a high current for a short duration, primarily for starting, lighting, and ignition (SLI batteries).

Different Types of Auto Batteries: Beyond the Basic Parts

While the fundamental “car battery parts name” remain consistent across battery types, the specific materials and construction can vary. Understanding the different types of car batteries can help you make informed decisions for your vehicle:

Lead-Acid Batteries: The Traditional Choice

Lead-acid batteries are the most common type found in gasoline-powered vehicles. They are a mature technology, offering a good balance of power and cost-effectiveness. As discussed, they utilize lead plates and a sulfuric acid electrolyte. Within lead-acid batteries, there are subtypes like flooded, AGM (Absorbent Glass Mat), and EFB (Enhanced Flooded Battery), each with slight variations in construction and performance characteristics.

Lithium-Ion (Li-ion) Batteries: Powering the EV Revolution

Lithium-ion batteries are increasingly prevalent, especially in electric vehicles and hybrid cars. They offer higher energy density than lead-acid batteries, meaning they can store more energy for their size and weight. Li-ion batteries utilize different chemistries, but generally involve lithium compounds as electrodes and organic electrolytes. They enable longer driving ranges for EVs and offer advantages in terms of weight and lifespan compared to lead-acid options.

Solid-State Batteries: The Future of Battery Technology

Solid-state batteries represent a newer and promising technology. Unlike traditional batteries with liquid or gel electrolytes, solid-state batteries use a solid electrolyte material. This technology offers potential benefits such as improved safety, higher energy density, faster charging times, and longer lifespan. While still under development for widespread automotive use, solid-state batteries are considered a significant advancement in battery technology.

Functions of Car Batteries: More Than Just Starting

Car batteries perform several crucial functions beyond just starting the engine:

- Engine Starter: As the primary function, the battery provides the high current needed to crank the engine and initiate the combustion process or power the electric motor.

- Power Storage: The battery stores electrical energy, allowing the car to restart and power accessories even when the engine isn’t running. Once the engine is running, the alternator recharges the battery, replenishing the stored energy.

- Collaboration with Alternator for Electrical Components: The alternator supplies power to the car’s electrical systems while the engine is running. However, the battery acts as a buffer and supplement, especially when electrical demand exceeds the alternator’s output, such as when using power-hungry accessories or at idle.

- Voltage Regulation and System Protection: The battery helps stabilize the vehicle’s electrical system voltage. It can absorb voltage fluctuations and surges, protecting sensitive electronic components from damage.

Conclusion: Understanding Your Car Battery Parts Name for Better Maintenance

Knowing the “car battery parts name” and their functions is more than just technical knowledge; it empowers you to understand your vehicle better and perform basic maintenance. A healthy battery is essential for reliable vehicle operation. By understanding the components and how they work together, you can better diagnose potential battery issues, ensure proper maintenance, and ultimately extend the life of this critical automotive component.

FAQs

What are the basic components of a car battery?

The fundamental components include the electrolyte (battery acid in lead-acid batteries or lithium salt solutions in Li-ion), positive plates (anode), negative plates (cathode), separators, terminals, and the battery case. The case is crucial for safety and containment of the battery components.

What is the liquid inside a car battery?

In a traditional lead-acid car battery, the liquid is the electrolyte, a solution of sulfuric acid and water, often called battery acid. In lithium-ion batteries, the electrolyte is typically a solution of lithium salts in organic solvents.