3D printing, a technology once confined to the realms of science fiction, has rapidly evolved into a transformative force across numerous industries. From rapid prototyping to creating intricate medical implants, its versatility is undeniable. In recent years, the automotive sector, particularly the world of classic car restoration, has begun to harness the power of 3D printing, offering enthusiasts and professionals alike unprecedented solutions for sourcing and creating parts. What was once a futuristic concept is now a tangible reality, breathing new life into vintage vehicles and ensuring their legacy for generations to come.

The Rise of 3D Printing in Automotive Restoration

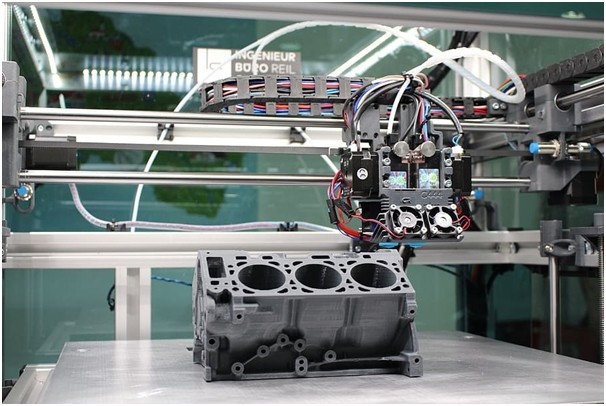

The journey of 3D printing, also known as additive manufacturing, began decades ago, but its mainstream adoption is a relatively recent phenomenon. Entry-level 3D printers are now accessible for home use at affordable prices, while industrial-grade machines are revolutionizing manufacturing processes. The core principle involves building three-dimensional objects layer by layer from materials like plastic, silicone, or carbon fiber, guided by digital designs. This method proves to be significantly faster and more cost-effective than traditional machining, especially for low-volume production runs or creating prototype parts for testing and refinement.

As 3D printing technology matured and became more accessible, its potential applications expanded dramatically. Major industries, including healthcare, aerospace, and automotive manufacturing, recognized its advantages. Parallel to this industrial growth, consumer interest surged, leading to public libraries and retail giants like Staples and UPS offering 3D printing services. This increased accessibility, coupled with advancements in printer speed and reduced operational costs, has paved the way for wider adoption and innovation.

In the early days, 3D printing was largely perceived as a tool for creating visual prototypes. However, thirty years of relentless innovation have transformed it into a viable method for producing functional, industrial-strength parts. The enhanced quality and accessibility of 3D printing technology have empowered hobbyists and professionals alike to create custom auto parts, particularly beneficial for the intricate process of restoring collectible cars where original components are often scarce or non-existent.

Solving the Classic Car Parts Dilemma with 3D Printing

The classic car restoration world presents unique challenges, primarily the daunting task of locating rare or discontinued parts. While classic car insurance can protect your investment, it cannot conjure up an obsolete OEM replacement part. This is where 3D printing emerges as a game-changer, providing a pathway for car collectors to fabricate their own components for modified or original vehicles. Even with the vast reach of online marketplaces, tracking down specific vintage car parts can be an arduous and often fruitless endeavor. When a part is eventually located, its age and condition are often questionable. 3D printing offers a compelling alternative: the ability to custom-manufacture brand new parts to exact specifications.

While certain critical components like engine blocks or wheel bearings, which endure extreme heat and stress, remain outside the scope of current home-based 3D printing capabilities and necessitate industrial machining, the technology excels at recreating smaller, often fragile, plastic accessories. Items such as door handles, interior knobs, dashboard trim pieces, and even cup holders are prime candidates for 3D printing. These smaller components are frequently the first to break or degrade over time and are notoriously difficult to replace in vintage vehicles.

The 3D Printing Process for Vintage Auto Components

The process of 3D printing a classic car part typically begins with a comprehensive scan of the original component or the area where the part is needed. Sophisticated 3D scanners meticulously capture every contour and dimension of the vehicle or part. This detailed scan data is then processed and transformed into Computer-Aided Design (CAD) drawings. These CAD files serve as blueprints for the 3D printer. The printer, utilizing these digital instructions, then employs a laser or other energy source to fuse successive layers of material – be it plastic, metal, or carbon fiber – precisely according to the CAD design. This additive process results in an identical replica of the original antique car part, adhering to the exact specifications.

