The automotive world is constantly evolving, and with it, the technology that supports car enthusiasts and restorers. One of the most transformative advancements in recent years is 3D printing. While once considered a futuristic concept, 3D printing, also known as additive manufacturing, has become increasingly accessible and sophisticated. For those passionate about vintage cars, this technology is proving to be a game-changer, particularly when it comes to sourcing those elusive and often irreplaceable parts.

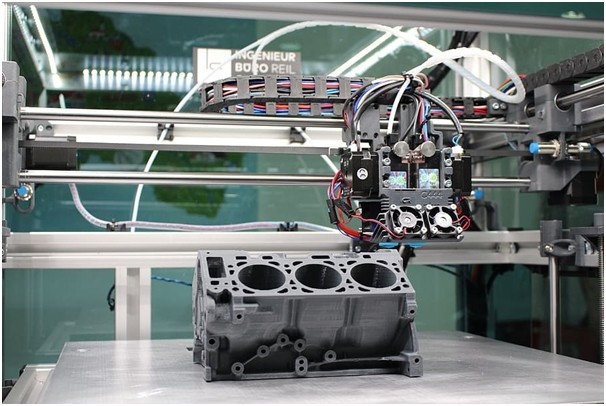

3D printing technology has matured significantly from its early days. What started as a niche method for rapid prototyping has expanded into a versatile manufacturing process utilized across diverse industries, including healthcare, aerospace, and, increasingly, automotive. Entry-level 3D printers are now available for home use at relatively affordable prices, while professional-grade equipment offers precision and material capabilities suitable for demanding applications. The fundamental principle involves building objects layer by layer from materials like plastic, resin, or even metals, guided by digital designs. This additive approach contrasts with traditional subtractive methods like machining, where material is removed to create the desired shape.

The automotive industry has been quick to recognize the potential of 3D printing. Its speed and cost-effectiveness in producing smaller quantities and custom parts make it ideal for prototyping and specialized manufacturing. This adoption by industry leaders has fueled consumer awareness and demand. Public libraries and retail stores are now offering 3D printing services, making the technology more accessible than ever. As printers become faster, more affordable, and capable of using a wider range of materials, 3D printing’s popularity and applications are set to explode.

Looking back to the 1980s, 3D printing was largely perceived as a tool for creating visual prototypes. However, thirty years of innovation have transformed the technology. Today, 3D-printed parts can meet industrial strength standards, demonstrating remarkable advancements in material science and printing precision. This progress has empowered hobbyists and vintage car enthusiasts to take restoration into their own hands, creating their own auto parts to revive and maintain classic vehicles.

3D Printing: Breathing New Life into Classic Cars

The automotive industry itself has experimented with and embraced 3D printing for vehicle manufacturing. Koenigsegg, a Swedish supercar manufacturer, showcased the Urbee in 2014, featuring bodywork and windows created using a 3D printer. The same year, Local Motors unveiled the Strati, a functional car with a chassis and body predominantly constructed from 3D-printed plastic and carbon fiber components. These examples highlight the growing capabilities and acceptance of 3D printing within automotive manufacturing.

For vintage car enthusiasts, 3D printing offers a particularly compelling solution to a persistent problem: the scarcity of parts. Restoring classic cars often involves a painstaking search for original or OEM replacement parts that are no longer in production. While classic car insurance provides financial protection, it doesn’t solve the logistical challenge of finding discontinued components. 3D printing empowers collectors to create custom-made parts, effectively circumventing the limitations of dwindling supply chains and inflated prices for rare components. Even with online marketplaces, locating certain vintage car parts remains incredibly difficult, and when found, they are often aged or used, compromising longevity and authenticity. 3D printing delivers a solution by enabling the creation of brand new parts to exact specifications.

It’s important to acknowledge that not all car parts are suitable for 3D printing, at least not with current desktop technologies. Critical components like engine blocks or wheel bearings, which endure extreme heat and stress, necessitate industrial machining processes and robust materials. However, 3D printing excels in the reproduction of smaller, often plastic, trim and accessory parts. Items such as door handles, interior knobs, dashboard trim pieces, and even cup holders are prime candidates for 3D printing. These are frequently the parts most susceptible to breakage and the hardest to source for older vehicles.

3D Printed Antique Car Parts: Precision and Accuracy

The process of 3D printing replacement parts for antique cars often begins with 3D scanning. The entire vehicle, or specific sections, can be meticulously scanned to capture every contour and detail. This comprehensive scan data is then processed and translated into CAD (Computer-Aided Design) drawings. These digital blueprints serve as instructions for the 3D printer. Using these CAD files, a 3D printer can then fabricate a replica part by precisely layering materials like plastic, metal composites, or carbon fiber. The result is an accurate reproduction of the original antique car part, adhering to the exact dimensions and specifications captured in the scan.

Artec 3D, a 3D scanning technology company, demonstrated the accuracy of this process by scanning a 1937 Ford Eifel, both inside and out. This detailed scan enabled the creation of a CAD model so precise that replacement parts could be manufactured without referencing original manufacturer specifications. This project successfully produced a new convertible top for this rare classic car, showcasing the potential of 3D scanning and printing in vintage car restoration. Artec 3D is actively expanding its efforts to scan more vintage vehicles, aiming to build a comprehensive digital archive. This archive would facilitate the on-demand 3D printing of rare collectible car parts based on accurate digital specifications. While vintage car insurance is essential for protecting these valuable vehicles, access to 3D printing technology provides an invaluable tool for preserving their physical integrity and originality.

Porsche, a manufacturer deeply connected to its heritage and classic models, has also embraced 3D printing. Recognizing the passionate community of Porsche enthusiasts who restore and maintain vintage models, Porsche has proactively addressed the challenge of dwindling spare parts inventories. While Porsche continues to stock spare parts for its classic cars, certain components for limited production models like the Porsche 959, 964, and 911 Speedster have become unavailable. To overcome this, Porsche has turned to 3D printing to remanufacture nine previously discontinued parts. Maintaining its commitment to quality, Porsche rigorously tests these 3D-printed parts to ensure they meet original equipment manufacturer (OEM) standards. The results have been positive, and Porsche is planning to expand its 3D parts printing operations, signifying a significant endorsement of the technology within the automotive industry.

Finding Your 3D Printed Modified Car Parts

For vintage car restorers looking to utilize 3D printing, whether to print parts themselves or source them from specialized providers, several reputable online marketplaces offer valuable resources. Here are three leading platforms:

Shapeways

Shapeways stands out as a comprehensive 3D printing service and marketplace. They offer on-demand 3D printing for a wide range of parts and maintain a marketplace featuring numerous classic car components. Shapeways aims to be a one-stop-shop for all 3D printing needs. For those who prefer not to invest in their own 3D printing equipment or lack the expertise, Shapeways provides a reliable option for obtaining high-quality 3D-printed vintage car parts, albeit at a premium compared to DIY printing.

MyMiniFactory

MyMiniFactory focuses on providing 3D printable models. They host a vast library of collectible car models ready for 3D printing. Users can download these models and use them to create parts for their restoration projects. It’s important to note that MyMiniFactory primarily offers digital models, not physical parts for sale directly on the platform. For individuals with access to FDM (Fused Deposition Modeling) 3D printers, MyMiniFactory provides a wealth of free resources to manufacture parts at home. The platform’s free download policy and extensive model library make it an excellent resource for 3D printing hobbyists and vintage car enthusiasts. While donations are encouraged to support the platform, the core resources are freely accessible.

Thingiverse

Thingiverse is an extremely popular and extensive website within the 3D printing community. It boasts a massive collection of 3D printable designs, including a significant selection of modified car parts and car-related accessories. Thingiverse encompasses virtually every type of 3D printable “thing” imaginable and is an essential online destination for anyone involved in 3D printing, particularly those seeking car parts and accessories.

The Horizon of 3D Printing in Car Restoration

3D printing is undoubtedly a transformative technology with staying power. We are witnessing only the initial phase of its potential, and further rapid advancements are anticipated. As 3D printing technology matures, we can expect to see even more affordable and higher-quality 3D-printed parts. This progress will further empower antique car owners, providing increasingly accessible solutions for sourcing those once-unattainable, hard-to-find vintage car parts, ensuring these classic vehicles can be preserved and enjoyed for generations to come.

Featured Image Credit: pxfuel

In Post Image Credit: Kholoudabdolqader / Wikimedia Commons