A compelling example of this technology in action is demonstrated by Artec 3D, who successfully scanned a 1937 Ford Eifel, both inside and out, to create a complete CAD model. This digital twin enabled the creation of replacement parts without needing original manufacturer specifications, showcasing the remarkable accuracy of modern 3D printing. Artec 3D leveraged this capability to produce a new convertible top for this rare and valuable classic car. Driven by the potential to revolutionize classic car restoration, Artec 3D is expanding its efforts to scan more vintage vehicles, aiming to build a comprehensive digital archive. This archive would facilitate the on-demand 3D printing of rare collectible car parts based solely on their digital specifications. While vintage car insurance is essential for protecting these valuable assets, access to 3D printing technology provides an invaluable tool for maintaining and restoring them, ensuring parts availability that would otherwise be impossible.

Automakers Embrace 3D Printed Heritage Parts

Major automotive manufacturers are also recognizing the potential of 3D printing for preserving their heritage. Porsche, renowned for its dedicated community of classic car enthusiasts who actively restore and maintain vintage models, is a prime example. While Porsche diligently maintains a spare parts inventory for its classic cars, the stockpile of certain components has inevitably dwindled over time. Some parts, particularly for limited-production models, have become entirely unavailable. To address this challenge, Porsche turned to 3D printing to remanufacture nine previously discontinued parts for iconic models like the Porsche 959, 964, and 911 Speedster. Maintaining its rigorous quality standards, Porsche subjects all 3D-printed parts to stringent testing to ensure they meet original equipment manufacturer (OEM) specifications. Satisfied with the results, Porsche is actively planning to expand its 3D parts printing operations, signaling a long-term commitment to this innovative approach to heritage parts supply.

Where to Source 3D Printed Classic Car Parts and Models

For classic car enthusiasts seeking 3D printed parts, whether to print themselves or purchase готовые made components, several reputable online marketplaces have emerged. Here are three leading platforms:

Shapeways

Shapeways provides a comprehensive 3D printing service catering to a vast array of parts requests. They also host an extensive marketplace featuring thousands of classic car parts. Shapeways aims to be the ultimate destination for all 3D printing needs. For those who prefer not to engage in the printing process themselves, Shapeways offers a convenient option to purchase high-quality 3D printed parts, albeit at a premium compared to DIY printing.

MyMiniFactory

MyMiniFactory specializes in providing a vast database of collectible car models ready for 3D printing. Users can download these models and utilize them to create parts for their own projects. It is important to note that MyMiniFactory primarily offers digital models, not physical parts for sale. For users with access to an FDM 3D printer, MyMiniFactory enables the home-based manufacturing of a wide range of parts. Notably, MyMiniFactory offers its 3D models for free download, use, and distribution, making it an exceptionally valuable resource for hobbyists. While the service is free, users have the option to donate to support the platform. Beyond car parts, MyMiniFactory provides a rich collection of 3D models across various categories, making it a comprehensive resource for 3D printing enthusiasts.

Thingiverse

Thingiverse stands as an immensely popular platform within the 3D printing community. The website boasts an expansive selection of 3D printed modified car parts and a wide array of car-related accessories. With a virtually limitless collection of “things” imaginable, Thingiverse is an indispensable resource for anyone owning a 3D printer and seeking diverse models and designs.

The Future is 3D: Ensuring the Longevity of Classic Cars

The ascent of 3D printing is undeniable, and its transformative impact is just beginning to unfold. The coming years promise continued rapid advancements in 3D printing technology. 3D printed parts are poised to become even more affordable and of higher quality, democratizing access to previously elusive parts for antique car owners. This technology is not merely a trend; it is a fundamental shift in how we approach manufacturing and restoration, ensuring that the legacy of classic cars can be preserved and enjoyed for generations to come.

Featured Image Credit: pxfuel

In Post Image Credit: Kholoudabdolqader / Wikimedia Commons